English

Views: 222 Author: Astin Publish Time: 2025-05-15 Origin: Site

Content Menu

● Leading Aluminum Profile Suppliers in China

>> Foshan Shenghai Aluminum Co., Ltd.

>> Guangdong Fenglu Aluminium Company

>> Zhaoqing Asia Aluminum Factory Company Limited

>> Guangdong Xingfa Aluminium Co., Ltd.

>> Guangdong Strong Metal Products Co., Ltd.

>> Henan Huayang Aluminum Co., Ltd.

● Detailed Manufacturing Process of Aluminum Profiles

● Technological Innovations in the Aluminum Profile Industry

● Case Studies: Successful Projects Using Chinese Aluminum Profiles

● Market Trends and Future Outlook

● Challenges and Solutions in the Aluminum Profile Supply Chain

● Expanded Applications of Aluminum Profiles in Various Industries

● Customer Service and After-Sales Support

● International Certifications and Compliance

● Customization and Innovation Examples

● Future Collaboration Opportunities

● Frequently Asked Questions (FAQ)

>> 1. What factors should I consider when choosing an aluminum profile supplier in China?

>> 2. Are Chinese aluminum profiles compliant with international quality standards?

>> 3. Can I get customized aluminum profiles from Chinese suppliers?

>> 4. How do Chinese aluminum profile manufacturers ensure product quality?

>> 5. What industries commonly use aluminum profiles from China?

China has emerged as a global powerhouse in aluminum profile manufacturing, offering a diverse range of suppliers renowned for their innovation, quality, and ability to serve a multitude of industries. Whether your business operates in construction, automotive, electronics, or renewable energy, sourcing aluminum profiles from China provides access to advanced technology, custom solutions, and competitive pricing. This comprehensive article explores the best aluminum profile suppliers in China, highlighting their expertise, product range, and what sets them apart in the global market. You'll also find detailed insights into manufacturing processes, technological innovations, industry applications, and future trends.

WEIYE Aluminum is a benchmark in the Chinese aluminum profile industry, recognized for its commitment to quality, innovation, and customer satisfaction. As a trusted partner for clients worldwide, WEIYE delivers high-quality aluminum profiles tailored for various industries and applications.

Key Strengths:

- Expertise in both standard and custom aluminum profiles, from simple geometric shapes to complex, application-specific designs.

- Comprehensive manufacturing process, including alloy selection, extrusion, surface treatment (anodizing, powder coating, polishing, brushing), and rigorous quality control.

- Strong focus on sustainability, utilizing recyclable materials and energy-efficient production methods.

- Extensive experience in providing solutions for construction, transportation, industrial machinery, electronics, furniture, and renewable energy sectors.

Product Range:

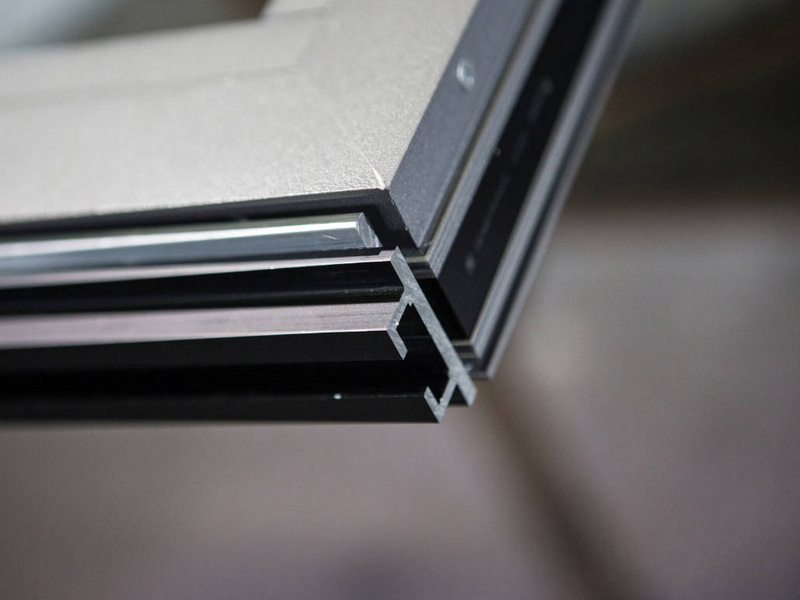

- Window and door frames, curtain wall systems, structural framing, railings, and partition systems for construction.

- Vehicle frames, railway components, marine applications, and bicycle frames for the transportation sector.

- Industrial profiles for conveyor systems, machine enclosures, workstations, and robotic components.

- Solar panel frames, wind turbine components, and heat exchangers for renewable energy.

- Heat sinks, LED lighting fixtures, electronic housings, and cable management systems for electronics.

- Modular furniture, display stands, shelving units, and decorative elements for interior design.

Why Choose WEIYE:

- Advanced extrusion technology ensures precision and consistency.

- Customization options to meet specific project requirements.

- Commitment to sustainable and environmentally friendly practices.

- Strong after-sales support and technical expertise.

Foshan Shenghai Aluminum is a leading manufacturer known for its custom-made aluminum profiles and strict adherence to international quality standards. The company serves a global clientele, offering innovative solutions for diverse applications.

As one of the largest aluminum extrusion manufacturers in Asia, Zhongwang Aluminium is celebrated for its advanced technology, extensive R&D, and eco-friendly production. Their comprehensive product range and global reach make them a preferred choice for large-scale projects.

Fenglu Aluminium boasts impressive production capacity and a wide array of patented products. Its high-end decorative aluminum materials and architectural systems are exported to over 100 countries, making it a major player in the industry.

JMA Aluminium specializes in modern building materials, including doors, windows, and curtain walls. With three large factories and a reputation for quality, JMA serves both domestic and international markets.

Asia Aluminium is known for its high-precision manufacturing and strong brand recognition. The company focuses on windows, doors, and curtain wall systems, with a significant presence in global markets.

Xingfa Aluminium is a pioneer in architectural aluminum, offering innovative solutions for both industrial and construction applications. Their intelligent production methods and competitive pricing set them apart.

Strong Metal Products specializes in custom aluminum profiles, CNC machining, and advanced surface treatments. Their products are widely used in construction, automotive, and electronics.

Henan Huayang Aluminum emphasizes R&D and deep processing, producing innovative aluminum products for a variety of industries. Their commitment to quality and customer satisfaction drives their growth.

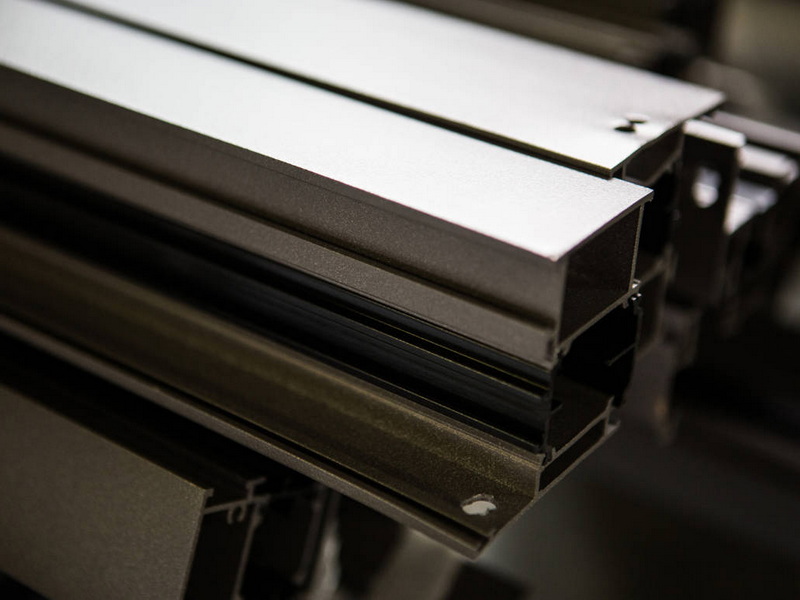

The manufacturing of aluminum profiles involves several critical steps to ensure the final product meets the required specifications and quality standards. The process begins with the selection of high-quality aluminum alloys, chosen based on the intended application and performance requirements. These alloys are melted and cast into billets, which serve as the raw material for extrusion.

Extrusion is the core process in aluminum profile manufacturing. The billets are heated to a specific temperature to make the aluminum malleable and then forced through a die with the desired cross-sectional shape. This process requires precision and advanced machinery to maintain consistent dimensions and surface quality. After extrusion, the profiles undergo various treatments such as stretching to relieve internal stresses, aging to enhance mechanical properties, and surface finishing to improve appearance and corrosion resistance.

Surface treatments are vital for enhancing the durability and aesthetics of aluminum profiles. Common treatments include anodizing, which creates a protective oxide layer; powder coating, which provides color and additional protection; and polishing or brushing for decorative finishes. These treatments not only improve the product's lifespan but also expand its application possibilities.

Chinese aluminum profile manufacturers have embraced technological advancements to stay competitive globally. Automation and digitalization have transformed production lines, enabling higher precision and efficiency. Computer numerical control (CNC) machines are widely used for cutting, drilling, and machining profiles to exact specifications.

Research and development efforts focus on developing new alloys with improved strength-to-weight ratios and corrosion resistance. Innovations in extrusion technology, such as multi-hole dies and advanced cooling systems, allow for more complex shapes and faster production cycles. Additionally, environmentally friendly manufacturing practices, including energy-efficient furnaces and recycling of scrap materials, are becoming standard.

Several high-profile projects worldwide have utilized Chinese aluminum profiles due to their quality and cost-effectiveness. For instance, a major commercial skyscraper in Dubai incorporated custom aluminum curtain walls supplied by a leading Chinese manufacturer, achieving both aesthetic appeal and energy efficiency.

In Europe, a transportation company used aluminum profiles from China for lightweight railway components, significantly reducing vehicle weight and improving fuel efficiency. Similarly, in the renewable energy sector, Chinese aluminum frames have been integral to the installation of large-scale solar farms, providing durable and corrosion-resistant support structures.

The demand for aluminum profiles continues to grow globally, driven by trends such as urbanization, green building initiatives, and the expansion of electric vehicles. China is expected to maintain its leadership in this sector by investing in smart manufacturing and expanding export markets.

Emerging technologies like 3D printing and advanced composites may complement traditional aluminum profiles, offering new design possibilities. Furthermore, the push for sustainability will encourage manufacturers to adopt circular economy principles, focusing on recycling and reducing environmental impact.

Despite its strengths, the aluminum profile industry faces challenges such as raw material price volatility, trade regulations, and logistics complexities. Chinese suppliers mitigate these issues through strategic sourcing, maintaining strong relationships with bauxite producers, and optimizing supply chain management.

To address trade barriers, many manufacturers have established overseas offices and partnerships to facilitate smoother transactions and local support. Advances in digital supply chain technologies, including blockchain and IoT, are also being explored to enhance transparency and efficiency.

Aluminum profiles from China are increasingly favored across a wide range of industries due to their versatility and performance. In the construction sector, beyond windows and doors, aluminum profiles are used in curtain walls, roofing systems, and interior partitions, offering lightweight yet strong solutions that enhance building aesthetics and energy efficiency.

In the automotive industry, aluminum profiles contribute to vehicle lightweighting, which is crucial for improving fuel efficiency and reducing emissions. They are used in chassis components, heat exchangers, and decorative trims, often customized to meet stringent safety and performance standards.

The electronics industry benefits from aluminum profiles in heat dissipation applications, such as LED lighting fixtures and electronic housings, where thermal management is critical. Additionally, aluminum's excellent conductivity and corrosion resistance make it ideal for cable management systems.

Furniture manufacturers utilize aluminum profiles for modular designs, allowing for easy assembly and reconfiguration. The renewable energy sector relies heavily on aluminum profiles for solar panel frames and mounting systems, which must withstand harsh environmental conditions while maintaining structural integrity.

Leading Chinese aluminum profile suppliers prioritize customer satisfaction through comprehensive service offerings. This includes technical consultation during the design phase, timely delivery schedules, and responsive after-sales support. Many companies provide on-site assistance and training to ensure proper installation and maintenance of aluminum products.

Strong communication channels and multilingual support teams help international clients navigate complex projects smoothly. Warranty programs and quality guarantees further build trust and long-term partnerships.

To meet the demands of global markets, Chinese aluminum profile manufacturers obtain various international certifications. These include ISO9001 for quality management, ISO14001 for environmental management, and certifications specific to construction and automotive standards.

Compliance with regulations such as REACH and RoHS ensures that products are safe and environmentally friendly. These certifications not only demonstrate commitment to quality but also facilitate smoother customs clearance and market acceptance.

Customization is a hallmark of Chinese aluminum profile suppliers. For example, some manufacturers offer profiles with integrated thermal breaks to improve insulation in building applications. Others develop anodized finishes with unique colors and textures to meet architectural design trends.

Innovations also include modular framing systems that allow for quick assembly and disassembly, catering to industries like exhibition stands and industrial automation. Advanced surface treatments, such as anti-fingerprint coatings and enhanced corrosion resistance, further expand the usability of aluminum profiles.

As the global demand for aluminum profiles continues to rise, Chinese suppliers are actively seeking partnerships with international companies to foster innovation and expand market reach. Collaborative efforts focus on co-developing new materials, improving production technologies, and enhancing sustainability practices.

These partnerships enable knowledge exchange and help suppliers tailor products to meet specific regional requirements, ensuring mutual growth and success in a competitive global market.

China's aluminum profile industry combines scale, technology, and customer-centric approaches to deliver high-quality, customizable products. With continuous innovation and a commitment to sustainability, Chinese suppliers are well-positioned to meet the evolving needs of diverse industries worldwide. Companies like WEIYE Aluminum, Foshan Shenghai Aluminum, Zhongwang Aluminium, Fenglu Aluminium, and others exemplify the strength and diversity of China's aluminum industry. For businesses seeking reliable aluminum profile partners, China offers unmatched expertise, innovation, and value.

When selecting a supplier, focus on their production capacity, technological capabilities, quality certifications, customization options, pricing, and after-sales service. It's also important to check their export experience and client references.

Yes, leading Chinese manufacturers adhere to international standards such as ISO9001 and often hold additional certifications to ensure their products meet global quality and safety requirements.

Most top Chinese aluminum profile suppliers offer customization services, allowing clients to specify dimensions, alloys, surface treatments, and design features to meet specific project requirements.

They implement rigorous quality control processes, including raw material inspection, in-process monitoring, final product testing, and certifications. Many use advanced technology and automated lines to maintain consistency.

Aluminum profiles from China are widely used in construction, automotive, electronics, furniture, renewable energy, and industrial manufacturing due to their lightweight, strength, and corrosion resistance.