English

Views: 222 Author: Astin Publish Time: 2025-04-21 Origin: Site

Content Menu

● Understanding Aluminum Extrusion Profiles

● Why Choosing the Right Supplier Matters

● Key Factors to Evaluate When Searching for Suppliers

>> 1. Supplier Experience and Expertise

>> 2. Product Quality and Certification

>> 3. Manufacturing Capabilities and Technology

>> 4. Range of Products and Customization

>> 5. Customer Service and Communication

>> 6. Delivery Times and Logistics

>> 7. Competitive and Transparent Pricing

>> 8. Reputation and References

● Step-By-Step Guide to Finding a Reliable Aluminum Extrusion Profiles Supplier

>> Step 1: Define Your Requirements

>> Step 2: Research Potential Suppliers

>> Step 3: Evaluate Capabilities and Experience

>> Step 4: Request Samples and Visit Facilities

>> Step 5: Assess Quality Assurance and Certifications

>> Step 6: Compare Pricing and Lead Times

>> Step 7: Check References and Reviews

>> Step 8: Negotiate Terms and Build a Relationship

● The Importance of a Long-Term Supplier Relationship

● Frequently Asked Questions (FAQ)

>> 1. What certifications should a reliable aluminum extrusion profile supplier have?

>> 2. How can I verify the quality of a supplier's aluminum extrusion profiles?

>> 3. What should I look for in a supplier's customer service?

>> 4. How do I ensure timely delivery of my aluminum extrusion profiles?

>> 5. Is it better to choose a local or international supplier?

Aluminum extrusion profiles are foundational elements in modern manufacturing, construction, automotive, and countless other industries. The demand for precision, durability, and customization has made the search for reliable aluminum extrusion profile suppliers more critical than ever. However, with a crowded marketplace and varying standards, identifying a trustworthy supplier can be daunting. This comprehensive guide will walk you through the essential steps, criteria, and strategies for finding a supplier you can count on for quality, service, and long-term partnership.

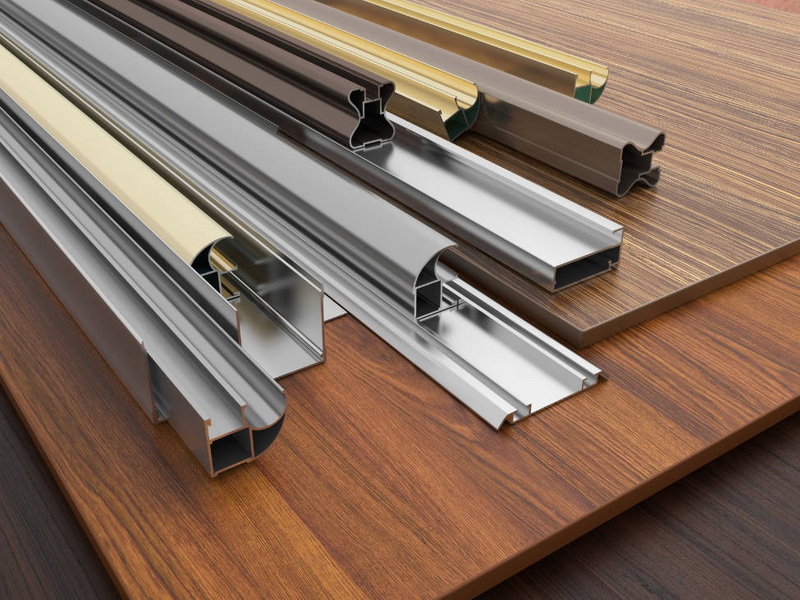

Aluminum extrusion is a process where aluminum alloy material is forced through a die with a specific cross-sectional profile. The resulting profiles are used in everything from window frames and structural supports to automotive parts and consumer electronics. The versatility, lightweight nature, and corrosion resistance of aluminum make it an ideal choice for a wide range of applications.

High-quality aluminum extrusion profiles are crucial for ensuring the strength, durability, and precision of your final products. Whether you are working on a small-scale DIY project or a massive industrial undertaking, the right supplier will have a direct impact on your project's success[1].

Selecting a reliable supplier is about more than just sourcing material. The right partner ensures:

- Consistent product quality

- On-time delivery

- Technical support and customization

- Competitive pricing

- Long-term business growth

A poor supplier, on the other hand, can lead to production delays, quality issues, increased costs, and reputational damage[2].

- Look for suppliers with a proven track record in aluminum extrusion manufacturing.

- Experience in your specific industry (e.g., automotive, construction, electronics) is a plus.

- Experienced suppliers are more likely to offer valuable guidance and handle complex, custom requirements[1][2][3].

- Quality should be non-negotiable. Insist on suppliers with strict quality control standards and relevant certifications (such as ISO 9001).

- Ask about their quality assurance processes, inspection routines, and whether they provide test reports or certificates of conformity[2][3].

- Assess whether the supplier has the equipment and technology to produce profiles to your exact specifications.

- Modern, well-equipped facilities are more likely to deliver precision and handle large or custom orders efficiently[1][4].

- A good supplier should offer a wide variety of standard profiles and the flexibility to create custom solutions.

- This ensures they can meet both current and future needs as your business evolves[1].

- Responsive, knowledgeable customer service is vital for smooth project execution.

- Evaluate how quickly they respond to inquiries, their willingness to provide technical support, and their transparency during the quoting and production process[2].

- Timely delivery is crucial for keeping your project on schedule.

- Assess the supplier's production capacity, lead times, and logistics capabilities to ensure they can meet your deadlines[2].

- Compare quotes from multiple suppliers, but beware of prices that seem too good to be true.

- Ensure all costs are transparent and there are no hidden fees that could inflate your budget later[1][2].

- Check online reviews, testimonials, and case studies.

- Ask for references or examples of past projects similar to yours.

- A strong reputation is a good indicator of reliability and customer satisfaction[1][2][3].

- Specify the type, size, and quantity of profiles needed.

- Clarify tolerances, surface finishes, and any special requirements (e.g., anodizing, powder coating).

- Use online directories, industry events, and referrals to compile a list of candidates.

- Review their websites, product catalogs, and case studies to assess their capabilities[1][2].

- Shortlist suppliers with relevant industry experience and technical expertise.

- Confirm they can handle your volume and complexity requirements[1][3][4].

- Ask for product samples to assess quality firsthand.

- If possible, visit their manufacturing facilities to evaluate equipment, processes, and cleanliness[2].

- Verify their quality management systems and certifications.

- Inquire about inspection procedures and whether they offer traceability for materials used[3].

- Request detailed quotes with clear breakdowns of costs.

- Discuss lead times and ensure they align with your project schedule[1][2].

- Contact previous clients for feedback on reliability, quality, and service.

- Look for patterns in reviews that indicate strengths or recurring issues[2][3].

- Clarify payment terms, warranties, and after-sales support.

- Establish clear communication channels and expectations for ongoing collaboration[1].

- Lack of certifications or unwillingness to provide documentation

- Poor communication or slow response times

- Unclear pricing structures or hidden fees

- Negative reviews or unresolved complaints

- Limited product range or inability to meet customization needs

Building a strong partnership with your aluminum extrusion profile supplier delivers several benefits:

- Consistent quality and reliable deliveries

- Access to technical expertise and innovation

- Better pricing through volume and loyalty

- Flexibility to accommodate urgent or custom orders[1]

A long-term relationship also means your supplier understands your business and can proactively suggest improvements or new solutions as your needs evolve.

Finding a reliable aluminum extrusion profiles supplier is a critical step that can determine the success or failure of your project. By focusing on supplier experience, product quality, manufacturing capabilities, customer service, and reputation, you can minimize risks and build a partnership that supports your business for years to come. Take the time to research, compare, and communicate clearly with potential suppliers. Remember, the right supplier is not just a vendor—they are a strategic partner in your success.

A trustworthy supplier should hold certifications like ISO 9001 for quality management and, depending on your industry, additional standards such as ISO 14001 for environmental management. These certifications demonstrate a commitment to quality and continuous improvement[3].

You can request samples, review quality control documentation, and ask about their inspection processes. Visiting the supplier's facility or arranging for a third-party audit can also provide assurance of their quality standards[2][3].

Look for responsiveness, clear communication, technical support, and a willingness to address your concerns promptly. Good customer service ensures smoother project execution and quick resolution of any issues that arise[1][2].

Assess the supplier's production capacity, logistics network, and track record for meeting deadlines. Discuss lead times upfront and include penalties for late deliveries in your contract if necessary[2].

Both options have pros and cons. Local suppliers may offer faster delivery and easier communication, while international suppliers might provide cost advantages or specialized capabilities. Consider your project's priorities—speed, cost, customization, or scale—when making this decision.

[1] https://www.szsunqit.com/a-the-ultimate-guide-to-finding-the-best-aluminum-extrusion-profile-supplier.html

[2] https://www.yuhfield.net/en/news/aluminum-extrusion/reliable-custom-aluminum-extrusion-suppliers

[3] https://americandouglasmetals.com/2023/10/03/key-considerations-in-selecting-an-aluminum-extrusions-profiles-provider/

[4] https://jmaluminium.com/choosing-an-aluminum-extrusion-manufacturer-what-to-consider-when-researching-a-partner/

[5] https://www.reddit.com/r/manufacturing/comments/uc2prf/can_anybody_recommend_an_aluminum_extrusion/

[6] https://profileprecisionextrusions.com/finding-the-best-aluminum-extrusion-partner-for-your-project/

[7] https://www.profall.com/en/blog/profall-worldwide-aluminum-extrusion-suppliers

[8] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-aluminum-extrusion-suppliers-in-the-usa/

[9] https://www.tslots.com

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden