English

Views: 222 Author: Astin Publish Time: 2025-04-21 Origin: Site

Content Menu

● Understanding T-Slot Aluminum Extrusion Profiles

>> What Is a T-Slot Aluminum Extrusion?

>> How Are T-Slot Aluminum Extrusions Manufactured?

● Key Advantages of T-Slot Aluminum Extrusion Profiles

>> 1. Modularity and Flexibility

>> 2. Strength-to-Weight Ratio

>> 4. Cost and Labor Efficiency

>> 5. Customization and Accessories

● Common Applications of T-Slot Aluminum Extrusion Profiles

>> 1. Industrial Machinery and Automation

>> 2. Safety Enclosures and Guarding

>> 3. Workstations, Benches, and Tables

>> 4. Material Handling and Storage

>> 5. Furniture and Architectural Applications

>> 6. Medical and Laboratory Equipment

>> 7. Automotive and Aerospace

>> 8. Renewable Energy and Solar

>> 9. DIY, Maker, and Hobbyist Projects

● Comparing T-Slot Aluminum to Other Framing Systems

>> T-Slot vs. V-Slot and Dovetail Profiles

● Selecting the Right T-Slot Profile for Your Project

● Design and Assembly Considerations

>> 1. Fasteners and Connectors

>> 2. Accessories and Panel Integration

● Sustainability and Environmental Impact

● FAQ: T-Slot Aluminum Extrusion Profiles

>> 1. What are the main benefits of using T-slot aluminum extrusions over welded steel frames?

>> 2. In which industries are T-slot aluminum profiles most commonly used?

>> 3. How do I choose the right size T-slot profile for my project?

>> 4. Can T-slot aluminum extrusions be used outdoors or in harsh environments?

>> 5. What accessories and connectors are available for T-slot aluminum profiles?

T-slot aluminum extrusion profiles have revolutionized the way engineers, manufacturers, and even hobbyists design and build structures. Their modularity, strength, and adaptability have made them a staple across industries ranging from manufacturing and automation to architecture and home improvement. But what exactly are T-slot aluminum extrusions, and why are they so widely used? This comprehensive article explores the structure, benefits, and diverse applications of T-slot aluminum profiles, providing an in-depth look at their role in modern engineering and design.

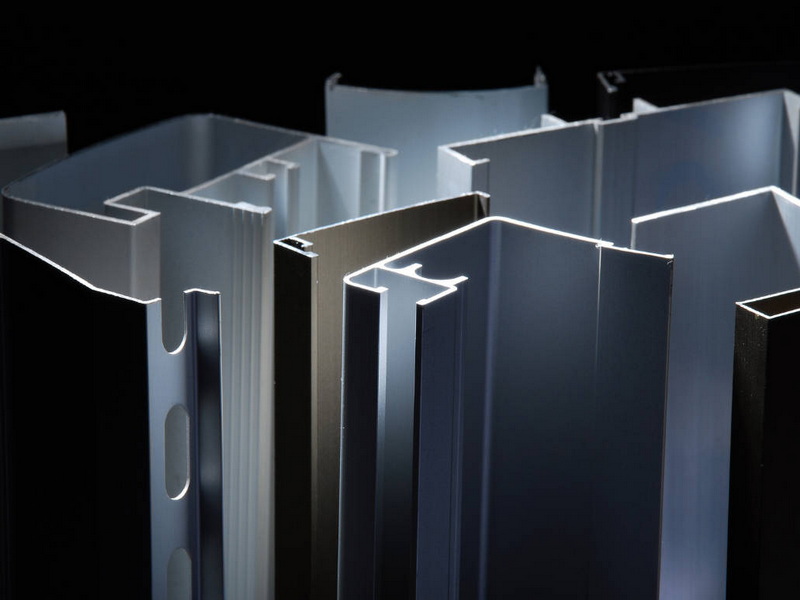

A T-slot aluminum extrusion is a length of aluminum that has a cross-sectional groove shaped like the letter "T" running along one or more sides. This groove allows for the easy insertion of specialized fasteners and connectors, enabling rapid assembly of frames and structures without the need for welding or complex fabrication techniques[4][2][7].

The profiles are typically made from high-strength aluminum alloys such as 6063-T5 or 6105-T5, which offer excellent mechanical properties, corrosion resistance, and a lightweight structure[6][4]. The T-slot design allows users to slide nuts and bolts into the grooves, securing components at any point along the profile.

T-slot profiles are produced through an extrusion process in which heated aluminum billets are forced through a die to create the desired cross-sectional shape. After extrusion, the profiles are often anodized or coated to enhance their corrosion resistance and appearance[2][7]. The result is a versatile building block that can be cut to custom lengths and assembled with a wide range of accessories.

- Easy Assembly and Disassembly: T-slot profiles can be assembled and reconfigured using simple hand tools, making them ideal for projects that require frequent modifications[2][5].

- Expandable: Structures built with T-slot extrusions can be expanded or altered without the need for cutting or welding, simply by adding or moving connectors and accessories[5][7].

- Aluminum is about one-third the weight of steel but offers comparable strength for many applications. This makes T-slot extrusions strong yet easy to handle and transport[2][7].

- The natural oxide layer on aluminum, often enhanced through anodizing, provides excellent protection against corrosion, making T-slot profiles suitable for both indoor and outdoor use[2][7].

- Reduced Fabrication Time: No welding, drilling, or painting is required, significantly reducing labor and fabrication costs[5].

- Lower Maintenance: Damaged or worn components can be replaced individually without dismantling the entire structure[5].

- A vast ecosystem of connectors, panels, hinges, feet, wheels, and other accessories allows users to create highly customized solutions for any application[10][7].

T-slot aluminum extrusions are used in a remarkable variety of industries and projects due to their adaptability and performance. Below are some of the most common and impactful applications:

- Machine Frames and Bases: T-slot extrusions are the backbone of custom machine frames, offering strength and flexibility for mounting motors, sensors, and other components[1][6][7].

- Automation Systems: They form the structural framework for conveyor systems, robotic cells, and automated assembly lines, where frequent reconfiguration is often required[1][3][7].

- Linear Motion Systems: T-slot profiles can serve as rails for linear slides and carriages, supporting precise and controlled movement in automation setups[1].

- Equipment Safety Enclosures: T-slot frames are commonly used to build safety guards and enclosures around machinery, protecting operators from moving parts and debris[1][6].

- Laser and Climate Control Enclosures: Their modularity allows for the creation of custom enclosures for sensitive processes or environments[7].

- Custom Workstations: Laboratories, assembly lines, and workshops use T-slot profiles to create ergonomic and adjustable workstations tailored to specific tasks[1][7][11].

- Workbenches and Packing Stations: The profiles' strength supports heavy loads, while their modularity allows for easy integration of shelves, tool holders, and lighting[11].

- Carts and Trolleys: Lightweight yet strong, T-slot extrusions are ideal for building mobile carts and trolleys for transporting materials[6][7].

- Shelving and Storage Racks: Retailers and warehouses use T-slot frames for customizable shelving and storage solutions that can be reconfigured as needs change[7][11].

- Office and Workshop Furniture: Desks, cabinets, and storage units can be built to precise specifications using T-slot extrusions, with a modern industrial aesthetic[1][7].

- Partitions and Display Units: Modular office partitions, trade show displays, and retail fixtures benefit from the adaptability and clean appearance of T-slot frames[7][11].

- Architectural Features: Window and door frames, sign frames, and even structural elements in modular buildings can be constructed using T-slot profiles[6][7].

- Medical Device Frames: The cleanliness and corrosion resistance of anodized aluminum make T-slot extrusions suitable for medical equipment and laboratory apparatus[6][7].

- Cleanroom Structures: T-slot frames can be used to build modular cleanrooms and laboratory enclosures, supporting strict hygiene requirements[7].

- Vehicle Components: T-slot aluminum is increasingly used in automotive manufacturing for constructing frames, fixtures, and even certain vehicle parts due to its vibration resistance and light weight[9].

- Aerospace Structures: The strength-to-weight ratio and machinability of T-slot extrusions make them valuable in the creation of lightweight, durable aerospace components[9].

- Solar Panel Frames: T-slot profiles are ideal for mounting solar panels, offering corrosion resistance and easy adjustability for optimal positioning[7].

- Wind and Hydro Installations: Modular frames for small-scale wind turbines and hydroelectric systems can be quickly assembled using T-slot extrusions.

- 3D Printers and CNC Machines: The precision and modularity of T-slot profiles make them the standard for building custom 3D printers, CNC routers, and laser cutters[4].

- Home Automation and Improvement: From smart mirrors to automated curtain systems, T-slot aluminum enables creative home projects with professional results[9].

Feature | T-Slot Aluminum | Welded Steel |

Assembly | Modular, no welding needed | Requires welding and finishing |

Modification | Easy to reconfigure | Difficult, requires cutting |

Weight | Lightweight | Heavy |

Corrosion Resistance | Excellent (anodized) | Needs painting/coating |

Cost | Lower labor, higher material | Higher labor, lower material |

Maintenance | Easy to repair/replace parts | Repairs are labor-intensive |

T-slot aluminum offers significant advantages in flexibility, speed, and maintenance over traditional welded steel frames, especially in environments where change and adaptability are important[5].

- V-Slot: A variation with V-shaped grooves, often used for linear motion in 3D printers and CNC machines[4].

- Dovetail: Provides superior stability in high-vibration environments but is less modular than T-slot systems[3].

T-slot profiles come in a variety of sizes and strengths, typically categorized by their cross-sectional dimensions (e.g., 20x20mm, 30x30mm, 40x40mm, 50x50mm)[4][11]. The choice depends on:

- Load Requirements: Heavier loads require larger profiles (e.g., 50 series for industrial machinery)[11].

- Application Type: Lightweight applications (e.g., small enclosures) can use smaller profiles (e.g., 20 or 30 series)[11].

- Available Space: Compact profiles are ideal for projects with space constraints[11].

Consulting with suppliers or using engineering load calculators can help determine the optimal profile for your specific needs[10][11].

A wide range of fasteners—such as T-nuts, corner brackets, hinges, and joining plates—are available to connect T-slot profiles in various configurations[4][10]. The choice of connector depends on the required strength, desired appearance, and ease of assembly.

T-slot frames can be customized with panels (acrylic, polycarbonate, mesh, etc.), casters, leveling feet, handles, and more. This allows for the creation of enclosures, cabinets, and mobile units tailored to specific requirements[10][6].

Profiles are available in anodized, powder-coated, or painted finishes, offering both aesthetic and functional benefits such as enhanced corrosion resistance and color coding[2][6][7].

For high-precision applications, such as linear motion systems, it is important to select profiles with tight tolerances and minimal warping. Not all manufacturers adhere to the same quality standards, so verifying specifications is crucial for demanding projects[10].

Aluminum is highly recyclable, and many T-slot profiles are made from recycled material. The ability to disassemble and reuse components further reduces waste and environmental impact, supporting sustainable manufacturing practices[7].

While T-slot aluminum extrusions offer many advantages, certain limitations should be considered:

- Dynamic Environments: In applications with heavy vibration or shock, connections may require periodic tightening or additional bracing to maintain alignment[3].

- Heavy Loads: For extremely heavy or critical load-bearing applications, alternative framing systems or reinforced designs may be necessary[3][11].

- Cost: While labor and maintenance costs are lower, the raw material cost of aluminum can be higher than steel, especially for large-scale projects[5].

T-slot aluminum extrusion profiles have become an indispensable tool across industries due to their modularity, strength, and ease of use. From industrial automation and machinery to furniture, architecture, and DIY projects, their adaptability allows for creative and cost-effective solutions. With a vast array of sizes, accessories, and finishes, T-slot profiles empower engineers, designers, and makers to bring their ideas to life with efficiency and precision. As technology and manufacturing continue to evolve, the role of T-slot aluminum extrusions is only set to grow, driving innovation in countless fields.

T-slot aluminum extrusions offer modularity, easy reconfiguration, lightweight strength, corrosion resistance, and reduced fabrication time and cost. Unlike welded steel, they require no welding or painting, and modifications can be made without cutting or re-welding, making them ideal for projects that require flexibility and frequent changes[5][2][7].

They are widely used in manufacturing (machine frames, automation systems), safety guarding (enclosures, barriers), material handling (carts, racks), furniture (desks, cabinets), architecture (window frames, partitions), medical and laboratory equipment, automotive, aerospace, renewable energy (solar panel frames), and DIY/maker projects[1][6][7][9].

Profile size should be selected based on the load requirements, available space, and application type. Smaller profiles (e.g., 20 series) are suitable for lightweight or space-constrained projects, while larger profiles (e.g., 50 series) are designed for heavy-duty industrial applications. Consulting with suppliers or using engineering calculators helps ensure optimal selection[11][10].

Yes, T-slot aluminum extrusions are highly resistant to corrosion, especially when anodized or coated. This makes them suitable for outdoor use and harsh environments, including exposure to moisture, chemicals, and UV radiation[2][7][6].

A wide variety of accessories are available, including T-nuts, corner brackets, joining plates, hinges, handles, leveling feet, casters, and panel holders. These enable the construction of complex structures, enclosures, cabinets, and mobile units, tailored to specific requirements[4][10][6].

[1] https://www.gabrian.com/what-is-t-slot-aluminum/

[2] https://www.chaluminium.com/everything-you-need-to-know-about-t-slot-aluminum

[3] https://proax.ca/en/blog/post/t-slot-vs-dovetail-aluminum-extrusion-comparison

[4] https://en.wikipedia.org/wiki/T-slot_structural_framing

[5] https://framingtech.com/faqs/t-slot-aluminum/why-choose-t-slotted-aluminum-over-welded-steel

[6] https://www.wellste.com/t-slot-aluminum-extrusion/

[7] https://www.gj-alu.com/news/everything-you-need-to-know-about-t-slot-aluminum-profiles.html

[8] https://www.phidgets.com/docs/T-Slot_Guide

[9] https://www.alineautomation.com/the-many-uses-and-applications-of-t-slot-aluminum/

[10] https://www.industrialprofile.com/t-slot-aluminum-essential-tips-to-keep-in-mind-when-purchasing/

[11] https://www.gapengineering.com.au/blog/which-size-profile-is-the-right-one-for-my-project/

[12] https://amcaluminum.ph/uses-t-slot-aluminum/

[13] https://vention.io/resources/guides/t-slot-aluminum-extrusion-structure-design-guide-77

[14] https://8020.net/framing-options/t-slotted-profiles.html

[15] https://www.industrialprofile.com/learn/profile/

[16] http://www.rmmc.net/8020/faq

[17] https://www.gapengineering.com.au/blog/a-complete-guide-to-t-slot-aluminium-extruded-profiles/

[18] https://www.tslots.com/tech-info-resources/faq/

[19] https://www.alufabinc.com/faqs/

[20] https://www.reddit.com/r/CNC/comments/1h6qdlo/question_about_tslot_extrusion/

[21] https://parco-inc.com/t-slot-aluminum-frequently-asked-questions/

[22] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[23] https://ai.motion.com/what-t-slot-aluminum-extrusion-do-i-use/

[24] https://www.fonnovaluminium.com/es/slotted-profile/

[25] https://parco-inc.com/choosing-t-slot-accessories/

[26] https://www.framingtech.com/blog/t-slot-aluminum-profiles-in-inch-vs-metric-systems-how-do-they-measure-up

[27] https://haluminium.com/hoonly-aluminium-extrusion-profile-faq/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden