English

Views: 222 Author: Astin Publish Time: 2025-03-15 Origin: Site

Content Menu

● Introduction to Aluminum Extrusion Profiles

>> Types of Aluminum Extrusion Profiles

● Applications of Aluminum Extrusion Profiles

● Factors Contributing to the Popularity of Aluminum Extrusion Profiles

● Stock Aluminum Extrusion Profiles

● Market Trends and Future Outlook

● FAQs

>> 1. What are the most common aluminum alloys used for extrusion profiles?

>> 2. What are the advantages of using stock aluminum extrusion profiles?

>> 3. How is the aluminum extrusion process carried out?

>> 4. What are some common applications of aluminum extrusion profiles?

>> 5. What factors are driving the growth of the aluminum extrusion market?

Aluminum extrusion profiles have become a cornerstone in various industries, including construction, automotive, and consumer goods, due to their versatility, durability, and lightweight properties. In 2025, the demand for these profiles continues to rise, driven by advancements in technology and increasing applications across different sectors. This article will delve into the most popular aluminum extrusion profiles, their applications, and the factors contributing to their popularity.

Aluminum extrusion is a process where aluminum alloy is forced through a die to create a specific cross-sectional shape. This process allows for the creation of complex profiles with high precision and consistency. The resulting profiles can be used in a wide range of applications, from structural components in buildings to decorative elements in furniture.

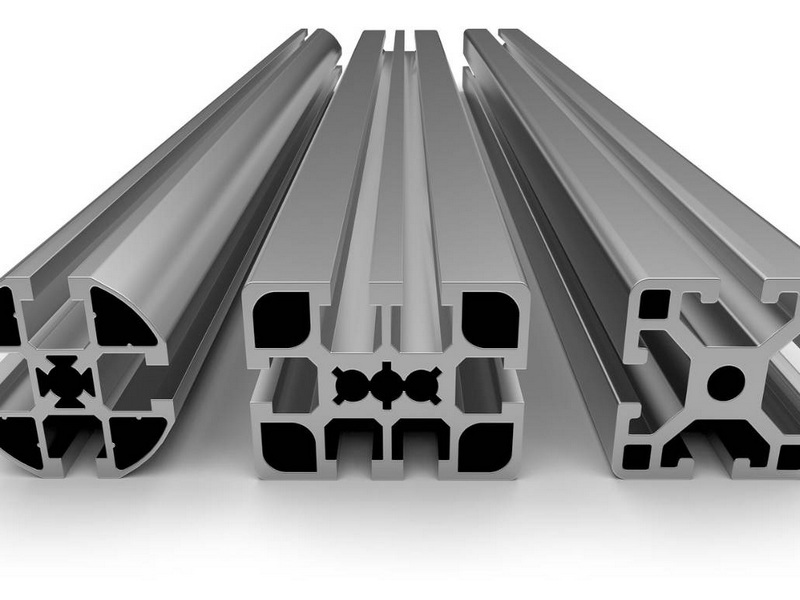

1. Solid Shapes: These include squares, rectangles, circles, and custom shapes. Solid extrusions are known for their strength and simplicity, making them ideal for applications requiring high structural integrity.

2. Hollow Shapes: Tubes, pipes, and custom profiles with voids are common examples. Hollow extrusions offer a balance between weight reduction and structural integrity, making them suitable for applications where both are crucial.

3. Semi-Hollow Shapes: These provide a middle ground between solid and hollow shapes, offering a balance of strength, weight, and cost. They are often used in applications that require structural robustness while benefiting from weight reduction.

4. Standard Profiles: These include L-angled, square, solid round tubes, hollow tubes, T-shaped bars, J caps, Z clips, dividers, channels, sliding track systems, framing systems, wheels, gaskets, door locks, and more. Standard profiles are widely available as stock aluminum extrusion profiles, which can be easily sourced from suppliers without the need for custom tooling.

5. Custom Profiles: These are designed to meet specific customer requirements and can be tailored for unique applications. While they require custom tooling, they offer flexibility in design and functionality.

Aluminum extrusion profiles are used across various industries due to their versatility and benefits:

- Construction: Aluminum profiles are widely used in building frames, doors, windows, and decorative elements due to their corrosion resistance and strength-to-weight ratio.

- Automotive: They are used in vehicle frames, engine components, and body parts to reduce weight while maintaining structural integrity.

- Furniture and Interior Design: Aluminum extrusions are used in making frames for chairs, tables, and other furniture pieces, as well as decorative elements like railings and partitions.

- Electronics and Packaging: Aluminum profiles are used in electronic enclosures, heat sinks, and packaging materials due to their thermal conductivity and durability.

- Aerospace: In the aerospace industry, aluminum extrusions are used for structural components due to their high strength-to-weight ratio and resistance to corrosion.

Several factors contribute to the increasing demand for aluminum extrusion profiles:

1. Lightweight and Corrosion Resistance: Aluminum is significantly lighter than steel while offering good corrosion resistance, making it ideal for applications where weight reduction is crucial.

2. Versatility in Design: The extrusion process allows for complex shapes to be produced with high precision, enabling designers to create innovative and functional products.

3. Cost-Effectiveness: Compared to other metals, aluminum extrusions can be more cost-effective, especially when considering the long-term benefits of reduced maintenance and energy efficiency.

4. Sustainability: Aluminum is recyclable, which aligns with modern sustainability goals and reduces environmental impact.

5. Technological Advancements: Improvements in extrusion technology have made it possible to produce profiles with higher precision and consistency, further enhancing their appeal.

Stock aluminum extrusion profiles are pre-manufactured profiles available for immediate purchase without the need for custom tooling. These profiles are beneficial for projects with tight deadlines or those requiring standard shapes. Suppliers like Wellste offer a wide range of standard profiles, including aluminum angles, channels, flat bars, I beams, T bars, and framing systems. These profiles are typically made from 6063 and 6061 aluminum alloys, which are suitable for architectural and structural applications, respectively.

The use of stock aluminum extrusion profiles simplifies the procurement process, allowing businesses to quickly meet their project needs without the long lead times associated with custom orders. This efficiency is particularly valuable in industries where project timelines are tight and delays can be costly.

The aluminum extrusion market is expected to grow significantly over the next few years, driven by increasing demand in construction, automotive, and packaging sectors. The integration of technology, such as artificial intelligence, and strategic collaborations are expected to further enhance production efficiency and product innovation. As urbanization increases globally, the need for lightweight, durable materials in construction and infrastructure projects will continue to drive the demand for aluminum extrusion profiles.

Moreover, the trend towards sustainable and eco-friendly materials is also influencing the market. Aluminum's recyclability and energy efficiency make it an attractive choice for companies aiming to reduce their environmental footprint. This shift towards sustainability is likely to continue, further boosting the demand for aluminum extrusions.

Aluminum extrusion profiles are a vital component in many industries due to their versatility, durability, and cost-effectiveness. The availability of stock aluminum extrusion profiles simplifies the procurement process for standard shapes, allowing businesses to quickly meet their project needs. As the market continues to grow, driven by technological advancements and increasing demand, aluminum extrusion profiles will remain a cornerstone in modern manufacturing.

The most common aluminum alloys used for extrusion profiles are 6063 and 6061. The 6063 alloy is typically used for architectural applications due to its excellent corrosion resistance and surface finish, while the 6061 alloy is used for structural applications due to its high strength and durability.

Stock aluminum extrusion profiles offer several advantages, including reduced lead times, lower costs (as no custom tooling is required), and immediate availability. This makes them ideal for projects with tight deadlines or those requiring standard shapes.

The aluminum extrusion process involves heating an aluminum billet to a malleable state, then forcing it through a die under high pressure to achieve the desired shape. The extruded profile is then cooled, cut to length, and finished with various surface treatments.

Aluminum extrusion profiles are used in construction for building frames and decorative elements, in the automotive sector for vehicle parts, in furniture for frames and decorative pieces, and in electronics for enclosures and heat sinks.

The growth of the aluminum extrusion market is driven by factors such as increasing demand in construction and automotive sectors, governmental support, technological advancements, and the trend towards sustainable and lightweight materials.

[1] https://www.alibaba.com/showroom/2025-aluminum-extrusion.html

[2] https://blog.tbrc.info/2025/03/aluminum-extrusion-industry/

[3] https://www.wellste.com/standard-aluminum-extrusion-profiles/

[4] https://www.zetwerk.com/aluminum-extrusions/

[5] https://ensun.io/search/aluminium-extrusion

[6] https://yxytbuilding.en.made-in-china.com/product-group/YeZtMQSPhgpo/Aluminium-Profile-Aluminium-Extrusion-catalog-1.html

[7] https://www.lightmetalage.com/news/industry-news/extrusion/aec-issues-call-for-entries-for-2025-aluminum-extrusion-design-competition/

[8] https://www.researchandmarkets.com/reports/5685568/2025-aluminium-extrusion-market-outlook-report

[9] https://shreliance.en.made-in-china.com/product/doiESNAbXplJ/China-2025-Hot-Sale-High-Strength-Customized-Design-Aluminium-Extrusion-Profile-for-Building-Material.html

[10] https://www.industryarc.com/Research/Aluminium-Profiles-And-Fittings-Market-Research-5031971

[11] https://www.chiefdelphi.com/t/most-commonly-used-aluminum-extrusion-profiles/137785

[12] https://jma-aluminum.com

[13] https://www.giiresearch.com/report/tbrc1672271-aluminum-extrusion-global-market-report.html

[14] https://www.researchandmarkets.com/reports/5685580/2025-aluminum-extrusion-market-outlook-report

[15] https://texastechnology.us/aluminum-extrusion-profiles/

[16] https://haluminium.com/hoonly-aluminium-extrusion-profile-faq/

[17] https://us.metoree.com/categories/100086/

[18] https://www.cognitivemarketresearch.com/extruded-aluminum-profiles-market-report

[19] https://www.thebusinessresearchcompany.com/report/aluminum-extrusion-global-market-report

[20] https://proax.ca/en/category/5308/aluminum-extrusions

[21] https://extrude-a-trim.com/in-stock-shapes/

[22] https://www.profall.com/en/standard-aluminum-extrusion-profiles

[23] https://www.shengxinglobal.com/blog/aluminum-extrusion-profiles-the-definitive-guide-2025.html

[24] https://tri-stateal.com/products/standard-extrusions/

[25] https://www.gdcalm.com/some-questions-about-aluminum-extrusion.html

[26] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[27] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[28] https://bitfab.parts/blog/what-are-the-sizes-of-aluminum-extrusion-profiles/

[29] https://aec.org/faqs

[30] https://www.fjxxaluminum.com/blog/frequently-asked-questions-about-aluminium-extrusion:-your-comprehensive-guide/

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden

Top Aluminum Furnitures Manufacturers and Suppliers in Switzerland

Top Aluminum Furnitures Manufacturers and Suppliers in Netherlands

Top Aluminum Furnitures Manufacturers and Suppliers in France

Top Aluminum Furnitures Manufacturers and Suppliers in Spain

Top Aluminum Furnitures Manufacturers and Suppliers in Italy

Top Aluminum Furnitures Manufacturers and Suppliers in Germany