English

Views: 222 Author: Astin Publish Time: 2025-05-11 Origin: Site

Content Menu

● Understanding Aluminum Profile Accessories

● Fasteners: The Foundation of Assembly

● Connectors and Joints: Building Structural Integrity

>> Types of Connectors and Joints

● Brackets: Reinforcing and Supporting Structures

● End Caps and Slot Covers: Finishing and Protection

>> Applications

● Feet and Supports: Stability and Leveling

● Handles, Hinges, and Functional Accessories

>> Common Functional Accessories

>> Applications

● Decorative and Protective Accessories

>> Types

>> Benefits

● Selecting the Right Accessories: Key Considerations

● Maintenance and Longevity of Aluminum Profile Accessories

● Innovations in Aluminum Profile Accessories

● Frequently Asked Questions (FAQ)

>> 1. What are the most common types of aluminum profile accessories?

>> 2. How do I choose the right accessory for my aluminum profile project?

>> 3. Can aluminum profile accessories be reused or reconfigured?

>> 4. What materials are used for aluminum profile accessories?

>> 5. Are there accessories for specialized applications like automation or clean rooms?

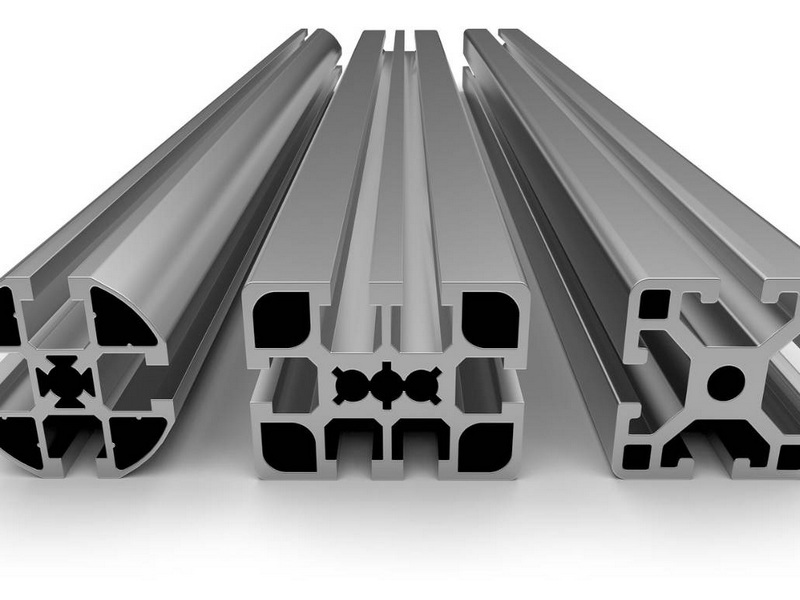

Aluminum profiles have revolutionized the way modern structures, frameworks, and machinery are assembled. Their modularity, strength, and lightweight nature make them indispensable across industries ranging from manufacturing and automation to architecture and interior design. However, the true versatility of aluminum profiles is unlocked only through the use of specialized accessories. These accessories not only facilitate the assembly process but also enhance the functionality, safety, and aesthetics of the finished product.

This comprehensive guide explores the most essential aluminum profile accessories, detailing their types, functions, applications, and the critical role they play in modular construction systems. Whether you are a designer, engineer, or DIY enthusiast, understanding these accessories is key to maximizing the potential of aluminum profile systems.

Aluminum profile accessories are the backbone of modular assembly systems. They are designed to connect, reinforce, and finish aluminum profile structures without the need for welding or complex machining. By enabling quick, flexible, and robust assembly, these accessories make it possible to create everything from simple frames to intricate automated machinery.

The main categories of essential aluminum profile accessories include:

- Fasteners (bolts, nuts, screws)

- Connectors and joints

- Brackets

- End caps and slot covers

- Feet and supports

- Handles, hinges, wheels, and other functional components

Each category serves a distinct purpose in the assembly and operation of aluminum profile structures. Let's explore these categories in detail.

Fasteners are the most fundamental accessories for aluminum profiles. They include bolts, nuts, screws, and washers, and are responsible for securely joining profiles and components together.

- T-Bolts and T-Nuts: Designed to fit into the T-slots of aluminum profiles, allowing for secure and adjustable connections.

- Hammerhead Nuts: Slide into the profile slot and provide a strong anchor point for bolts.

- Sliding Nuts: Inserted into the slot and can be positioned anywhere along the profile for flexible assembly.

- Hexagon Socket Bolts: Common for joining profiles at various angles.

- Flange Nuts: Used in conjunction with bolts for added stability.

Fasteners are indispensable for:

- Assembling frames, workbenches, and enclosures

- Attaching panels, doors, or accessories to profiles

- Providing adjustable and modular connections

Their ease of installation and reusability make them ideal for systems that require frequent modifications or expansions.

Connectors and joints are specialized accessories that link two or more profiles, ensuring structural integrity and enabling complex configurations.

- Internal Connectors: Hidden inside the profile, providing a clean external appearance.

- External Connectors: Mounted on the outside, often used for heavy-duty applications.

- Angle Joints (L and E joints): Allow for perpendicular or angled connections between profiles.

- Articulated Joints: Enable movement and flexibility, ideal for adjustable structures.

- Multi-way Connectors: Join three or more profiles at a single point, useful for complex frameworks.

Connectors and joints are essential for:

- Creating right-angle, T-shaped, or multi-directional connections

- Ensuring rigidity and stability in large or load-bearing structures

- Allowing for dynamic movement in adjustable frames or machinery

Their variety enables designers to create virtually any configuration without the need for welding or permanent modification.

Brackets are support accessories that reinforce connections and provide additional strength at critical junctions.

- Corner Brackets: Used for 90-degree connections, available in various sizes to match profile series.

- Heavy Brackets: Designed for joining multiple vertical profiles or supporting heavy loads.

- Foundation Brackets: Attach the structure to the floor or base for added stability.

- Oblique Angle Brackets: Allow for connections at non-standard angles, such as 45° or 135°.

Brackets are crucial for:

- Strengthening joints and preventing movement or deformation

- Supporting shelves, panels, or equipment mounted on profiles

- Creating stable bases for machinery, conveyors, or workstations

Their robust construction ensures long-term durability and safety in demanding environments.

End caps and slot covers are often overlooked but are vital for both aesthetics and protection.

- End Caps: Snap into the open ends of profiles, providing a finished look and preventing the ingress of dust, debris, or moisture.

- Slot Covers (Profile Covers): Made from plastic or rubber, these cover the open T-slots, protecting internal components and improving the appearance of the structure.

- Enhancing the visual appeal of exposed profiles

- Protecting users from sharp edges

- Preventing contamination in clean environments, such as laboratories or food processing facilities

Their easy installation and low cost make them a must-have for any aluminum profile assembly.

Feet and supports are accessories that provide stability, leveling, and mobility to aluminum profile structures.

- Fixed Feet: Provide stable support for stationary structures.

- Articulated Feet: Allow for leveling on uneven surfaces.

- Anti-Vibration Feet: Reduce noise and vibration, ideal for machinery.

- Castors (Wheels): Add mobility for workstations, carts, or equipment.

- Ensuring structures are level and secure

- Distributing weight evenly to prevent tipping or collapse

- Facilitating movement and repositioning of mobile assemblies

Selecting the right type of foot or support is essential for safety and operational efficiency.

Beyond structural components, aluminum profile systems can be enhanced with a range of functional accessories.

- Handles: For opening doors, drawers, or moving assemblies.

- Hinges: Enable doors or panels to swing open or closed.

- Wheels and Castors: Provide mobility.

- Panel Holders and Clamps: Secure panels, glass, or other materials to the frame.

- Cable Trays and Guides: Organize and protect wiring within the structure.

- Improving ergonomics and usability

- Adding doors, access panels, or movable elements

- Managing cables and hoses in automated systems

These accessories increase the versatility and user-friendliness of aluminum profile assemblies.

While functionality is paramount, decorative and protective accessories also play a significant role.

- Cover Strips: Snap into T-slots to hide fasteners and improve appearance.

- Joint Covers: Conceal and protect joints from dust and wear.

- Protective Buffers: Absorb impact and reduce damage to profiles or attached components.

- Enhance the professional look of finished assemblies

- Protect sensitive components and prolong lifespan

- Ensure compliance with safety and hygiene standards

When choosing aluminum profile accessories, consider the following factors:

- Compatibility: Ensure accessories match the profile series and slot size.

- Material: Select materials (aluminum, steel, plastic) based on strength, corrosion resistance, and application environment.

- Load Requirements: Choose brackets, connectors, and feet rated for the expected loads.

- Assembly Method: Decide between permanent or adjustable connections based on future modification needs.

- Aesthetics: Consider end caps, covers, and decorative elements for visible structures.

Proper selection and installation of accessories are crucial for achieving a safe, functional, and visually appealing result.

Maintaining aluminum profile accessories is straightforward but essential for ensuring long-term performance:

- Regular Inspection: Check for loose fasteners, worn components, or damage.

- Cleaning: Remove dust and debris from slots, covers, and moving parts.

- Lubrication: Apply lubricant to hinges, wheels, and articulated joints as needed.

- Replacement: Replace damaged or worn accessories promptly to maintain structural integrity.

With proper care, high-quality accessories can last for years, even in demanding industrial environments.

The field of aluminum profile accessories continues to evolve, with new designs and materials enhancing performance and ease of use:

- Quick-Connect Fasteners: Enable tool-free assembly and disassembly.

- Modular Cable Management: Integrated trays and guides for streamlined wiring.

- Smart Accessories: Sensors and actuators for automated systems.

- Eco-Friendly Materials: Recycled plastics and sustainable finishes.

Staying informed about the latest innovations can help you build more efficient, adaptable, and sustainable systems.

Aluminum profile accessories are the unsung heroes of modular construction and assembly. From fasteners and connectors that provide structural integrity, to brackets, end caps, and functional components that enhance usability and aesthetics, these accessories are essential for unlocking the full potential of aluminum profile systems.

By understanding the types, functions, and selection criteria for these accessories, you can design and build robust, flexible, and visually appealing structures tailored to your specific needs. Whether you are assembling a simple frame or a complex automated machine, investing in high-quality aluminum profile accessories is key to achieving long-lasting, efficient, and adaptable solutions.

The most common types include fasteners (T-bolts, T-nuts, screws), connectors and joints (internal, external, angle, articulated), brackets (corner, heavy-duty, foundation), end caps, slot covers, feet, handles, hinges, wheels, and panel holders.

Consider the profile series and slot size, the load and application requirements, the environment (indoor/outdoor, exposure to chemicals), and whether you need adjustable or permanent connections. Always ensure compatibility between accessories and profiles.

Yes, one of the main advantages of aluminum profile systems is their modularity. Most accessories can be loosened, repositioned, or replaced without damaging the profiles, allowing for easy reconfiguration and expansion.

Accessories are commonly made from aluminum alloys, steel (galvanized or stainless), zinc alloys, and high-strength plastics such as nylon or PVC. The choice depends on the required strength, corrosion resistance, and application environment.

Yes, there are specialized accessories such as anti-vibration feet for machinery, cable trays for automation, and protective covers for clean rooms. Always consult with your supplier for application-specific solutions.

Top Aluminum Profiles Manufacturers and Suppliers in Czech Republic

Top Aluminum Profiles Manufacturers and Suppliers in Belgium

Top Aluminum Profiles Manufacturers and Suppliers in Finland

Top Aluminum Profiles Manufacturers and Suppliers in Denmark

Top Aluminum Profiles Manufacturers and Suppliers in Portugal