English

Views: 222 Author: Astin Publish Time: 2025-03-19 Origin: Site

Content Menu

● Introduction to Aluminum Extrusion Profiles

>> Key Benefits of Aluminum Extrusion Profiles

● Applications of Aluminum Extrusion Profiles

>> Automotive and Aerospace Industries

● Comparison with Steel Extrusions

● Choosing the Right Aluminum Extrusion Profile

● Maintenance and Longevity of Aluminum Extrusion Profiles

● Real-Life Applications and User Experiences

● Expanded Applications in the Automotive Industry

● Future Innovations in Aluminum Extrusion

● Case Studies: Successful Integration of Aluminum Extrusions

● FAQs

>> 1. What are the primary advantages of using aluminum extrusion profiles in structural applications?

>> 2. How do aluminum extrusions compare to steel in terms of strength?

>> 3. What surface treatments can enhance the durability of aluminum extrusions?

>> 4. Are aluminum extrusions environmentally friendly?

>> 5. How do I ensure the longevity of aluminum extrusion profiles?

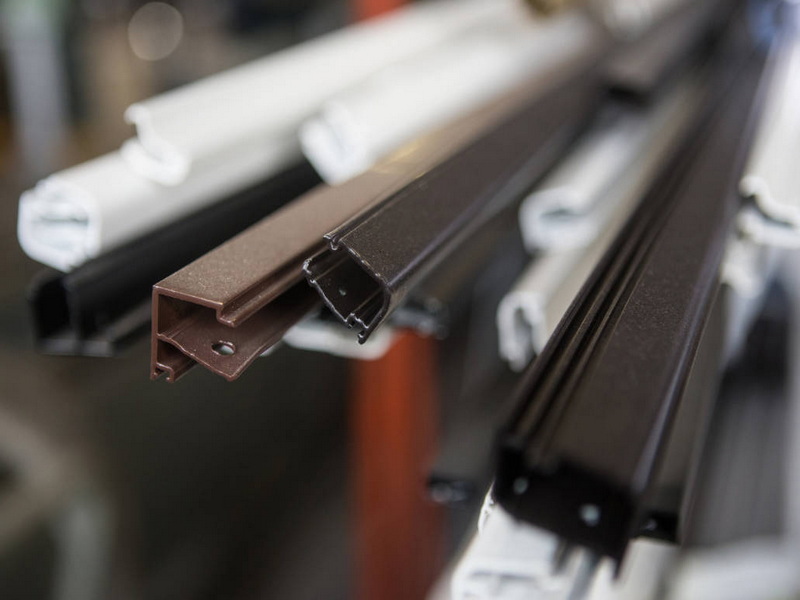

Aluminum extrusion profiles have become a staple in various industries, including construction, automotive, and aerospace, due to their versatility, strength, and lightweight properties. These profiles are created through a process where aluminum alloy is heated and forced through a die to achieve specific shapes, making them highly customizable for different structural applications. This article will explore the benefits of using standard aluminum extrusion profiles for structural purposes, highlighting their advantages, applications, and how they compare to other materials like steel.

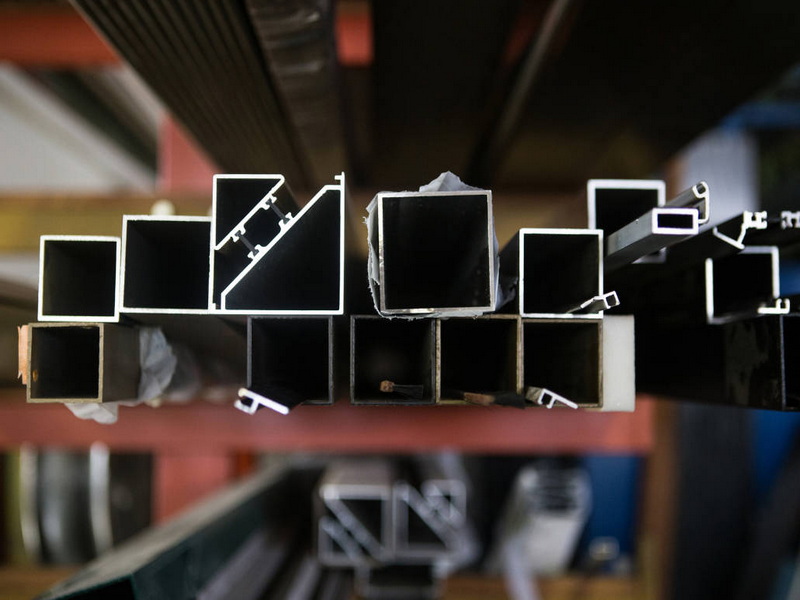

Aluminum extrusion profiles are made by extruding aluminum alloy through a die under high pressure, resulting in a continuous profile with precise dimensions. This process allows for the creation of complex shapes that cannot be achieved with other materials, making aluminum extrusions ideal for applications requiring unique structural designs.

1. Lightweight and Strong: Aluminum profiles offer a high strength-to-weight ratio, making them suitable for applications where weight reduction is crucial, such as in aerospace and automotive industries.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing excellent corrosion resistance, which can be further enhanced with surface treatments like anodizing or powder coating.

3. Customizability: The extrusion process allows for the creation of custom shapes tailored to specific project requirements, offering greater design flexibility.

4. Sustainability: Aluminum is highly recyclable and requires less energy for production compared to other materials, making it an environmentally friendly choice.

Aluminum extrusion profiles are widely used in construction for window frames, door frames, curtain walls, and roofing structures due to their strength, durability, and resistance to corrosion. They are particularly beneficial for large commercial buildings as they reduce structural loads, enhancing safety and reducing construction costs.

In the automotive sector, aluminum extrusions are used for chassis components and suspension parts due to their lightweight yet robust properties. In aerospace, they are utilized for structural components where weight reduction is critical.

Aluminum extrusions are also used in industrial settings for equipment frames, machine guarding systems, and workstations due to their ease of assembly and corrosion resistance.

When comparing aluminum with steel extrusions, several factors come into play:

1. Strength: Steel offers higher tensile strength, making it suitable for heavy-duty applications like bridges and heavy machinery.

2. Weight: Aluminum is significantly lighter than steel, ideal for applications where weight reduction is necessary.

3. Corrosion Resistance: Aluminum naturally resists corrosion better than steel, although stainless steel can offer similar resistance.

4. Cost: Aluminum extrusions are generally more expensive than steel due to production costs, but they offer long-term benefits like reduced maintenance and energy efficiency.

When selecting aluminum extrusion profiles for structural applications, consider the following factors:

1. Material Properties: Ensure the alloy used provides the necessary strength and corrosion resistance for your application.

2. Shape and Design: Choose profiles that match your structural needs, taking advantage of the customization offered by the extrusion process.

3. Surface Treatment: Apply appropriate coatings to enhance corrosion resistance and aesthetic appeal.

4. Sustainability: Consider the environmental impact and recyclability of aluminum.

To ensure the longevity of aluminum extrusion profiles, regular maintenance is essential. This includes cleaning the profiles to prevent dirt buildup and applying protective coatings to maintain corrosion resistance. Additionally, inspecting for signs of wear or damage can help extend their lifespan.

Many industries have successfully integrated aluminum extrusion profiles into their projects. For instance, in construction, these profiles have been used to create modular building systems that are both efficient and sustainable. In the automotive sector, they have contributed to lighter vehicle designs, enhancing fuel efficiency and performance.

Aluminum extrusions in the automotive sector are not limited to structural components; they are also used in vehicle design for parts like seat frames and display stands. The use of aluminum has contributed significantly to reducing vehicle weight, which in turn improves fuel efficiency and enhances overall performance. Furthermore, the customizability of aluminum extrusions allows for innovative designs that improve passenger safety and comfort.

Advancements in aluminum extrusion technology are continually expanding its applications. For instance, new alloys are being developed with enhanced strength and corrosion resistance, making them suitable for even more demanding environments. Additionally, innovations in surface treatments are improving the aesthetic appeal and durability of aluminum profiles, further increasing their versatility. These advancements are expected to open up new markets and applications for aluminum extrusions, particularly in emerging industries like renewable energy and advanced manufacturing.

Several companies have successfully integrated aluminum extrusions into their products, showcasing the versatility and benefits of these profiles. For example, a leading automotive manufacturer used aluminum extrusions to create a lightweight yet robust chassis, resulting in improved fuel efficiency and reduced emissions. In the aerospace industry, aluminum extrusions have been used in satellite components due to their high strength-to-weight ratio and resistance to extreme temperatures.

Aluminum extrusion profiles offer a versatile and efficient solution for structural applications across various industries. Their lightweight yet strong properties, combined with excellent corrosion resistance and customizability, make them an ideal choice for projects requiring both functionality and sustainability. Whether in construction, automotive, or aerospace, aluminum extrusions provide long-term benefits that outweigh their initial costs, making them a valuable investment for any project.

The primary advantages include their lightweight yet strong properties, excellent corrosion resistance, and customizability, making them suitable for a wide range of applications.

Steel offers higher tensile strength, making it more suitable for heavy-duty applications, while aluminum is lighter and ideal for weight-sensitive projects.

Surface treatments like anodizing and powder coating can significantly enhance corrosion resistance and aesthetic appeal.

Yes, aluminum is highly recyclable and requires less energy for production compared to other materials, making it an environmentally friendly choice.

Regular cleaning, applying protective coatings, and inspecting for signs of wear or damage can help extend their lifespan.

[1] https://www.otalum.com/several-significant-advantages-of-aluminum-extruded-profiles.html

[2] https://jmaluminium.com/exploring-the-world-of-aluminium-extrusion-profiles-what-they-are-and-how-theyre-used/

[3] https://www.china-me.com/news/article/common-applications-of-industrial-aluminum-extrusion

[4] https://www.weiye-aluminium.com/what-are-the-benefits-of-using-extruded-aluminum-profiles-in-construction.html

[5] https://www.alineautomation.com/the-difference-between-steel-and-aluminum-extrusion/

[6] https://profileprecisionextrusions.com/why-aluminum-extrusions-are-better-than-stainless-steel-6-reasons-to-choose-aluminum-over-stainless/

[7] https://blog.okorder.com/the-benefits-of-aluminum-extrusion-for-building-profiles/

[8] https://aec.org/features-benefits

[9] https://anglelock.com/blog/metal-framing-systems-welded-steel-aluminum-extrusion

[10] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[11] https://www.profall.com/en/blog/the-difference-between-steel-and-aluminum-comparing-profiles

[12] https://www.linkedin.com/pulse/understanding-different-types-standard-aluminum-extrusion-njvrc

[13] https://www.zahit.com.tr/what-is-aluminum-extrusion-profile-what-are-the-features-and-areas-of-usage

[14] https://www.yjing-extrusion.com/what-are-the-key-benefits-of-using-aluminum-extrusion-profiles-in-construction.html

[15] https://www.shengxinglobal.com/blog/aluminum-extrusion-profiles-the-definitive-guide-2025.html

[16] https://www.mornglass.com/the-application-of-aluminium-profiles-in-building.html

[17] https://www.tuli-shop.com/blog/aluminum-extrusion-and-applications-guide.html

[18] https://www.retop-industry.com/news/aluminum-extrusions-profiles.html

[19] https://www.hydro.com/profiles/uses-of-aluminum-extrusions

[20] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-applications-of-aluminum-extrusion-profiles-in-various-industries/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden