English

Views: 222 Author: Astin Publish Time: 2025-07-27 Origin: Site

Content Menu

● The Rise of Aluminum Profiles Manufacturing in Poland

● Why Choose Polish Aluminum Profiles Manufacturers and Suppliers?

● Leading Aluminum Profiles Manufacturers and Suppliers in Poland

● Export Capabilities and International Partnerships

● The OEM/ODM Advantage in the Polish Aluminum Industry

● Applications of Polish Aluminum Profiles

● Quality Standards and Certification

● Sustainability and Environmental Stewardship

● How to Choose the Right Aluminum Profiles Supplier in Poland

● FAQ

>> 1. What are the main advantages of choosing Polish Aluminum Profiles Manufacturers and Suppliers?

>> 2. Can Polish aluminum suppliers handle custom or private-label projects for international clients?

>> 3. What industries are served by Aluminum Profiles Manufacturers and Suppliers in Poland?

>> 4. Are Polish aluminum profiles environmentally friendly?

Poland, a country renowned for its robust industrial capabilities and central position in the heart of Europe, has long been a focal point for various manufacturing sectors. Among these, the aluminum profiles manufacturing industry stands out due to its rapid growth, technological excellence, and the high demand for aluminum-based products across construction, transportation, furniture, industrial, and architectural applications. This article delves deep into the thriving world of Aluminum Profiles Manufacturers and Suppliers in Poland, guiding global brands, importers, and OEM/ODM clients toward the region's leading providers.

Aluminum profiles have become indispensable in modern construction and manufacturing, recognized for their versatility, strength, light weight, corrosion resistance, and aesthetic flexibility. Poland, with an expanding industrial base, skilled workforce, and favorable business environment, has emerged as a top hub for Aluminum Profiles Manufacturers and Suppliers, serving both domestic and international markets.

Investment in advanced extrusion technology, commitment to sustainable operations, and a strong export orientation have enabled Polish manufacturers to compete at the highest European and global levels. The sector's annual growth is driven by rising demand for eco-friendly, customizable, and innovative aluminum solutions.

Poland's aluminum profiles manufacturers and suppliers are celebrated for several distinguishing factors including:

- High-Quality Standards: Producers adhere strictly to European Union standards and international certifications, providing reliable and durable products for a range of industries.

- Cutting-Edge Technology: Polish manufacturers utilize state-of-the-art extrusion presses, precision machining, and surface finishing techniques that enable highly complex and customized profiles.

- Sustainability Initiatives: Many suppliers focus on using recycled aluminum, energy-efficient processes, and responsible waste management to deliver eco-friendly solutions.

- Diverse Product Portfolios: From standard architectural sections to tailor-made OEM/ODM profiles, Polish companies offer a wide spectrum of aluminum products.

- Strategic Location: Central European location allows for efficient logistics, streamlined delivery times, and strong connectivity with the EU market and beyond.

The range of products offered by Aluminum Profiles Manufacturers and Suppliers in Poland typically includes:

- Standard Profiles: Angles, tubes, T-tracks, U-channels, and flat bars for general industrial use.

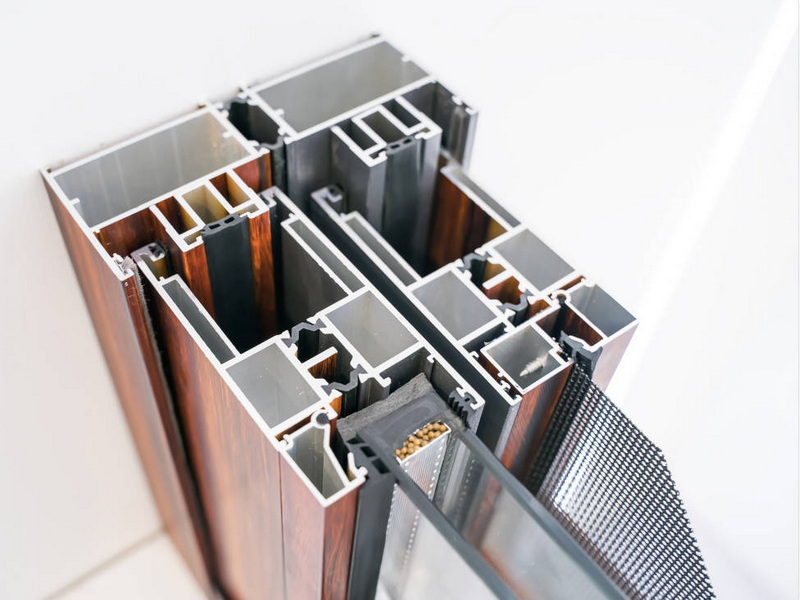

- Construction Systems: Profiles for doors, windows, façades, curtain walls, and modular office systems.

- Automotive and Transport: Lightweight, strong aluminum extrusions for vehicles, railway, and logistics infrastructure.

- Furniture and Interior Design: Decorative and structural sections for modern furniture frames and fittings.

- Custom OEM/ODM Profiles: Designed and manufactured to specific customer requirements, covering a vast range of industries.

Poland's aluminum industry features both well-established giants and dynamic, innovation-driven firms specializing in OEM, ODM, and private-label production. Below are prominent names recognized for their quality, reliability, and international reach:

One of the largest conglomerates in the Polish aluminum sector, Grupa Kęty S.A. is acclaimed for its integrated aluminum solutions, from extruded profiles to complex architectural systems. The company's cutting-edge facilities produce profiles for construction, transport, and electronic industries, consistently meeting international standards.

Yawal is a pioneering company focusing on the design and production of aluminum architectural systems. Its offer includes windows, doors, curtain walls, and façade profiles, customized to meet the needs of modern architecture. Their OEM/ODM capabilities allow international clients to collaborate on exclusive projects.

A subsidiary of Grupa Kęty, Aluprof is another heavyweight in the market, specializing in high-performance aluminum systems for building façades, doors, windows, and sun protection. Their strong R&D department and global export network make them a favored partner for large-scale projects around the world.

Renowned for its modern production lines and commitment to sustainability, Alumetal Group offers a wide array of aluminum alloys and profiles for automotive, construction, and industrial customers. Their advanced recycling processes ensure high ecological standards.

A prominent Aluminum Profiles Manufacturer and Supplier, Extral S.A. provides standard and custom extruded profiles for furniture, electrical, and engineering sectors. They are noted for their flexibility in supporting OEM/ODM partners.

While mainly known for its glass manufacturing, Press-Glas also produces high-quality aluminum profiles for window and curtain wall systems, integrating these into their award-winning architectural solutions.

A progressive company offering tailor-made aluminum solutions, Final S.A. excels in producing profiles for machinery, renewable energy, and transport sectors. Precision, innovation, and client partnership are the hallmarks of their approach.

Aluminum Profiles Manufacturers and Suppliers in Poland have established themselves as reliable partners for foreign brands, wholesalers, and OEM/ODM clients, thanks to their:

- Strong Export Infrastructure: Efficient sea, rail, and road links for global delivery.

- Multilingual Support: Companies offer customer service in multiple languages to foster easy communication and partnership with international clients.

- Flexible Manufacturing: Adaptable production lines and low MOQ (minimum order quantity) options for specialized projects.

- After-Sales Service: Comprehensive technical assistance, design support, and warranty services.

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services have become a critical pillar of Poland's aluminum industry competitiveness. Aluminum Profiles Manufacturers and Suppliers offer:

- Private-label Manufacturing: Allowing brand owners to create exclusive aluminum product lines.

- Custom Design Engineering: Collaborating closely with client R&D for innovative product development.

- Prototyping and Rapid Sampling: Accelerating the path from concept to market.

- Brand Collaboration: Seamless integration with client branding, packing, and documentation needs.

This strategic flexibility makes Polish manufacturers ideal for companies seeking cost-effective, high-quality production with full confidentiality and IP protection.

The versatility of aluminum profiles enables their application in diverse sectors:

- Construction and Real Estate: Window frames, curtain walls, canopies, partition systems.

- Automotive and Transportation: Trailers, automotive parts, railway carriages.

- Industrial Machinery: Machine frames, conveyor systems, protective railings.

- Furniture and Shop Fittings: Modern furniture aesthetics, modular shelving, store displays.

- Renewable Energy: Solar panel frames and mounting structures.

Poland's Aluminum Profiles Manufacturers and Suppliers have invested heavily in advanced technology:

- High-precision Extrusion: CNC-controlled shaping for intricate cross-sections.

- Anodization and Powder Coating: Providing enhanced corrosion resistance and color versatility.

- Thermal Break Technology: Improving insulation properties for energy-efficient building profiles.

- Automation and Smart Manufacturing: Utilizing robots and AI for process optimization and consistent quality.

To ensure reliability and international competitiveness, Polish aluminum producers maintain:

- ISO 9001 Quality Management System

- ISO 14001 Environmental Management System

- EN 12020, EN 755, EN 15088 Compliance for structural and architectural aluminum profiles

These certifications guarantee that each product meets strict criteria for mechanical strength, durability, and safety.

Sustainability is a top priority for modern Polish aluminum profiles manufacturers and suppliers. Practices include:

- Utilizing Recycled Aluminum: Significantly reducing energy use and carbon footprint.

- Eco-Friendly Surface Treatments: Using non-toxic, low-VOC processes.

- Waste Minimization: Advanced filtration, recycling, and resource optimization throughout production.

By adhering to green manufacturing principles, Polish suppliers help clients reduce their own environmental impacts and meet the most stringent international standards.

Selecting the ideal Aluminum Profiles Manufacturer and Supplier in Poland depends on specific project needs. Key considerations include:

- Production Capacity: Ensure the supplier can fulfill both current needs and future growth plans.

- Customization Capability: Evaluate their record of OEM/ODM projects and design flexibility.

- Quality Assurance: Verify compliance with international standards and customer references.

- Lead Times and Logistics: Assess their delivery timelines and global shipping capability.

- Customer Support: Strong after-sales service and transparent communication.

- Sustainability Commitment: Check their environmental policies, particularly if green certifications are important.

Personal visits, factory audits, and product sampling are recommended to confirm capabilities before establishing long-term partnerships.

The future of Aluminum Profiles Manufacturers and Suppliers in Poland is exceptionally promising. Ongoing investments in R&D, a growing focus on lightweight sustainable solutions, and increasing demand from sectors such as electric vehicles, green building, and logistics bode well for industry expansion.

With continued globalization, Poland is expected to remain a strategic partner for international brands and wholesalers seeking innovative, reliable, and environmentally responsible aluminum solutions.

Poland has firmly positioned itself as a leading destination for Aluminum Profiles Manufacturers and Suppliers, offering a competitive mix of quality, technology, flexibility, and global accessibility. Whether you are a brand owner, wholesaler, or factory seeking OEM/ODM partnership, Polish aluminum suppliers provide high-value, sustainable, and customizable options suited for the international market.

Polish manufacturers stand out for their high technical standards, reliable quality, ability to fulfill bespoke OEM/ODM requests, and strategic location that facilitates swift distribution across Europe and abroad. Their environmental commitment also appeals to clients focused on sustainability.

Yes, many leading Aluminum Profiles Manufacturers and Suppliers in Poland offer OEM and ODM services, tailoring designs and branding to your specifications, and providing confidentiality for new product launches.

A broad spectrum of industries rely on Polish aluminum profiles, including construction, automotive, rail transport, furniture, industrial machinery, renewable energy, and consumer goods sectors.

Most reputable Polish manufacturers use recycled aluminum, energy-efficient production processes, and environmentally responsible surface treatments to minimize their environmental footprint, delivering eco-friendly products that meet international standards.

Start by researching and shortlisting qualified suppliers, initiate direct communication, clarify your product specifications, request samples or prototypes, and, if feasible, arrange a factory visit or audit to assess quality and process control.