English

Views: 222 Author: Astin Publish Time: 2025-04-29 Origin: Site

Content Menu

● Understanding Aluminum Glass Frame Profiles

● Types of Aluminum Glass Frame Profiles

● Key Features of the Best Aluminum Glass Frame Profiles

>> Security

● Popular Aluminum Glass Frame Profiles for Modern Windows

● Manufacturing Process of Aluminum Frame Profiles

>> Extrusion

>> Tempering

● Advantages of Aluminum Glass Frame Profiles in Modern Windows

>> Environmental Sustainability

● How to Choose the Best Aluminum Glass Frame Profile for Your Project

● Common Applications of Aluminum Glass Frame Profiles

● Innovations in Aluminum Glass Frame Profiles

● Challenges and Considerations

● FAQ

>> 1. What are the main types of aluminum glass frame profiles used in modern windows?

>> 2. How do aluminum frames compare to other materials like wood or PVC?

>> 3. What is a thermal break, and why is it important in aluminum window profiles?

>> 4. Can aluminum window profiles be customized for unique architectural designs?

>> 5. How long do aluminum glass frame profiles typically last?

Modern architecture continuously seeks the perfect balance between aesthetics, functionality, and sustainability. One of the most critical components in achieving this harmony is the window system, particularly the frame profile that supports the glass. Aluminum glass frame profiles have become the gold standard for contemporary windows, offering a blend of strength, minimalism, and adaptability. This comprehensive guide explores the best aluminum glass frame profiles for modern windows, examining their types, benefits, manufacturing processes, and how to select the ideal profile for your project.

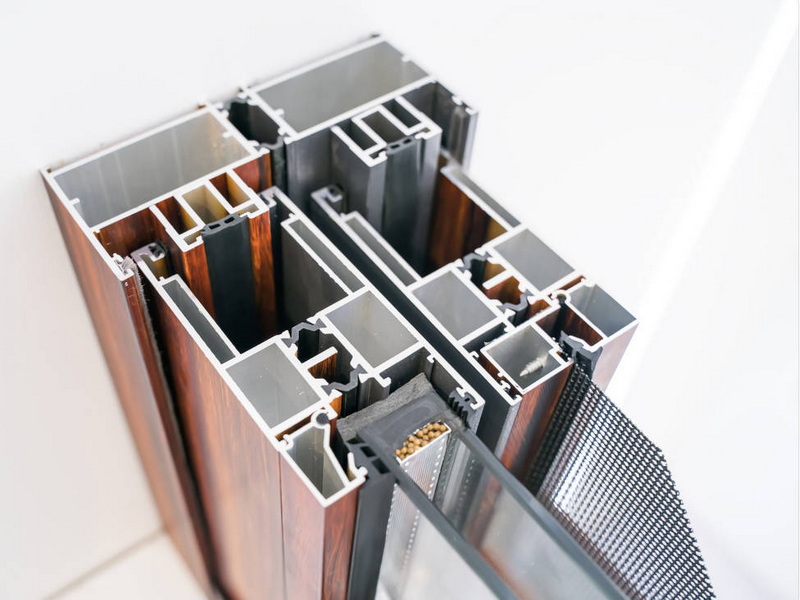

Aluminum glass frame profiles are extruded sections of aluminum designed to hold and support glass panes in window systems. Unlike traditional materials such as wood or steel, aluminum provides a unique combination of lightweight structure, durability, and design flexibility, making it the preferred choice for modern buildings.

- Strength and Durability: Aluminum frames withstand harsh weather, resist corrosion, and maintain their structural integrity over decades.

- Lightweight: Easier to handle and install, especially for large or complex glazing systems.

- Design Versatility: Can be extruded into a wide range of shapes and sizes, accommodating everything from minimalist facades to intricate architectural statements.

- Slim Sightlines: Allow for larger glass areas and more natural light, a hallmark of contemporary design.

- Low Maintenance: Requires minimal upkeep compared to wood, with finishes like powder coating or anodizing further enhancing longevity.

Modern window systems utilize a variety of aluminum frame profiles, each tailored to specific functional and aesthetic requirements. Understanding the main types helps in selecting the right profile for your project.

Square profiles feature equal sides and sharp corners, presenting a clean, streamlined look. Their linear simplicity suits minimalist and industrial designs, maximizing the glass area for unobstructed views.

Rectangular profiles offer versatility in width and height, making them suitable for different window types such as casement, sliding, or fixed windows. They are commonly used in commercial buildings where expansive views are desired.

Channel profiles, often U-shaped, serve as tracks for sliding windows or as reinforcement elements. Their groove shapes efficiently accommodate moving parts and add structural integrity, especially in heavy or multi-pane systems.

T-slot profiles include a T-shaped slot along the length, enabling easy attachment of accessories or components. This modularity is ideal for systems requiring future adjustments or upgrades.

Aluminum's malleability allows for custom profiles tailored to unique architectural visions. Whether you need curved, angled, or hybrid shapes, modern extrusion techniques can deliver the required precision.

When evaluating aluminum glass frame profiles for modern windows, several features distinguish the best options from standard offerings.

Modern aesthetics favor minimal framing and maximal glass exposure. The best profiles offer ultra-slim sightlines, sometimes as narrow as 51mm, ensuring unobstructed views and abundant daylight

Advanced profiles incorporate thermal breaks-non-metallic barriers within the frame-to reduce heat transfer and improve energy efficiency. This is crucial for meeting modern building codes and enhancing comfort.

High-quality aluminum frames support robust locking systems and are often tested to stringent security standards, including resistance to forced entry.

Powder coating and anodizing allow for a vast range of colors and finishes, ensuring compatibility with any design scheme while providing extra protection against the elements.

Profiles can be tailored in terms of thickness, shape, and size, accommodating everything from oversized picture windows to intricate geometric installations.

Several profiles have gained prominence in the market due to their superior performance and design flexibility.

Flush casement profiles create a seamless look where the opening vent sits flush with the outer frame. This design is increasingly popular for its clean lines and modern appeal.

Sliding window systems rely on channel or track profiles that facilitate smooth operation and support large glass panels. These profiles are engineered for stability and ease of movement.

Tilt-and-turn profiles allow windows to open in multiple ways, enhancing ventilation and access. They require precise engineering to ensure airtightness and security while maintaining slim sightlines.

For large, floor-to-ceiling glazing, robust yet slim profiles are essential. These are typically reinforced and engineered to support heavier glass loads without compromising aesthetics.

The creation of aluminum window profiles is a sophisticated process that ensures each profile meets strict standards for strength, precision, and finish.

Extrusion is the primary manufacturing technique. A heated aluminum billet is forced through a steel die, forming the desired profile shape. This process allows for intricate cross-sections and consistent quality.

Most high-quality profiles use 6000 series aluminum alloys, particularly 6063, known for its excellent surface finish and corrosion resistance.

Profiles are tempered (T3-T8) to achieve the required hardness and mechanical properties, ensuring durability and resistance to deformation.

Finishes such as powder coating or anodizing enhance the profile's appearance and protect against corrosion, UV exposure, and wear.

Each profile undergoes rigorous inspection for dimensional accuracy, surface quality, and mechanical properties before being shipped for fabrication or installation.

Aluminum frame profiles offer a host of benefits that make them the preferred choice for contemporary window systems.

Aluminum frames can last 25 to 50 years or more with minimal maintenance, outlasting many alternative materials.

The ability to extrude aluminum into virtually any shape allows architects to realize bold visions, from sweeping curves to razor-thin mullions.

Aluminum is highly recyclable, and many manufacturers use recycled content in their profiles, reducing the environmental footprint of new windows.

Anodized or powder-coated aluminum resists corrosion, fading, and warping, even in extreme climates. This makes it suitable for coastal, urban, and high-altitude locations.

Aluminum's inherent strength, combined with advanced locking systems, provides excellent security for residential and commercial buildings.

Unlike wood, aluminum does not rot, warp, or require frequent painting. Occasional cleaning is typically sufficient to maintain its appearance.

Selecting the right profile involves balancing several factors:

- Aesthetic Preferences: Consider the desired sightlines, frame color, and overall style.

- Performance Requirements: Evaluate thermal insulation, security features, and acoustic performance.

- Window Type: Match the profile to the window operation-casement, sliding, tilt-and-turn, or fixed.

- Glazing Size and Weight: Ensure the profile can support the intended glass dimensions and weight.

- Budget: Premium profiles offer advanced features but may come at a higher cost.

- Local Climate: Opt for profiles with enhanced weather resistance in harsh environments.

Consulting with manufacturers or window specialists can help identify the best profile for your specific needs.

Aluminum profiles are used in a wide range of modern window applications, including:

- Residential Homes: From urban apartments to luxury villas, aluminum frames provide sleek aesthetics and robust performance.

- Commercial Buildings: Office towers, retail spaces, and hotels benefit from the durability and design flexibility of aluminum profiles.

- Curtain Walls: Large glass facades rely on custom aluminum profiles for structural support and minimal visual obstruction.

- Renovations: Aluminum frames are ideal for upgrading older buildings to meet modern performance and design standards.

The industry continues to evolve, with new technologies enhancing the performance and aesthetics of aluminum window frames.

Modern profiles often feature advanced thermal break technology, using polyamide or other insulating materials to minimize heat transfer and improve energy efficiency.

Profiles now accommodate integrated blinds, trickle vents, and advanced locking systems, streamlining installation and enhancing functionality.

Manufacturers are increasingly adopting eco-friendly practices, such as using recycled aluminum and low-emission finishes, to reduce environmental impact.

While aluminum profiles offer many advantages, there are some considerations to keep in mind:

- Thermal Conductivity: Aluminum conducts heat, so profiles without thermal breaks can lead to energy loss. Always opt for thermally broken profiles in climates with temperature extremes.

- Initial Cost: High-quality aluminum frames can be more expensive than some alternatives, though their longevity and low maintenance often offset this over time.

- Condensation: Poorly designed frames may be prone to condensation in certain climates. Proper installation and ventilation mitigate this risk.

Aluminum glass frame profiles have become the benchmark for modern windows, offering unmatched strength, design flexibility, and longevity. The best profiles combine slimline aesthetics, advanced thermal performance, robust security, and a wide range of finishes to suit any architectural vision. Whether you are designing a minimalist home, a commercial tower, or a unique renovation, choosing the right aluminum frame profile is essential for achieving both beauty and performance. By understanding the types, features, and manufacturing processes of these profiles, you can make an informed decision that enhances your building's value and appeal for decades to come.

The main types include square, rectangular, channel, and T-slot profiles, each offering unique benefits for different window designs. Custom profiles are also available for specialized architectural requirements.

Aluminum frames are more durable, lightweight, and resistant to weathering than wood or PVC. They offer slimmer sightlines and require less maintenance, making them ideal for modern architecture.

A thermal break is a non-metallic barrier within the frame that reduces heat transfer, improving energy efficiency and indoor comfort. It is essential for meeting modern building codes and achieving high thermal performance.

Yes, aluminum's malleability allows for custom profiles in various shapes, sizes, and finishes, enabling architects to realize bespoke designs and meet specific project requirements.

With proper care, high-quality aluminum window profiles can last 25 to 50 years or more, maintaining their structural integrity and appearance throughout their lifespan.

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden