English

Views: 222 Author: Astin Publish Time: 2025-04-13 Origin: Site

Content Menu

● Introduction to Aluminum Corner Profiles

>> Benefits of Using Aluminum Corner Profiles

● Preparation for Installation

>> Tools Needed

● Step-by-Step Installation Guide

>> Step 1: Measure and Cut the Profiles

>> Step 2: Prepare the Plywood Panels

>> Step 3: Attach the Profiles

● Handling Corners and Complex Shapes

>> Mitering Profiles for Corners

● Common Challenges and Solutions

● Advanced Techniques for Complex Projects

>> Curved Edges

● FAQ

>> 1. What are the benefits of using aluminum corner profiles?

>> 2. How do I handle corners when installing aluminum profiles?

>> 3. What tools are necessary for cutting aluminum profiles?

>> 4. Can I use adhesive to secure aluminum profiles?

>> 5. How do I ensure a precise fit for the profiles?

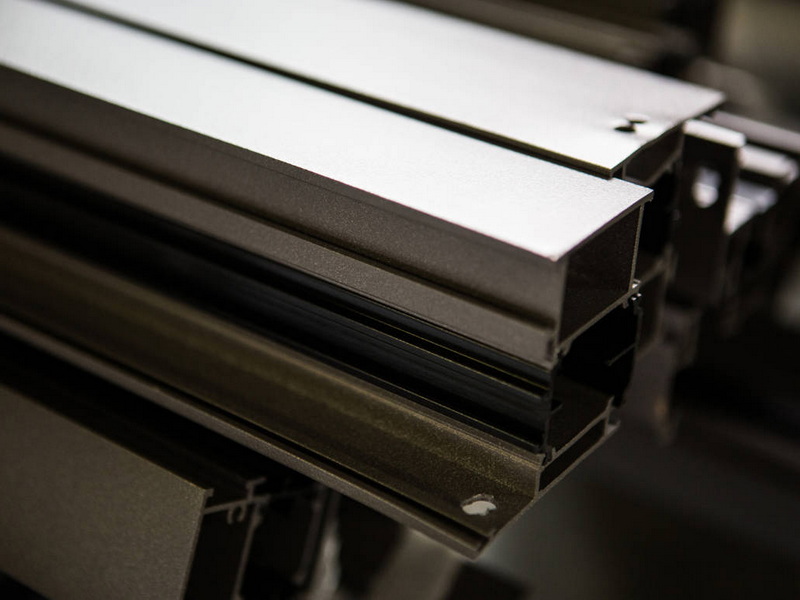

Installing aluminum corner profiles on plywood panels is a process that enhances the aesthetic appeal and durability of the panels, especially in applications such as furniture, cabinetry, and architectural features. Aluminum profiles provide a sleek, modern look while protecting the edges of the plywood from wear and tear. This article will guide you through the step-by-step process of installing aluminum corner profiles on plywood panels.

Aluminum corner profiles are designed to cover and protect the edges of plywood panels, providing a clean finish and preventing damage from moisture or physical impacts. These profiles are typically made from aluminum alloys, which are lightweight, corrosion-resistant, and easy to shape into various forms.

- Durability: Aluminum is resistant to corrosion and can withstand various environmental conditions.

- Aesthetics: Provides a sleek, modern appearance that can enhance the visual appeal of plywood panels.

- Protection: Safeguards the edges of plywood from chipping or cracking.

- Versatility: Available in different shapes and sizes to fit various types of corners and edges.

Before starting the installation, ensure you have all the necessary tools and materials.

- Tape Measure: For measuring the plywood panels and profiles.

- Miter Saw or Hacksaw: For cutting the aluminum profiles to size.

- Drill: For drilling holes if needed.

- Screwdriver or Drill Bits: For securing screws or clips.

- Adhesive (Optional): For bonding the profiles to the plywood.

- Clips or Brackets: Depending on the type of profile, these may be required for securing.

- Level: To ensure straight alignment during installation.

- Pencil and Marker: For marking the plywood and profiles.

- Aluminum Corner Profiles: These come in various shapes and sizes to fit different types of corners.

- Plywood Panels: Ensure they are clean and dry before installation.

- Screws or Clips: For securing the profiles to the plywood.

- Corner Pieces (Optional): For creating seamless corners.

- Filler Material (Optional): For filling gaps between profiles.

1. Measure the Plywood Edges: Use a tape measure to determine the length of the aluminum profiles needed. Consider adding a small margin for adjustments.

2. Cut the Profiles: Use a miter saw or hacksaw to cut the profiles to the required length. Ensure the cuts are clean and smooth.

1. Clean the Panels: Ensure the plywood edges are free from dust, dirt, or moisture.

2. Mark the Edges: If using screws or clips, mark the points where they will be attached. Use a pencil to avoid permanent marks.

3. Sand the Edges (Optional): Lightly sand the plywood edges to create a better surface for bonding or clipping.

1. Apply Adhesive (If Using): Apply a small amount of adhesive to the back of the profile if it is designed for bonding. Follow the manufacturer's instructions for application and drying times.

2. Secure with Clips or Brackets: If using clips or brackets, attach them to the plywood first, then slide or clip the profile into place. Ensure they are securely fastened.

3. Secure with Screws: If using screws, drill pilot holes to avoid splitting the plywood, then screw the profiles into place.

1. Inspect the Fit: Ensure the profiles fit snugly around the edges of the plywood.

2. Adjust as Needed: Make any necessary adjustments to ensure a smooth, even fit. Use a level to check for straightness.

Corners and complex shapes require special attention to ensure a seamless fit.

1. Select Corner Pieces: Choose corner pieces that match your profile type.

2. Attach Corner Pieces: Use screws or clips to secure the corner pieces, ensuring they are tightly fitted.

1. Cut at an Angle: Use a miter saw to cut the profiles at a 45-degree angle for smooth corner joints.

2. Assemble the Corner: Attach the mitered profiles to form a seamless corner. Use a small amount of adhesive if necessary to reinforce the joint.

During installation, you might encounter a few challenges. Here are some common issues and their solutions:

- Misaligned Profiles: Double-check your measurements and ensure the profiles are properly aligned before securing.

- Gaps Between Profiles: Use a filler material or adjust the profiles to eliminate gaps.

- Difficulty Cutting Profiles: Use the right cutting tools and techniques to avoid damaging the profiles.

- Loose Profiles: Check that all screws or clips are securely fastened. If using adhesive, ensure it has fully dried.

For more complex projects, such as curved edges or intricate designs, consider the following techniques:

1. Use Flexible Profiles: Some aluminum profiles are designed to be flexible, allowing them to conform to curved edges.

2. Bend Profiles: Use a profile bender or carefully heat and bend the profiles to fit curved shapes.

1. Use Custom Profiles: Consider custom-made profiles for unique shapes or designs.

2. Combine Profiles: Use multiple profiles to create complex shapes or patterns.

After installation, maintaining the aluminum corner profiles is relatively straightforward:

- Clean Regularly: Use a soft cloth and mild detergent to wipe down the profiles.

- Avoid Harsh Chemicals: Never use abrasive cleaners or chemicals that could damage the aluminum finish.

- Check for Damage: Periodically inspect the profiles for signs of wear or damage and repair as needed.

Installing aluminum corner profiles on plywood panels is a straightforward process that can significantly enhance the appearance and durability of your projects. By following the steps outlined in this guide, you can achieve professional-looking results even if you are a DIY enthusiast. Remember to choose the right tools and materials, and take your time to ensure a precise fit.

Aluminum corner profiles offer durability, aesthetic appeal, and protection for plywood edges. They are lightweight, corrosion-resistant, and easy to install.

For corners, you can either use pre-made corner pieces or miter the profiles at a 45-degree angle to create a smooth joint. Both methods ensure a seamless fit.

You can use a miter saw or a hacksaw with a fine-tooth blade to cut aluminum profiles. Ensure the cuts are clean and smooth to avoid damaging the profiles.

Yes, some aluminum profiles are designed to be bonded with adhesive. However, clips or screws are more common for securing profiles to plywood.

Measure carefully and double-check your cuts before assembling the profiles. Use a level to ensure straight alignment, and adjust as needed to achieve a snug fit.

[1] https://www.youtube.com/watch?v=FCUXYHmbYfE

[2] https://kladworx.com/aluminium-coping-installation-guide/

[3] https://www.shenghai-alu.com/article/how-to-install-aluminium-skirting-board-profile.47

[4] https://wiedehopf.ca/blog/aluminum-siding-installation/

[5] https://www.vst-lighting.com/how-to-install-aluminium-profiles-for-indirect-lighting/

[6] https://lt.shengfaalu.com/news/how-to-install-corner-pieces-in-the-aluminum-p-65995872.html

[7] https://www.thecornerguardstore.com/content/submittals/install/TCGS_Installation_Aluminum_Corner_Guards.pdf

[8] https://www.vst-lighting.com/installing-aluminium-profiles-for-led-tape/

[9] https://www.topledprofile.com/blog/a-step-by-step-guide-on-how-to-install-led-aluminum-profiles-230810c8-04eb-4951-a464-467a158c05d8

[10] https://www.ultimatereef.net/threads/attaching-ply-board-to-aluminium-profile-stand.920504/

[11] https://sprinter-source.com/forums/index.php?threads%2F120429%2F

[12] https://www.arcpanels.com/wp-content/uploads/2021/06/2-mechanical-Recommended-Installation-Guide-1.pdf

[13] https://sprinter-source.com/forums/index.php?threads%2F125893%2F

[14] https://www.newtechwood.uk/wp-content/uploads/Wall-Cladding-US31-Installation-Guide-Vertical-Horizontal-1.pdf

[15] https://www.mebel-alu.com/news/a-step-by-step-guide-to-installing-frame-aluminum-profiles/

[16] https://www.plywoodandpanel.com.au/wp-content/uploads/2019/12/Shadowclad-Cavity-Construction-Specification-Installation-Guide-Sept-2015-AU.pdf

[17] https://www.reddit.com/r/DIY/comments/1b133ei/how_to_attach_aluminum_extrusion_to_wood_desk/

[18] https://www.unilinpanels.com/en/interior/wall-cladding-accessories/clicwall-alu-profile-outercorner

[19] https://eagle-aluminum.com/aluminum-corner-trims-the-perfect-solution-for-wall-corners/

[20] https://cdn.atkar.com.au/wp-content/uploads/2019/09/26111336/DesignerWood-Alu-VENEER-Install-Guide-WEB-v1.1.pdf

[21] https://www.youtube.com/watch?v=Klb9fVN56Uw

[22] https://shop.machinemfg.com/how-to-join-aluminium-frame-a-step-by-step-guide/

[23] https://gtoaluminum.com/installing-aluminum-cladding/

[24] https://www.linkedin.com/pulse/comprehensive-guide-using-aluminum-profiles-led-strips-mylikeled-5a8lc

[25] https://www.tuli-shop.com/blog/how-to-join-aluminium-profiles.html

[26] https://woodupp.com/guides/aluwood-installation-guide/

[27] https://www.reddit.com/r/simracing/comments/1fohzqg/suggestion_for_connecting_different_aluminium/

[28] https://www.europrofiles.com.au/faqs.php

[29] https://www.profilepanels.co.nz/pages/faqs

[30] https://www.weiye-aluminium.com/what-are-the-benefits-of-custom-aluminum-corner-profiles.html

[31] https://www.krcaluprofiles.com/blog/step-by-step-guide-to-aluminium-edge-profile-installation/

[32] https://www.part-on.co.uk/blog/post/6-ways-to-connect-join-aluminium-extrusion/

[33] https://engineerswhovanlife.com/fastening-panels-to-8020/

[34] https://www.youtube.com/watch?v=Ys4bcJJ2cAE

[35] https://ameriluxinternational.com/wp-content/uploads/2021/pdf-downloads/install-guides/amerilux-base-cap-install-guide.pdf

[36] https://www.otalum.com/4-common-installation-methods-of-industrial-aluminum-profile-connectors.html

[37] https://tbafirefly.com.au/wp-content/uploads/2025/02/Solid-Aluminium-Cladding-Guide.pdf

Why Aluminum Profiles Are the Backbone of Modern Engineering?

Extrusion is the basis for producing high-quality aluminum profiles

Top Aluminum Windows Manufacturers and Suppliers in Saudi Arabia

Top Aluminum Windows Manufacturers and Suppliers in Indonesia

Top Aluminum Windows Manufacturers and Suppliers in Malaysia

Common alloy series and performance analysis of aluminum profiles