English

Views: 222 Author: Astin Publish Time: 2025-05-07 Origin: Site

Content Menu

● Understanding Aluminum Light Box Profiles

● Types of Aluminum Light Box Profiles

>> 1. Fabric Light Box Profiles

>> 2. Frameless Fabric LED Light Box Profiles

>> 3. Ultra Slim Light Box Profiles

>> 4. Indicated Light Box Profiles

>> 5. LED Display Aluminum Frames

● Advantages of Aluminum Light Box Profiles

● How Are Aluminum Light Box Profiles Used?

>> Installation Process Overview

● FAQ

>> 1. What materials are aluminum light box profiles made from?

>> 2. Can aluminum light box profiles be used outdoors?

>> 3. How are aluminum light box profiles installed?

>> 4. What types of light boxes can be made with aluminum profiles?

>> 5. How do aluminum light box profiles improve LED strip lifespan?

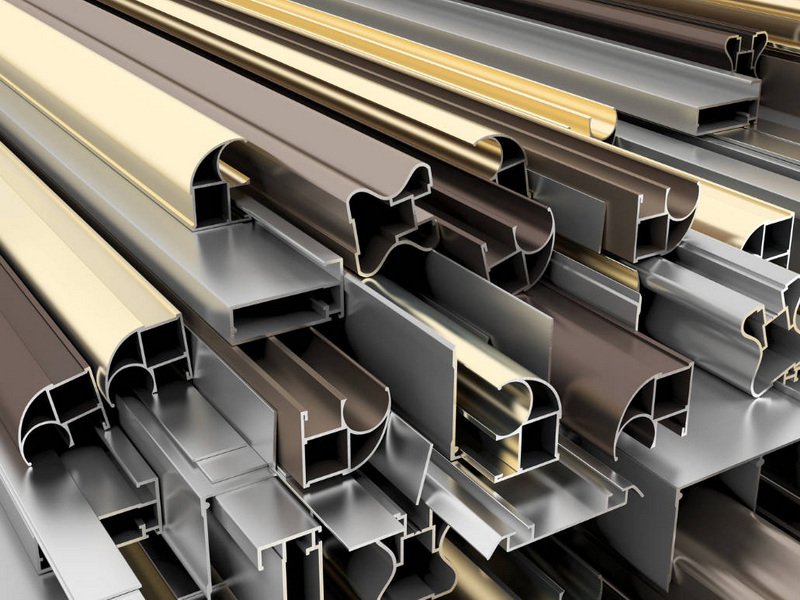

Aluminum light box profiles are specialized aluminum extrusions designed primarily for constructing light boxes used in advertising and display applications. These profiles serve as the structural framework that holds light sources, such as LED strips, and display materials like fabric, acrylic, or printed films. Their unique properties and versatile designs make them an essential component in modern illuminated signage and advertising displays.

An aluminum light box profile is a frame made from high-quality aluminum alloys, extruded into specific shapes and sizes to support light boxes. These profiles are designed to be durable, lightweight, and corrosion-resistant, making them suitable for both indoor and outdoor use. They often come with surface treatments such as anodizing, electrophoresis, or fluorocarbon spraying to enhance appearance and longevity.

- Material: Typically made from 1000 to 7000 series aluminum alloys, offering excellent strength and corrosion resistance.

- Surface Finish: Available in various colors and finishes including sand white, sand black, silver anodized, and gold.

- Dimensions: Profiles come in various widths and thicknesses, ranging from ultra-slim 2.5 mm walls to thicker 2.5 mm or more for outdoor durability.

- Customization: Can be bent or shaped into various forms such as square, round, or oval to fit specific design needs.

There are several main types of aluminum light box profiles, each suited for different applications and design requirements:

These profiles are designed to hold fabric graphics stretched over the frame. They typically feature rounded or profiled edges and come in wall thicknesses from 0.5 mm to 2.0 mm. They are popular for retail stores, mobile shops, and supermarkets due to their sleek appearance and easy installation.

These aluminum profiles allow the frame to open on all four sides for easy graphic changes. With wall thicknesses between 1.5 mm and 2.5 mm, they are ideal for outdoor advertising where wind resistance and corrosion protection are critical.

Ultra slim profiles have thin walls (1 mm to 1.5 mm) and are designed for minimal visual impact. They are used for single-sided or double-sided light boxes, often in restaurants or small retail shops where space is limited.

These are specialized profiles used for directional signage in places like subways, airports, and parking garages. They are customized to meet specific site requirements and provide clear guidance to visitors.

These profiles are designed to house LED electronic strips and displays, offering both curved and straight options with widths around 9 cm. They provide excellent heat dissipation and structural support for LED modules.

- Durability: Aluminum is corrosion-resistant and maintains its appearance over time, even in outdoor environments.

- Lightweight: Easier to install and handle compared to heavier materials like steel.

- Heat Dissipation: Aluminum effectively dissipates heat from LED strips, extending their lifespan.

- Aesthetic Appeal: Available in multiple finishes and colors, aluminum profiles provide a clean, professional look.

- Customization: Profiles can be bent or cut to custom sizes and shapes, accommodating various design needs.

- Easy Installation: Profiles often come with accessories like corner connectors, mounting brackets, and silicone strips for quick assembly.

Aluminum light box profiles are used as the framework for illuminated advertising displays in various settings:

- Retail Stores: For eye-catching promotional displays and branding.

- Public Spaces: Airports, train stations, and subways use light boxes for signage and wayfinding.

- Exhibitions and Trade Shows: Portable and durable light boxes for dynamic presentations.

- Outdoor Advertising: Billboards and street-side signs benefit from aluminum's weather resistance.

- Interior Design: Ambient lighting and decorative panels in commercial and residential spaces.

1. Planning and Measurement: Determine the size and shape of the light box and select the appropriate aluminum profile.

2. Cutting and Shaping: Profiles are cut to length and bent if necessary using specialized machines.

3. Assembly: Frames are assembled using corner connectors and screws.

4. Lighting Installation: LED strips are mounted inside the profile, often with diffusers to soften the light.

5. Graphic Installation: Fabric, acrylic, or printed films are attached to the frame.

6. Mounting: The completed light box is installed on walls, ceilings, or stands.

Aluminum light box profiles require minimal maintenance. Regular cleaning with a soft cloth and mild detergent keeps them looking new. Their corrosion resistance means they do not rust, and they withstand harsh weather conditions without degradation. Proper sealing and waterproofing ensure the internal lighting components remain protected.

Aluminum light box profiles are integral to the construction of modern illuminated advertising and display solutions. Their combination of durability, lightweight design, aesthetic versatility, and ease of installation makes them the preferred choice for indoor and outdoor light boxes. Whether used in retail, public infrastructure, or exhibitions, aluminum profiles provide a reliable framework that enhances the visual impact and lifespan of light boxes.

They are made from high-grade aluminum alloys, typically ranging from 1000 to 7000 series, offering strength, corrosion resistance, and good heat dissipation.

Yes, aluminum profiles are corrosion-resistant and suitable for outdoor use, especially when treated with protective coatings and paired with waterproof LED strips.

Profiles are cut to size, assembled with connectors, LED strips are installed inside, diffusers are added, and the entire light box is mounted using brackets or screws.

Types include fabric light boxes, frameless fabric LED light boxes, ultra-slim light boxes, indicated light boxes for signage, and LED display frames.

Aluminum acts as a heat sink, dissipating heat generated by LEDs, which prevents overheating and extends the operational life of the LED strips.

Top Aluminum Windows Manufacturers and Suppliers in Saudi Arabia

Top Aluminum Windows Manufacturers and Suppliers in Indonesia

Top Aluminum Windows Manufacturers and Suppliers in Malaysia

Common alloy series and performance analysis of aluminum profiles

Top Aluminum Windows Manufacturers and Suppliers in Thailand

Top Aluminum Windows Manufacturers and Suppliers in Singapore