English

Views: 222 Author: Astin Publish Time: 2025-04-21 Origin: Site

Content Menu

● Introduction to Aluminum Extrusion Profiles

● The Global Aluminum Extrusion Market in 2025

● Guangdong Weiye Group: Leading the Way in Aluminum Extrusion

>> Technological Innovation and R&D

>> Product Portfolio and Applications

>> Sustainability and Social Responsibility

>> Global Influence and Strategic Vision

● Other Top Aluminum Extrusion Profile Manufacturers in 2025

>> Hindalco Industries Ltd. (Novelis)

>> Bonnell Aluminum (Tredegar Corp.)

>> QALEX

● Key Industry Trends and Innovations in 2025

>> 1. Lightweighting and Electric Vehicles

>> 2. Expansion in Construction

>> 3. Technological Advancements

>> 4. Sustainability and Green Manufacturing

>> 5. Customization and Value-Added Services

● Frequently Asked Questions (FAQ)

>> 1. What makes Guangdong Weiye Group a top aluminum extrusion profile manufacturer in 2025?

>> 2. What are the main applications of aluminum extrusion profiles in 2025?

>> 3. How are manufacturers improving quality control in aluminum extrusion?

>> 4. What sustainability practices are common among leading aluminum extrusion manufacturers?

>> 5. How do I choose the right aluminum extrusion supplier for my project?

Aluminum extrusion profiles are the backbone of modern industry, enabling innovation in construction, transportation, electronics, and countless other sectors. As global demand for lightweight, durable, and sustainable materials continues to surge, the aluminum extrusion industry stands at the forefront of technological advancement and market growth. In 2025, a select group of manufacturers are setting new standards for quality, innovation, and global reach. This article provides a comprehensive exploration of the top aluminum extrusion profile manufacturers in 2025, with a special focus on Guangdong Weiye Group, a leader in the field. We will also examine market trends, technological innovations, and answer key questions shaping the future of aluminum extrusion.

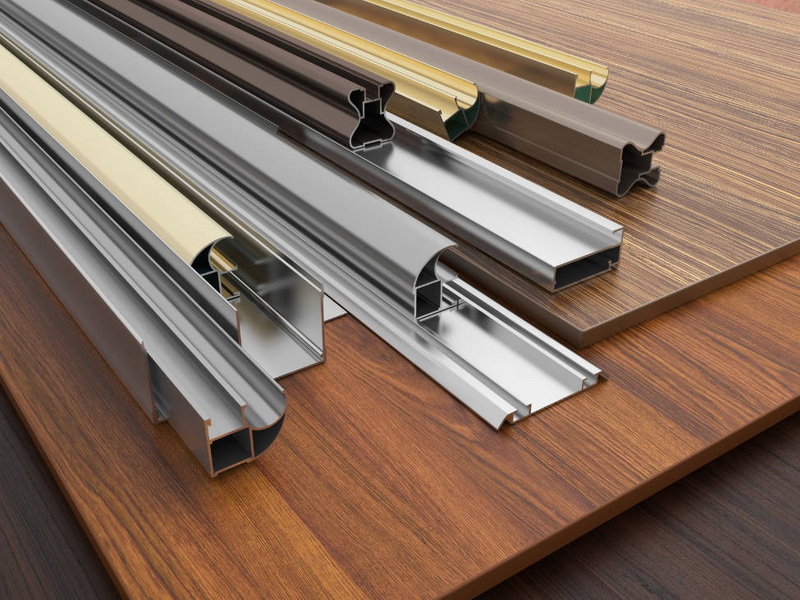

Aluminum extrusion is a process that shapes aluminum alloy into objects with a defined cross-sectional profile. This method leverages aluminum's unique properties—lightweight, high strength-to-weight ratio, corrosion resistance, and recyclability—making it ideal for a wide range of applications. From architectural frameworks and vehicle chassis to solar panel mounts and consumer electronics, extruded aluminum profiles are integral to modern engineering and design[11].

The global aluminum extrusion market is experiencing robust growth, projected to reach $25 billion in 2025 and expand at a CAGR of 6% through 2033[6]. This expansion is driven by:

- The construction industry's demand for sustainable and durable materials.

- The automotive sector's pursuit of lightweight components for electric and fuel-efficient vehicles.

- The rise of renewable energy applications, such as solar panel frames.

- Technological advancements, including the integration of artificial intelligence and automation in manufacturing[8][9].

Asia-Pacific, particularly China, is leading this growth, with North America and Europe maintaining significant market shares[6][9].

Established in 1992 and headquartered in Nanhai, Guangdong Province, Guangdong Weiye Group has evolved into a large-scale, comprehensive aluminum extrusion processing enterprise. The company operates four major industrial bases, including two in Nanhai and one in Xuzhou, Jiangsu, and boasts 83 internationally advanced aluminum extrusion production lines with an annual output of 500,000 tons[2][7]. Weiye Group owns three major brands: Weiye Aluminium, Weiye Doors and Windows, and Weiye Aluminium Furniture, serving a diverse range of industries from construction and transportation to electronics and custom home décor[2][7][10].

Weiye Group's commitment to innovation is evident in its establishment of an independent R&D center, a provincial "enterprise technology center," and a nationally recognized laboratory. The company holds:

- 12 independent core technologies

- 288 state-authorized patents (including 34 invention patents)

- 64 industry standard formulations and drafts

- 17 national standards[2]

Weiye is recognized as a national high-tech enterprise and has received numerous accolades, including "Top 500 Asia Brand," "Chinese Well-known Trademark," and "National Green Factory" awards[2][12].

Weiye offers a comprehensive range of aluminum profiles, including:

- Construction Series: Curtain wall profiles, formwork systems, louvers, tubes

- Industrial Series: Solar panel systems, mechanical accessories, motor shells

- Aluminum Doors & Windows and Aluminum Furniture[2][7][11][12]

Their products are widely used in construction, transportation, electronics, sanitary ware, customized home decoration, offices, and more.

Weiye's manufacturing facilities are equipped with:

- Asia's large-scale automatic vertical oxidation and electrophoresis production line

- 7,000-ton extruder in South China

- Full-automatic vertical storage systems

- Intelligent production systems for industrial lightweight development[2][7]

The company's strict adherence to international standards and military-grade quality control ensures consistent excellence across its product lines.

Weiye Group is deeply committed to sustainability, operating as a "National Green Factory" and prioritizing recycling, energy efficiency, and minimal waste in its processes. The company's green initiatives align with global trends toward eco-friendly manufacturing and sustainable construction[2][10][12].

With a brand rooted in China and a global supply chain service system, Weiye Group actively supports China's "Belt and Road Initiative" and aims to build an aluminum profile industry group with global influence. The company's vision is to improve the living environment for humanity and lead the industry's development through continuous technological innovation and intelligent manufacturing[2].

While Guangdong Weiye Group stands out for its scale, innovation, and influence, several other manufacturers are shaping the global aluminum extrusion landscape:

A Norwegian multinational, Norsk Hydro is a global leader in aluminum solutions, with a presence in over 40 countries. The company is renowned for its advanced extrusion technologies, sustainability initiatives, and comprehensive product offerings for construction, automotive, and industrial applications[8].

Headquartered in Japan, UACJ is a major supplier of high-quality aluminum extrusions for the automotive, electronics, and construction sectors. The company's focus on R&D and precision engineering has earned it international recognition[8].

Based in the Netherlands, Constellium specializes in advanced aluminum extrusions for aerospace, automotive, and industrial markets. The company is known for its lightweight, high-performance profiles and commitment to innovation[8].

A leading U.S. manufacturer, Kaiser Aluminum is recognized for its technical expertise and ability to deliver complex, high-strength extrusions for aerospace, automotive, and industrial applications[8].

India's Hindalco, part of the Aditya Birla Group, is a global leader in rolled and extruded aluminum products. Its subsidiary, Novelis, supplies the automotive, construction, and packaging industries worldwide[8].

Arconic, a spinoff from Alcoa, is a major player in North America and Europe, known for its architectural systems and high-quality extrusions for building, transportation, and aerospace markets[8].

India's largest manufacturer of aluminum extrusions, Jindal Aluminium, serves construction, transportation, and consumer durables sectors with a focus on quality and innovation[8].

A leading North American manufacturer, Bonnell Aluminum offers custom extrusions, fabrication, and finishing services for construction, transportation, and industrial markets[8][3].

Based in the UAE, Gulf Extrusions supplies architectural, industrial, and automotive profiles across the Middle East, Africa, and Europe, leveraging advanced manufacturing technologies[8].

Qatar Aluminum Extrusion Company (QALEX) is a key player in the Middle East, providing high-quality extrusions for construction and industrial applications[8].

The rapid growth of the electric vehicle (EV) sector is driving demand for lightweight aluminum extrusions in vehicle bodies, chassis, and battery packs. Aluminum's strength-to-weight ratio and corrosion resistance make it the material of choice for automotive innovation[4][6].

The global construction industry remains a primary driver of aluminum extrusion demand, particularly in windows, curtain walls, and structural frameworks. The market for aluminum in construction applications is projected to reach $22.81 billion by 2025[4][6].

- CNC Machining: High-precision fabrication of complex shapes is enabled by advanced CNC machining technologies, including milling, turning, drilling, and tapping[4].

- Surface Treatments: Enhanced anodizing, electrophoretic coating, and powder coating processes improve corrosion resistance, hardness, and UV protection for extruded profiles[4].

- Artificial Intelligence: AI-powered quality control systems, such as inline surface inspection and defect detection, are reducing waste and improving product consistency[8][9].

Manufacturers are prioritizing recycling, closed-loop production, and energy efficiency. Many companies have achieved "National Green Factory" status and are committed to reducing carbon emissions and increasing the use of recycled aluminum[2][6][10].

Customers increasingly demand bespoke profiles, integrated fabrication, and surface finishing services. Leading manufacturers offer design support, prototyping, and rapid delivery to meet diverse project requirements[3][5][11].

The aluminum extrusion profile industry in 2025 is defined by rapid growth, technological innovation, and a strong commitment to sustainability. Guangdong Weiye Group stands at the forefront, exemplifying excellence in scale, R&D, and global vision. Alongside other industry leaders such as Norsk Hydro, UACJ, Constellium, Kaiser Aluminum, and Hindalco, Weiye is shaping the future of aluminum extrusion with advanced manufacturing, intelligent quality control, and eco-friendly practices.

As demand for lightweight, durable, and sustainable materials accelerates across construction, transportation, and renewable energy sectors, aluminum extrusions will remain essential to modern industry. Whether you are seeking standard profiles or custom solutions, partnering with a top manufacturer like Weiye ensures access to cutting-edge technology, rigorous quality standards, and a forward-looking approach to innovation.

Guangdong Weiye Group distinguishes itself through its scale (83 advanced production lines and 500,000 tons annual output), technological innovation (288 state-authorized patents and a national laboratory), comprehensive product range, and commitment to sustainability. The company's global vision and robust R&D capabilities position it as a leader in the aluminum extrusion industry[2][7][12].

Aluminum extrusion profiles are widely used in construction (windows, doors, curtain walls), transportation (vehicle frames, rail components), electronics (heat sinks, enclosures), renewable energy (solar panel frames), and consumer goods. Their lightweight, strength, and corrosion resistance make them indispensable in modern engineering[4][6][11].

Top manufacturers are integrating artificial intelligence and advanced optical inspection systems for real-time defect detection and process optimization. This reduces waste, enhances product consistency, and minimizes manual inspection requirements, ensuring high-quality output[8][9].

Leading companies prioritize recycling, closed-loop production, and energy-efficient processes. Many have achieved "Green Factory" certifications and set ambitious targets for reducing carbon emissions and increasing the use of recycled aluminum, in line with global sustainability goals[2][10].

When selecting a supplier, consider factors such as production capacity, technical expertise, quality certifications, ability to deliver custom profiles, value-added services (e.g., machining, surface treatment), and global logistics support. Leading suppliers offer comprehensive design and prototyping assistance to ensure optimal results[3][5][11].

[1] https://www.weiye-aluminium.com/abo

[2] https://www.weiye-aluminium.com/aboutus.html

[3] https://hy-proto.com/top-aluminum-extrusion-manufacturers-compare

[4] https://www.archalu.com/aluminum-extrusion-industry-trends-and-innovations-in-2025/

[5] https://www.sourcifychina.com/top-extrusion-profile-manufacturers-compare/

[6] https://www.promarketreports.com/reports/aluminum-alloy-extrusion-profiles-95067

[7] https://www.weiye-aluminium.com/aluminum-profiles-factory.html

[8] https://www.thebusinessresearchcompany.com/report/aluminum-extrusion-global-market-report

[9] https://blog.tbrc.info/2025/03/aluminum-extrusion-industry/

[10] https://www.weiye-aluminium.com/aluminium-fabricator.html

[11] https://www.weiye-aluminium.com/aluminum-profiles.html

[12] https://www.weiye-aluminium.com/aluminium-industrial-profile-manufacturer.html

[13] https://www.weiye-aluminium.com

[14] https://www.weiye-aluminium.com/contactus.html

[15] https://www.weiye-aluminium.com/aluminum-solar-panel-system-factory.html

[16] https://www.weiye-aluminium.com/products.html

[17] https://www.sourcifychina.com/top-aluminium-extrusion-manufacturing-compare/

[18] https://www.shengxinglobal.com/blog/aluminum-extrusion-profiles-the-definitive-guide-2025.html

[19] https://www.precedenceresearch.com/aluminum-profiles-and-accessories-market

[20] https://www.coherentmarketinsights.com/market-insight/extruded-aluminum-profiles-market-4500

[21] https://www.researchandmarkets.com/reports/5685568/2025-aluminium-extrusion-market-outlook-report

[22] https://www.researchandmarkets.com/reports/5939172/aluminum-extrusion-market-report

[23] https://www.gii.co.jp/report/tbrc1672271-aluminum-extrusion-global-market-report.html

[24] https://www.aporesearch.com/reports/chemical-material/global-aluminum-extruded-products-industry-research-report-2025

[25] https://www.technavio.com/report/aluminum-extrusion-market-industry-analysis

[26] https://edmolimited.co.uk/education/frequently-asked-questions/aluminium-extrusion/

[27] https://estar.jp/novels/26368215/viewer?page=1

[28] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[29] https://www.globenewswire.com/news-release/2024/11/21/2985360/0/en/North-America-Aluminum-Extrusion-Market-Size-to-Surpass-USD-18-56-Bn-by-2033.html

[30] https://www.weiye-aluminium.com/technology.html

[31] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/manufacturing-custom-aluminum-extrusion-profiles/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden