English

Views: 222 Author: Astin Publish Time: 2025-04-17 Origin: Site

Content Menu

● Understanding the Importance of Heat Sinks for LEDs

● Why Aluminum Is the Preferred Material for LED Heat Sinks

● Types of Aluminum Heat Sink Profiles for LEDs

>> 2. Finned Heat Sink Profiles

>> 3. Corner and Angular Profiles

>> 4. Recessed (Flush-Mount) Profiles

>> 5. Custom Extruded Profiles

● Key Design Features of Effective LED Aluminum Heat Sink Profiles

>> Thermal Conductivity and Alloy Choice

>> Surface Area and Fin Design

>> Mounting and Installation Options

>> Customization and Modularity

● Comparing Common Aluminum Heat Sink Profiles for LEDs

● How to Select the Best Aluminum Heat Sink Profile for Your LED Application

>> 1. Assess LED Power and Heat Output

>> 2. Consider Installation Environment

>> 3. Match Profile Size to LED Strip/Module

>> 4. Evaluate Aesthetics and Light Diffusion Needs

>> 5. Budget and Customization

● Case Studies: Profile Selection for Common LED Applications

>> A. LED Strip Lighting for Residential Use

>> B. High-Power LED Grow Lights

>> C. Architectural Accent Lighting

● The Role of Surface Treatment in Aluminum Heat Sinks

● FAQ

>> 1. What is the best aluminum alloy for LED heat sink profiles?

>> 2. How does the profile shape affect heat dissipation?

>> 3. Can I cut or customize aluminum heat sink profiles to fit my project?

>> 4. Do all LED strips require an aluminum heat sink profile?

>> 5. What is the difference between clear, frosted, and opal diffusers in LED profiles?

LED technology has revolutionized the lighting industry, offering energy efficiency, long lifespan, and design flexibility. However, one critical aspect often overlooked is thermal management. LEDs, despite their efficiency, generate heat that must be dissipated to maintain performance and longevity. Aluminum heat sink profiles play a pivotal role in this process. This comprehensive guide explores which aluminum heat sink profile is best for LEDs, examining materials, designs, applications, and selection criteria to help you make informed decisions for your lighting projects.

Why Do LEDs Need Heat Sinks?

LEDs convert most electrical energy into light, but a significant portion (about 30-40%) is still converted into heat[12]. Excessive heat can lead to:

- Reduced luminous efficacy

- Accelerated color shift

- Shortened lifespan

- Premature failure

Effective heat dissipation is therefore essential to maintain optimal LED performance and reliability[2][12].

How Do Aluminum Heat Sinks Work?

Aluminum heat sinks absorb heat from the LED and disperse it into the surrounding air. The efficiency of this process depends on several factors:

- Thermal conductivity of the material

- Surface area exposed to air

- Profile design (shape, fin arrangement)

- Installation environment (airflow, mounting method)

Material Properties

Aluminum is the most popular material for LED heat sinks due to its:

- High thermal conductivity (about 167 W/m·K, three times that of steel)[3]

- Lightweight nature, making installation easier[9]

- Corrosion resistance and ease of surface treatment (anodizing, powder coating)[3][9]

- Cost-effectiveness compared to copper or silver[6][12]

Common Aluminum Alloys Used

The most widely used alloy for LED heat sink profiles is 6063-T5 or 6060[7][10][12]. These alloys offer:

- Excellent thermal conductivity

- Good extrusion properties for complex shapes

- Superior surface finish after anodizing

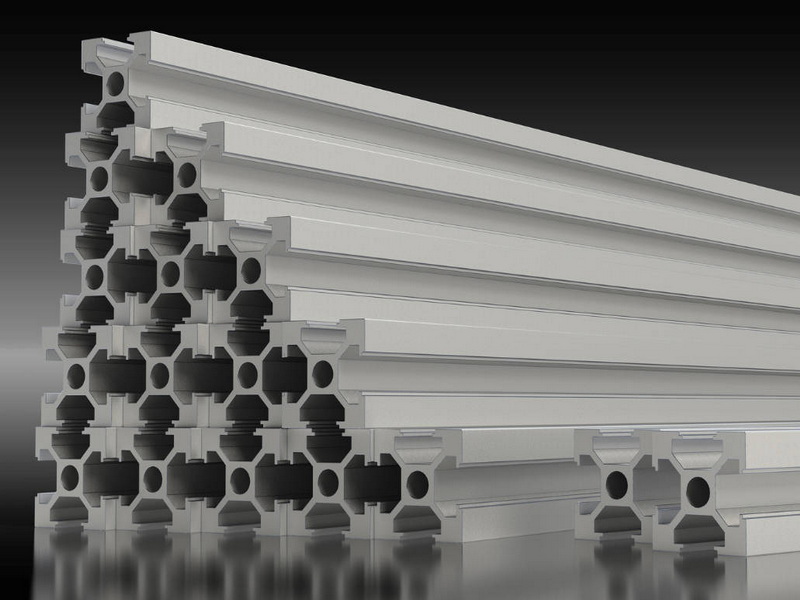

Aluminum heat sink profiles are available in various shapes and configurations to suit different LED applications. The main types include:

- Description: Simple, flat extrusions designed for surface mounting.

- Applications: Under-cabinet lighting, linear architectural accents.

- Advantages: Sleek appearance, easy installation, suitable for indirect lighting[1].

- Description: Profiles with multiple fins to maximize surface area and enhance convection.

- Applications: High-power LED modules, grow lights, industrial fixtures.

- Advantages: Superior heat dissipation, ideal for high-lumen applications[12][5].

- Description: Profiles designed for mounting in corners, typically with a 45° angle.

- Applications: Cove lighting, wall-washers, accent lighting in architectural spaces.

- Advantages: Optimizes light distribution in corners, facilitates airflow around the profile[10].

- Description: Designed to be embedded into surfaces for a flush finish.

- Applications: Ceiling, wall, or furniture integration.

- Advantages: Discreet appearance, protects LEDs from dust and impact[10].

- Description: Custom-designed shapes tailored to specific LED modules or applications.

- Applications: Specialized fixtures, OEM solutions.

- Advantages: Optimized for unique thermal and aesthetic requirements[9][12].

- 6063-T5 aluminum is widely recommended for its balance of thermal performance, extrudability, and surface finish[7][10][11][12].

- Fins increase the surface area, allowing more heat to dissipate through convection.

- The spacing and thickness of fins should allow for adequate airflow to prevent heat buildup[5][12].

- Thicker profiles can absorb and transfer more heat but may add weight and cost.

- Balance is necessary to optimize both performance and practicality.

- Profiles may be designed for surface, recessed, or corner mounting.

- Some include mounting clips, suspension cables, or adhesive guides for flexible installation[10][11].

- Many profiles include PMMA or PC diffusers to protect LEDs and diffuse light evenly[8][10][11].

- Diffuser type (clear, frosted, opal) affects both light output and heat dissipation.

- Custom extrusions allow for precise matching of thermal requirements and fixture aesthetics[9][12].

- Modular profiles can be cut to length and adapted for various projects[4][7].

Profile Type | Best For | Heat Dissipation | Aesthetics | Installation | Cost |

Flat Profile | Low-power, linear | Moderate | Sleek | Easy | Low |

Finned Profile | High-power, industrial | Excellent | Functional | Moderate | Moderate |

Corner/Angular | Accent, corners | Good | Stylish | Moderate | Moderate |

Recessed/Flush-Mount | Integrated, hidden | Good | Discreet | Complex | Moderate |

Custom Extruded | Specialized needs | Optimized | Custom | Variable | Variable |

- Higher power LEDs require profiles with greater surface area and more efficient heat dissipation[3][12].

- Indoor vs. outdoor: Outdoor profiles need better corrosion resistance and weatherproofing[4].

- Mounting type: Surface, recessed, or corner mounting will dictate profile shape[10].

- The profile must accommodate the width and thickness of the LED strip or module[7][10].

- Choose profiles with suitable diffusers for the desired light output and appearance[4][8].

- Standard profiles are cost-effective for most applications.

- Custom profiles are justified for high-performance or unique design requirements[9][12].

- Recommended Profile: Flat or recessed aluminum profile with a frosted diffuser.

- Why: Sufficient for low to moderate power, provides a clean look, and protects LEDs from dust[1][4].

- Recommended Profile: Large finned extruded aluminum profile.

- Why: Maximizes heat dissipation for high-power modules, ensuring LED longevity[5][12].

- Recommended Profile: Corner or angular profile with opal diffuser.

- Why: Enhances light distribution in corners, adds design flair, and offers good thermal management[10].

- Recommended Profile: Anodized aluminum profile with weather-resistant finish.

- Why: Superior corrosion resistance and durability in harsh environments[4].

Surface treatments such as anodizing, powder coating, and electroplating not only enhance corrosion resistance but can also improve heat dissipation by increasing emissivity[3][9]. Anodized finishes are particularly popular for their durability and aesthetic appeal.

Selecting the best aluminum heat sink profile for LEDs involves balancing thermal performance, aesthetics, installation requirements, and budget. For most applications, extruded 6063-T5 aluminum profiles with appropriate surface area and fin design offer the best combination of heat dissipation, durability, and cost-effectiveness. Finned profiles excel in high-power or industrial settings, while flat and corner profiles are ideal for residential and architectural lighting.

Always match the profile to your specific LED module's power and installation environment, and consider surface treatments for added protection and improved performance. By investing in the right aluminum heat sink profile, you ensure your LED lighting system remains efficient, reliable, and visually appealing for years to come.

The most widely used and recommended alloy is 6063-T5 aluminum, valued for its high thermal conductivity, ease of extrusion, and excellent finish after anodizing[7][10][12].

Profile shape determines the surface area exposed to air, which is critical for heat dissipation. Finned profiles maximize surface area and airflow, making them ideal for high-power LEDs, while flat profiles are suitable for lower-power applications[5][12].

Yes, most aluminum profiles can be cut to length with proper tools, and many suppliers offer custom extrusion services for specialized applications[4][7][12].

While not all LED strips need a heat sink, it is strongly advised for medium to high-power strips or installations running for long periods, as proper heat sinking ensures optimal performance and longevity[6][12].

Clear diffusers allow maximum light output with minimal diffusion, frosted diffusers balance light output and diffusion, and opal diffusers provide the softest, most diffused light but with slightly reduced brightness[4][8].

[1] https://www.leds.shop/collections/aluminium-profiles-heat-sinks

[2] https://www.sindathermal.com/info/how-to-choose-a-heat-sink-for-led-90162191.html

[3] https://www.zpheatsink.com/info/material-selection-for-led-heat-sink-77070364.html

[4] https://www.topledprofile.com/blog/faq-of-led-profiles-b84dcc9a-a8ed-471b-a7a6-442326916b3c

[5] https://www.mars-hydro.com/info/post/heat-sink-an-essential-detail-that-determines-the-quality-of-led-grow-lights

[6] https://marcled.com/blog/2023/08/25/do-led-strip-lights-need-a-heat-sink/

[7] https://www.richelieu.com/ca/en/category/lighting-solutions-and-accessories/led-lighting-and-profiles/led-profiles-and-accessories/led-profiles/cool-profile-heat-sink-for-led-tape-lights/1196909/sku-30145000

[8] https://aidiwattlighting.com/led-aluminum-profiles-the-ultimate-buying-guide/

[9] https://www.shenghai-alu.com/article/why-does-led-choose-extruded-aluminium-heatsink.44

[10] https://www.linkedin.com/pulse/comprehensive-guide-using-aluminum-profiles-led-strips-mylikeled-5a8lc

[11] https://www.ledyilighting.com/ultimate-guide-to-aluminum-profile-for-led-strip/

[12] https://www.fonnovaluminium.com/led-light-profile

[13] https://kingornan.com/led-aluminium-profile-guide-2022/

[14] https://www.reddit.com/r/hydro/comments/1dzehv6/what_kind_of_aluminium_as_heat_sink_for_diy_led/

[15] https://www.superlightingled.com/hlbapl035-height-21mm-ceiling-recessed-extruded-aluminum-channel-profile-good-heatsink-for-width-16mm-led-ribbon-lights-p-1711.html

[16] https://www.chaluminium.com/aluminium-heat-sink-for-led-strip

[17] https://www.ledsupply.com/led-heatsinks

[18] https://www.gabrian.com/6-heat-sink-types/

[19] https://www.heatell.com/choosing-the-right-heat-sink-for-your-application/

[20] https://thelightingoutlet.com.au/collections/led-heat-sink

[21] https://www.global.dnp/biz/column/detail/10162228_4117.html

[22] https://kimsen.vn/extrusion-aluminum-vs-die-cast-heat-sink-ne90.html

[23] https://www.reddit.com/r/WLED/comments/zzjilv/will_bare_aluminum_sheet_strips_be_good_enough_as/

[24] https://www.qats.com/Product/Heat-Sinks/LED-Cooling-/LED-Heat-SinkRound-Star-Shape/ATSEU-110-C1-R0/2539.aspx

[25] https://lumileds.com/wp-content/uploads/files/AB23.pdf

[26] https://www.vst-lighting.com/solution-to-led-strip-heat-issues/

[27] https://www.kingkatech.com/is-aluminum-a-suitable-metal-for-an-led-heatsink.html

[28] https://www.shine.lighting/threads/led-heat-sinks.11/

[29] https://www.linkedin.com/pulse/led-heat-sink-what-why-its-important-martin-wan-7fthc

[30] https://www.niuyuantrims.com/led-profiles-guide/

[31] https://californialightworks.com/blog/led-heat-sinks-what-are-they-and-how-do-they-affect-grow-light-performance/

[32] https://www.ledyilighting.com/led-heat-sink/

[33] https://www.waveformlighting.com/knowledgebase/lighting-products/do-your-led-strip-lights-require-heat-sinks

[34] https://thelightingoutlet.com.au/blogs/news/led-profiles-accessories-guide

[35] https://www.reef2reef.com/threads/led-heatsink-question.722631/

[36] https://www.kenfatech.com/faqs-for-heat-sinks/

[37] https://frigate.ai/product/led-lighting-heat-sinks/

[38] https://aluminium-profiles-italy.eu/dissipatori-di-calore.htm

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden