English

Views: 222 Author: Astin Publish Time: 2025-03-04 Origin: Site

Content Menu

● Introduction to Aluminum Profiles

>> Key Features of Aluminum Profiles

● Applications of Aluminum Profiles

>> Solar Energy

● Customization of Aluminum Profiles

● Advantages of Using Aluminum Profiles

● Challenges and Future Developments

● Detailed Analysis of Aluminum Profile Applications

>> In-Depth Look at Construction

>> Emerging Trends in Furniture Design

● FAQs

>> 1. What are the primary industries that use aluminum profiles?

>> 2. What are the advantages of using aluminum profiles over steel?

>> 3. How are aluminum profiles customized for specific applications?

>> 4. What environmental benefits do aluminum profiles offer?

>> 5. What are some common types of aluminum profiles used in construction?

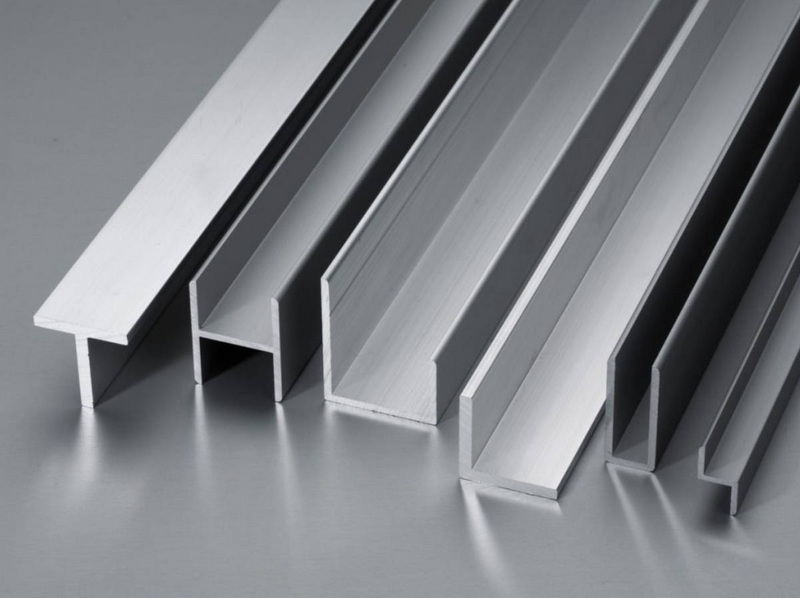

Aluminum profiles are versatile materials widely used across various industries due to their unique properties such as lightweight, durability, ease of processing, and recyclability. This article explores the diverse applications of aluminum profiles, highlighting their significance in construction, furniture, automotive, aerospace, and other sectors.

Aluminum profiles are extruded aluminum products that can be shaped into various forms and sizes, making them suitable for a wide range of applications. Their production involves the extrusion process, where aluminum is forced through a die to create the desired shape. This process allows for precise control over the dimensions and structure of the profiles, enabling them to be tailored for specific uses.

- Lightweight and Durable: Aluminum profiles are significantly lighter than steel while maintaining high strength, making them ideal for applications where weight reduction is crucial.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, enhancing its resistance to corrosion. This feature is particularly beneficial in environments with high humidity or exposure to corrosive substances.

- Ease of Processing: Aluminum can be easily cut, drilled, and shaped, allowing for flexible design options.

- Recyclability: Aluminum is highly recyclable, reducing waste and environmental impact.

In the construction sector, aluminum profiles are extensively used due to their durability and corrosion resistance. They are commonly found in:

- Door and Window Frames: Aluminum profiles provide a strong yet lightweight framework for doors and windows, enhancing structural integrity while reducing weight.

- Facade Cladding: Aluminum is used for exterior cladding of buildings, offering a durable and aesthetically pleasing finish.

- Roofing and Wall Systems: Aluminum profiles are used in roofing and wall systems for their strength and resistance to weather conditions.

- Balcony Railings and Sun Shades: These elements are often made from aluminum due to its durability and resistance to corrosion.

Aluminum profiles are integral in modern furniture design, particularly for minimalist and sleek aesthetics. They are used in:

- Table and Chair Legs: Providing stability and a modern look.

- Cabinet Doors and Drawers: Aluminum profiles offer durability and ease of maintenance.

- Shelves and Racks: Used for their strength and lightweight nature.

In the automotive sector, aluminum profiles help reduce vehicle weight, enhancing fuel efficiency and performance. They are used in:

- Chassis and Door Frames: Aluminum reduces weight while maintaining structural integrity.

- Engine Components: Aluminum is used for its thermal conductivity and lightweight properties.

- Interior Details: Such as seat frames and trim components.

The aerospace industry benefits from aluminum's high strength-to-weight ratio, making it ideal for aircraft and spacecraft components. Aluminum profiles are used in:

- Fuselage and Wing Structures: To achieve lightweight yet strong structures.

- Engine Mounts and Other Components: Where high strength and low weight are critical.

Aluminum profiles are used in solar panel frames and supports due to their durability and resistance to extreme weather conditions.

Aluminum's good thermal conductivity makes it suitable for heat sinks and enclosures in electronic devices.

The customization process for aluminum profiles involves several stages:

1. Design and Specification: Understanding the product parameters such as size, mechanical properties, and morphological structure.

2. Drawing and Confirmation: Creating detailed drawings and confirming them with clients.

3. Die Development: Producing dies that determine the profile's shape.

4. Sample Production: Extruding samples for approval before mass production.

- Cost-Effective: Aluminum profiles are generally less expensive than other materials like steel.

- Environmental Benefits: Highly recyclable, reducing waste and environmental impact.

- Aesthetic Appeal: Offers a modern and sleek appearance, suitable for various design needs.

Despite their advantages, aluminum profiles face challenges such as competition from other materials and the need for continuous innovation to meet evolving industry demands. Future developments are likely to focus on enhancing durability, improving manufacturing processes, and expanding into new sectors.

Beyond their use in doors and windows, aluminum profiles are also utilized in complex architectural designs. For instance, they are used in curtain wall systems, which provide a non-load-bearing exterior wall that covers the building's frame. This system allows for natural light penetration and offers a sleek, modern appearance.

In the automotive industry, the shift towards electric vehicles (EVs) has increased the demand for lightweight materials to enhance efficiency. Aluminum profiles play a crucial role in this transition by reducing vehicle weight, which in turn improves battery life and overall performance.

The aerospace industry continues to push the boundaries of aluminum profile applications. New alloys and manufacturing techniques are being developed to further reduce weight while maintaining strength, which is critical for achieving fuel efficiency and safety in aircraft.

In furniture design, aluminum profiles are increasingly used to create modular and sustainable pieces. This trend aligns with consumer preferences for eco-friendly products and flexible living spaces. Aluminum's recyclability and ease of processing make it an ideal material for this sector.

The global demand for aluminum profiles is influenced by factors such as technological advancements, environmental regulations, and economic conditions. As industries continue to seek sustainable and efficient materials, the market for aluminum profiles is expected to grow.

The emphasis on sustainability is driving innovation in aluminum profile production. Companies are focusing on reducing energy consumption during manufacturing and increasing the use of recycled aluminum. This not only reduces environmental impact but also lowers production costs.

Advancements in extrusion technology have improved the precision and efficiency of aluminum profile production. New machinery allows for more complex shapes and tighter tolerances, expanding the range of applications for aluminum profiles.

Aluminum profiles are versatile materials with a wide range of applications across multiple industries. Their unique combination of lightweight, durability, and ease of processing makes them an ideal choice for construction, furniture, automotive, aerospace, and other sectors. As technology advances, the use of aluminum profiles is expected to expand further, driven by their recyclability and environmental benefits.

- Aluminum profiles are used in construction, furniture, automotive, aerospace, and electronics industries.

- Aluminum profiles are lighter, more corrosion-resistant, and easier to process than steel.

- Customization involves detailed design, die development, sample production, and approval before mass production.

- Aluminum profiles are highly recyclable, reducing waste and environmental impact.

- Common types include anodized, powder-coated, and thermal break profiles, each offering different finishes and functionalities.

[1] https://patrop.com/usage-areas-of-aluminum-profiles-construction-furniture-automotive-and-more/

[2] https://www.gabrian.com/aluminium-extrusions/industries/

[3] https://haluminium.com/hoonly-aluminium-extrusion-profile-faq/

[4] https://www.sohu.com/a/415064276_727150

[5] https://www.mornglass.com/the-application-of-aluminium-profiles-in-building.html

[6] https://ba.zp-alluminio.com/info/applications-of-industrial-aluminum-profiles-81195800.html

[7] https://www.piometal.com/faq/

[8] https://blog.csdn.net/qq_34917728/article/details/125122327

[9] https://www.zahit.com.tr/what-is-aluminum-profile-what-are-its-usage-areas-and-features

[10] https://www.krcaluprofiles.com/tags/faqs-about-aluminum-profiles-for-cabinets-answered/

[11] https://www.disumtec.com/en/blog/23_.html

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden