English

Views: 222 Author: Astin Publish Time: 2025-04-17 Origin: Site

Content Menu

● Understanding Aluminum Extrusion

● 1. Profile Shape and Complexity

● 2. Wall Thickness Considerations

● 3. Material Selection: Alloy and Temper

● 4. Dimensional Tolerances and Specifications

● 5. Symmetry and Structural Design

● 6. Surface Finish and Decoration

● 7. Manufacturing and Cost Considerations

● 8. Joining, Assembly, and Secondary Operations

● 9. Use of Design Software and Simulation

● 10. Design Checklist for Aluminum Extrusion

● Frequently Asked Questions (FAQ)

>> 1. What is the ideal wall thickness for aluminum extrusion profiles?

>> 2. Why are rounded corners preferred over sharp corners in extrusion design?

>> 3. How does alloy selection affect aluminum extrusion design?

>> 4. What role does symmetry play in aluminum extrusion profiles?

>> 5. How can CAD and simulation tools improve extrusion profile design?

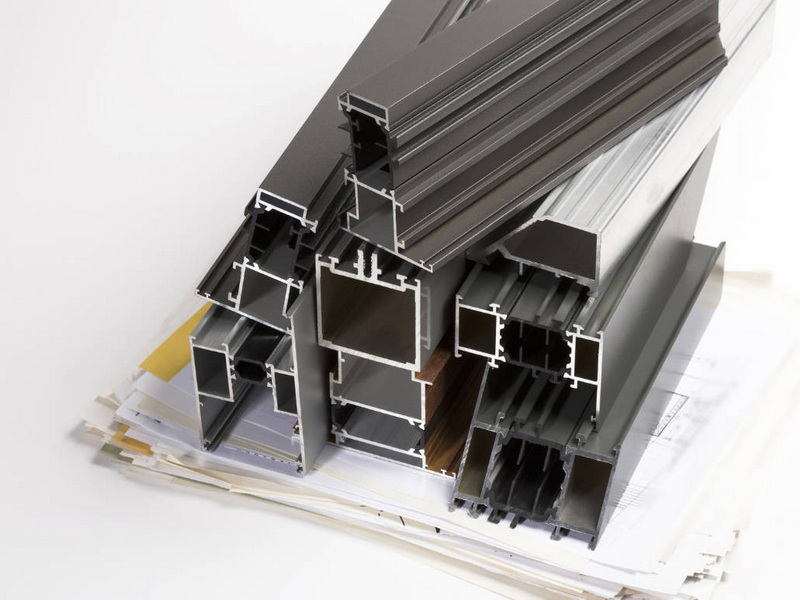

Aluminum extrusion is a versatile manufacturing process that enables the creation of complex, lightweight, and strong profiles for a wide range of applications—from architectural frameworks to automotive components and consumer electronics. The success of any aluminum extrusion project hinges on careful attention to design principles that balance functionality, manufacturability, cost, and performance. This comprehensive guide explores the key factors in aluminum extrusion profile design, offering practical insights for engineers, designers, and manufacturers.

Aluminum extrusion involves forcing a heated aluminum billet through a specially designed die to produce profiles with uniform cross-sections. These profiles can be solid, hollow, or semi-hollow, and their final properties are determined by a combination of design, material selection, and processing parameters[3].

Simplicity and Uniformity

- Simple, symmetrical profiles are easier and more cost-effective to extrude[7].

- Uniform wall thickness throughout the profile ensures even metal flow, reducing stress, distortion, and the risk of defects[1][2][5][7].

- Complex shapes with deep cavities, sharp corners, or protrusions are challenging to extrude and may compromise die life and product quality[7].

Rounded Corners and Fillets

- Sharp corners are difficult to achieve and can weaken the profile; rounded corners (with a radius of 0.5–1 mm) improve metal flow and structural integrity[1][2][4][7].

- Fillets and radii at transitions between thick and thin sections help streamline the flow and minimize stress concentrations[2][4].

Channel Ratios

- For profiles with channels, maintain a height-to-width ratio of approximately 3:1 to ensure die strength and extrudability[4].

- Avoid deep, narrow channels or "hollows within hollows," as these are difficult to extrude and may result in defects[6].

Uniform Wall Thickness

- Uniform wall thickness is crucial for maintaining strength and reducing the risk of defects such as warping or uneven cooling[1][2][5][6][7].

- Large variations in wall thickness can cause dimensional control problems and visible surface imperfections, especially after anodizing[1][2].

Minimum and Maximum Thickness

- The minimum wall thickness is determined by the alloy, profile complexity, and application requirements[5][7].

- Thicker walls provide greater strength but increase weight and cost; thinner walls save material but may compromise structural performance[7].

Streamlined Transitions

- Where changes in wall thickness are necessary, transitions should be gradual and rounded, not abrupt[2][4].

Choosing the Right Alloy

- The selection of aluminum alloy depends on the required strength, corrosion resistance, machinability, and intended application[7][8].

- Common alloys for extrusion include 6063 (excellent for architectural applications), 6061 (higher strength), and others tailored for specific properties[8].

Temper Designation

- The temper (such as T5 or T6) indicates the heat treatment and mechanical properties of the extruded profile[3].

- The choice of temper affects the profile's hardness, strength, and formability.

Tolerances

- Tolerances define the allowable variation in profile dimensions, impacting fit, function, and assembly[5][7].

- Tighter tolerances increase manufacturing complexity and cost; balance precision requirements with feasibility[2][5][7].

Profile Size Limitations

- The profile size must be compatible with available extrusion press capabilities[7].

- Oversized or undersized profiles may require special tooling or presses, affecting cost and lead time.

Symmetry

- Symmetrical profiles are easier to extrude and result in more consistent mechanical properties[1][5][7].

- Asymmetrical designs may require additional support during extrusion and can lead to uneven flow or distortion[2][7].

Structural Features

- Incorporate ribs, webs, or gussets to enhance strength without excessive material use[2][6].

- Hollow sections are possible but should be designed with accessible internal features for manufacturability[6].

Surface Treatment

- Specify required surface finishes (anodizing, powder coating, etc.) during the design stage to ensure protection and aesthetics[1][7].

- Surface treatments can enhance corrosion resistance, improve appearance, and hide minor imperfections[1].

Decorative Features

- Well-designed decorative elements can also serve functional purposes, such as hiding process-related marks or protecting against handling damage[1].

Extrusion Ratio

- The extrusion ratio (billet cross-sectional area to profile cross-sectional area) affects the force required and the feasibility of the design[7].

- High extrusion ratios increase production difficulty and cost.

Die Design

- Die complexity directly impacts profile quality and production cost[3][7].

- Simple, robust dies are less prone to failure and produce more consistent profiles.

Production Volume

- High-volume production justifies investment in complex dies and tighter tolerances; low-volume runs benefit from simpler designs[7].

Cost Optimization

- Minimize material usage by optimizing wall thickness and eliminating unnecessary features[7].

- Design for ease of extrusion, assembly, and finishing to reduce overall production costs[1][7].

Joining Methods

- Consider how the profile will be joined to other components—welding, mechanical fastening, or adhesives—and design features accordingly[7].

Machining and Fabrication

- Plan for secondary operations such as drilling, tapping, or cutting; include index marks or features to facilitate these processes[2].

Packaging and Handling

- Design profiles to minimize damage during handling, shipping, and storage[2].

CAD Tools

- Computer-Aided Design (CAD) software enables precise modeling, simulation, and optimization of extrusion profiles[5][7].

- Simulation tools can predict metal flow, identify potential defects, and optimize die design before production begins[7].

A comprehensive design checklist ensures all critical aspects are addressed before production[2]:

- End-use requirements

- Alloy and temper selection

- Wall thickness and uniformity

- Tolerances and specifications

- Surface finish and decoration

- Profile symmetry and structural features

- Joining and assembly considerations

- Secondary fabrication requirements

- Quantity and production volume

- Packaging, handling, and shipping

- Required delivery dates

Designing aluminum extrusion profiles is a multidisciplinary task that requires balancing structural requirements, manufacturability, cost, and aesthetics. Key factors such as profile shape, wall thickness, material selection, tolerances, symmetry, surface finish, and manufacturing constraints must all be carefully considered. Employing modern CAD tools and simulation software can streamline the design process, minimize errors, and optimize both performance and cost. By adhering to best practices and collaborating closely with extrusion specialists, designers can ensure the success of their aluminum extrusion projects across diverse industries.

The ideal wall thickness depends on the profile's application, required strength, and the chosen alloy, but maintaining uniform wall thickness is crucial. Thicker walls increase strength but also add weight and cost, while thinner walls save material but may compromise structural integrity. Gradual transitions between wall thicknesses are recommended to avoid defects[1][2][5][7].

Rounded corners improve metal flow during extrusion, reduce stress concentrations, and enhance the structural integrity of the profile. Sharp corners are difficult to achieve, can weaken the profile, and often require additional post-processing[1][2][4][7].

Alloy selection determines the profile's mechanical properties, corrosion resistance, and suitability for specific applications. Different alloys offer varying strengths, formability, and surface finish characteristics. The chosen alloy must match the intended use and environmental conditions[7][8].

Symmetrical profiles are easier to extrude, result in more uniform mechanical properties, and reduce the risk of defects. Asymmetrical profiles can cause uneven metal flow, leading to distortion or inconsistent quality[1][5][7].

CAD and simulation tools enable designers to create precise models, simulate the extrusion process, and predict potential issues before production. This helps optimize the design for manufacturability, minimize defects, and reduce costly errors[5][7].

[1] https://www.shapesbyhydro.com/en/design-thinking/extrusion-quick-guide-for-designing-with-aluminium/

[2] https://www.bwcprofiles.co.uk/extrusion-academy/aluminium-extrusion-design-best-practices

[3] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[4] https://get-it-made.co.uk/guides/aluminium-extrusion-guide

[5] https://www.yjing-extrusion.com/what-are-the-key-considerations-in-aluminum-extrusion-design.html

[6] https://www.nicerapid.com/project/considerations-when-designing-parts-for-aluminum-extrusion/

[7] https://www.linkedin.com/pulse/designing-aluminum-profiles-key-considerations-engineers-grihc

[8] http://scaluminum.com/2014/02/aluminum-extrusion-design-key-specs-that-must-be-considered/

[9] https://aec.org/key-design-considerations

[10] https://jmaluminium.com/things-to-consider-when-selecting-aluminium-extrusion-profile/

[11] http://scaluminum.com/2015/10/extrusion-101-how-to-design-your-own-custom-aluminum-products/

[12] https://www.youtube.com/watch?v=yqKK5SI2Gzg

[13] https://www.gabrian.com/custom-aluminum-extrusions-design-tips/

[14] https://profileprecisionextrusions.com/design-guide/

[15] https://www.comhan.com/en/blog/customized-aluminum/aluminium-extrusion-5-tips-design-aluminium-profiles-efficiently-and

[16] https://capalex.co.uk/extrusion-design-considerations/aluminium-design-considerations

[17] https://www.howardprecision.com/five-tips-to-achieve-a-successful-aluminum-extrusion-design/

[18] https://hydal.se/wp-content/uploads/2019/10/Hydal_ExtrusionDesignManual_2019_EN-complete_low_rev-1.pdf

[19] https://vention.io/resources/guides/t-slot-aluminum-extrusion-structure-design-guide-77

[20] https://aec.org/extrusion-design-tips

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden