English

Views: 222 Author: Astin Publish Time: 2025-04-25 Origin: Site

Content Menu

● Understanding Aluminum F Profiles

>> What Are Aluminum F Profiles?

>> Key Benefits

● Tools and Materials Required

● Step 1: Planning and Measuring

● Step 2: Cutting and Preparing Aluminum F Profiles

>> Wall and Ceiling Preparation

● Step 4: Fixing Aluminum F Profiles

>>> A. Mechanical Fixing (Screws/Brackets)

● Step 5: Installing Wall Panels or Ceiling Panels

● Common Mistakes and How to Avoid Them

● FAQs: Aluminum F Profile Installation

>> 1. What are the main applications of Aluminum F profiles?

>> 2. Can I install Aluminum F profiles by myself, or do I need a professional?

>> 3. How do I ensure a seamless joint at corners?

>> 4. What type of screws or fasteners should I use?

>> 5. How do I maintain and clean aluminum F profiles after installation?

Aluminum F profiles are essential elements in modern construction, offering both structural support and a sleek, finished look to wall panels and ceilings. Their lightweight, corrosion-resistant properties and ease of installation make them a preferred choice for both professionals and DIY enthusiasts. This comprehensive guide will walk you through every aspect of installing aluminum F profiles, from planning and preparation to expert finishing touches, ensuring your project achieves a professional, durable, and aesthetically pleasing result.

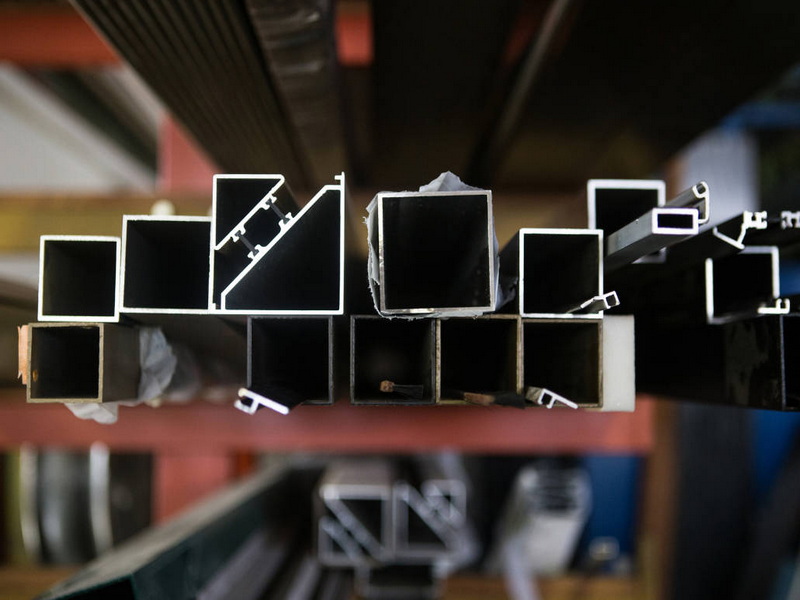

Aluminum F profiles are extruded sections with an "F" shaped cross-section, designed to provide edge finishing, support, and seamless transitions for wall panels and ceilings. Their unique shape allows them to cover panel edges, create neat terminations, and serve as connectors between different surfaces or materials. The F profile's versatility makes it suitable for suspended ceilings, partition walls, decorative trims, and even as channels for indirect lighting[2].

- Lightweight and Durable: Aluminum is naturally light yet strong, making F profiles easy to handle and long-lasting[2].

- Corrosion Resistant: Ideal for both interior and exterior applications, including humid or high-traffic areas[2][7].

- Aesthetic Versatility: Available in various finishes and sizes to match any design scheme[2].

- Easy to Cut and Shape: Can be cut to precise lengths and angles for custom installations[2][7].

Before starting your installation, gather the following tools and materials:

- Aluminum F profiles (pre-measured to fit your project)

- Measuring tape and pencil

- Level (laser or bubble)

- Fine-tooth hacksaw or miter saw (with metal-cutting blade)

- File or sandpaper (for smoothing edges)

- Mounting clips, brackets, or screws (stainless or acid-resistant recommended)[5]

- Drill and appropriate bits

- High-quality adhesive (construction adhesive or double-sided tape, if required)[2][4]

- End caps and corner connectors (if applicable)

- Safety equipment: gloves, safety glasses, dust mask

- Identify Installation Area: Determine whether the F profiles will be used for wall panels, ceiling panels, or both.

- Check Surface Conditions: Ensure surfaces are clean, dry, level, and free from dust, grease, or loose paint[4][7].

- Acclimate Materials: Allow aluminum profiles and panels to reach room temperature for at least 24 hours before installation, especially in climate-controlled environments[4].

- Measure Lengths and Angles: Use a tape measure and mark the installation lines with a pencil.

- Account for Expansion: Leave small gaps (typically 1/2 inch or 12 mm) at corners or between profiles to accommodate thermal expansion and structural movement[4][13].

- Dry-Fit Profiles: Lay out the profiles and panels without fixing them to ensure a perfect fit before permanent installation[7].

- Mark Cut Points: Clearly mark the required lengths on the profiles.

- Use the Right Tools: Cut with a fine-tooth hacksaw or a miter saw equipped with a metal-cutting blade for clean, precise cuts[2][8].

- Angle Cuts: For corners, cut at 45-degree angles to ensure a seamless joint, especially for frames or transitions[11].

- Smooth Edges: File or sand any rough edges to prevent injury and ensure a snug fit with panels and connectors[8][12].

- Install End Caps: Attach end caps to exposed ends for a finished look and to protect the profile and panel edges[8][12].

- Clean Thoroughly: Remove any dust, debris, or old adhesives from the installation surface[4][7].

- Level the Surface: Use a straight edge or level to check for flatness. Fill or sand any uneven areas as needed[7].

- Mark Mounting Points: Use a level to draw straight, even lines for profile placement, ensuring symmetry and alignment[8].

There are several methods to fix aluminum F profiles, depending on the surface and application:

- Pre-Drill Holes: Drill pilot holes in both the profile and the mounting surface to prevent splitting or misalignment[8][10].

- Use Appropriate Screws: Stainless steel or acid-resistant screws are best for durability and corrosion resistance[5].

- Secure with Mounting Clips/Brackets: Attach mounting clips or brackets to the surface, then snap or slide the F profile into place for a secure fit[8][12].

- Check Alignment: Use a level to ensure profiles are straight before fully tightening screws[11][15].

- Apply Adhesive: Use a high-quality construction adhesive or double-sided foam tape on the back of the profile[2][4].

- Position Carefully: Press the profile firmly against the marked line on the wall or ceiling. Adhesive bonds are usually permanent, so ensure correct placement before pressing[4].

- Temporary Support: Use small nails or clamps to hold the profile in place while the adhesive cures, if necessary[1].

- For added security, especially in high-traffic or load-bearing areas, use both screws and adhesive to fix the profiles[1][4].

- Start at Corners: Begin installation at inside or outside corners, working your way across the wall or ceiling[4][10].

- Leave Expansion Gaps: Maintain a 1/2 inch (13 mm) gap at corners and between panels to allow for movement[4][13].

- Align Panels: Use suction cup grabbers or clamps to hold panels in place while aligning with the F profiles and layout lines[4].

- Adhesive Application: Apply adhesive or foam tape to the back of panels as needed for additional hold[4].

- Mechanical Fastening: Where required, use screws or rivets to fix panels to the profiles, following manufacturer guidelines for spacing and placement[10][13].

- Overlay Edges: Overlap the flat edge of each panel over the recessed flange of adjacent panels for a seamless finish[4].

- Seal Joints: Use a low modulus, architectural-grade silicone sealant over backing rods to seal panel joints for moisture and air resistance[13].

- Smooth Sealant: Tool the sealant for a smooth, professional appearance.

- Check for Gaps or Misalignments: Ensure all profiles and panels are flush and level.

- Clean Surfaces: Wipe down profiles and panels to remove fingerprints, adhesive residue, or dust.

- Test Stability: Gently press on panels and profiles to ensure they are securely fixed.

- Regular Cleaning: Use a soft cloth and mild detergent to clean aluminum profiles and panels, avoiding abrasive materials that could scratch the finish[14].

- Inspect for Damage: Periodically check for loose screws, gaps, or signs of corrosion, especially in humid environments.

- Touch Up as Needed: Reapply sealant or touch up paint if necessary to maintain appearance and protection.

1. Incorrect Profile Selection: Always choose profiles suited for the environment (e.g., moisture-resistant for bathrooms)[7].

2. Poor Surface Preparation: Ensure surfaces are clean, dry, and level for optimal adhesion and alignment[7].

3. Inaccurate Cutting: Use precise measuring and cutting tools to avoid gaps or misaligned joints[7].

4. Improper Adhesive Use: Use adhesives compatible with both the surface and aluminum profile material[7].

5. Neglecting Expansion Gaps: Always allow for thermal expansion to prevent warping or buckling[13].

6. Skipping Dry Fit: Always dry-fit all profiles and panels before final installation to ensure a perfect fit[7].

Installing aluminum F profiles for wall panels or ceilings is a straightforward process that delivers professional, long-lasting results when executed with care and precision. By following the steps outlined in this guide—planning, measuring, cutting, preparing surfaces, fixing profiles, installing panels, and applying finishing touches—you can achieve a flawless installation that enhances both the structural integrity and visual appeal of your space.

Remember to avoid common mistakes by selecting the right materials, preparing surfaces meticulously, and allowing for expansion and movement. With regular maintenance, your aluminum F profile installation will remain durable and attractive for years to come.

Aluminum F profiles are commonly used for finishing and supporting wall panels, suspended ceilings, partition walls, and decorative trims. They are also popular in modern furniture and indirect lighting installations due to their versatility and aesthetic appeal[2][8].

While professional installation is recommended for large or complex projects, aluminum F profiles are designed for easy handling and can be installed by DIY enthusiasts with basic tools and careful planning[2][3][8].

For seamless corners, cut the F profiles at precise 45-degree angles using a miter saw. Dry-fit the pieces first, then secure them with screws or adhesive, ensuring the joints are tight and aligned[11].

Use stainless steel or acid-resistant screws for maximum durability, especially in humid or high-traffic areas. Pre-drill holes to prevent splitting and use mounting clips or brackets for additional support[5].

Clean aluminum profiles with a soft cloth and mild detergent. Avoid abrasive cleaners that could scratch the surface. Regularly check for loose fasteners or signs of corrosion and address any issues promptly to extend the lifespan of your installation[14].

[1] https://www.hugh-aluminum.com/how-to-install-the-aluminum-skirting/

[2] https://proaksmetal.com/f-profile/

[3] https://www.krcaluprofiles.com/blog/installing-aluminium-frame-profiles-a-step-by-step-guide/

[4] https://www.inprocorp.com/globalassets/resource-documents/aluminum-wall-panels_installation-instruction.pdf

[5] https://worldofaluminum.com/recommended/aluminum-profiles-shapes-application-and-installation/loue_xolg

[6] https://www.ifixit.com/Guide/Aluminum+Profile+Frame+Assembly/114729

[7] https://www.euroshrink.es/en/pl416/about-us/news/id22/common-mistakes-in-profile-installation-and-how-to-avoid-them.htm

[8] https://www.vst-lighting.com/how-to-install-aluminium-profiles-for-indirect-lighting/

[9] https://buildwell.in/common-mistakes-to-avoid-when-installing-a-false-ceiling/

[10] https://www.fibercementproducts.com/wp/wp-content/uploads/2018/09/Installation-Aluminum-2016-v2-1.pdf

[11] https://www.youtube.com/watch?v=dz_FRtB1_V4

[12] https://www.topledprofile.com/blog/a-step-by-step-guide-on-how-to-install-led-aluminum-profiles-230810c8-04eb-4951-a464-467a158c05d8

[13] https://tbafirefly.com.au/wp-content/uploads/2025/02/Solid-Aluminium-Cladding-Guide.pdf

[14] https://hplmachining.com/blog/what-are-the-problems-with-aluminum-extrusion/

[15] https://www.youtube.com/watch?v=BiN9wr3jzCk

[16] https://www.youtube.com/watch?v=zwM9pExzdxs

[17] https://www.tiktok.com/@skirtingline/video/7309012239896513797

[18] https://www.rollex.com/blog/how-to-install-aluminum-soffit-on-a-home/

[19] https://tbafirefly.com.au/wp-content/uploads/2025/02/Solid-Aluminium-Cladding-Guide.pdf

[20] https://www.youtube.com/watch?v=M9MVySYZILs

[21] https://www.rollex.com/blog/aluminum-soffit-porch-ceiling-installation-guide-tips/

[22] https://shop.machinemfg.com/how-to-join-aluminium-frame-a-step-by-step-guide/

[23] https://www.metlspan.com/wp-content/uploads/2022/11/CF-Vertical-Install-Guide.pdf

[24] https://www.gentek.ca/wp-content/uploads/sites/2/2021/01/Aluminum_Soffit_Fascia_And_Rainware_INSTALLATION-GUIDE_010213_ENG-1.pdf

[25] https://www.youtube.com/watch?v=saMzEP_oXGU

[26] https://www.mebel-alu.com/news/a-step-by-step-guide-to-installing-frame-aluminum-profiles/

[27] https://mcrma.co.uk/wp-content/uploads/2015/10/Best-Practice-for-Specification-of-Cladding-Secondary-Stee.pdf

[28] https://www.wb-aluminum.com/blog/faqs--common-questions-about-slim-profile-aluminium-sliding-doors

[29] https://www.tj-chinafreight.com/aluminum-window-profiles-the-ultimate-faq-guide/

[30] https://www.plasticsolutions.ie/products/aluminium-f-profile-brown-3m-10mm

[31] https://amberlinewindows.us/wp-content/uploads/2024/10/Manual-ALU-FULL-15-10-2024.pdf

[32] https://www.wellste.com/aluminium-profiles-for-windows-doors/

[33] https://norhageindustri.com/construction/aluminium-f-profile/

[34] https://www.tuli-shop.com/blog/aluminium-profile-load-capacity.html

[35] https://it.misumi-ec.com/files/images/products/docs/framingsupport.pdf

[36] https://my-floor.in/aluminium-profile/

[37] https://www.goldapple-alu.com/tips-for-troubleshooting-common-issues-with-aluminum-kitchen-profiles.html

[38] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[39] https://fonirteprofile.com/common_mistakes_in_aluminum_profile_production__insufficient_or_excessive_heat_treatment.html

[40] https://insights.made-in-china.com/Common-Failures-and-Preventive-Measures-of-Aluminum-Profile-Extrusion-Press-Machine_TAUaOMCJunHf.html

[41] https://hlled.com/how-to/aluminum-profile-thickness-for-outdoor/

[42] https://www.bwcprofiles.co.uk/extrusion-academy/profile-design-5-common-mistakes

[43] https://www.reddit.com/r/simracing/comments/191tj2z/aluminum_frame_up_rights_too_high/

[44] https://www.zmartbuild.com/5-most-common-drywall-installation-mistakes/

[45] https://www.sciencedirect.com/topics/engineering/aluminum-profile

[46] https://www.alibaba.com/product-detail/All-collection-Stretch-ceiling-film-installation_60781051207.html

[47] https://www.hettich.com/fileadmin/Media_Center/Catalogue/Aluminum_profile_Catalogue_Apr_2021.pdf

[48] https://kingornan.com/led-aluminium-profile-guide-2022/

[49] https://www.guangyaaluminium.com/several-common-aluminum-profile-extrusion-die-problems-and-repair-methods_n150

[50] https://www.linkedin.com/pulse/common-problems-causes-aluminum-profiles-fenan-aluminum-co-ltd

[51] https://prospacehome.com/installation-guide-and-selection-tips-for-aluminium-windows/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden