English

Views: 222 Author: Astin Publish Time: 2025-05-07 Origin: Site

Content Menu

● Understanding Aluminum Louvers

● Key Factors to Consider When Choosing an Aluminum Louver Profile

>> 2. Airflow Direction and Volume

>> 3. Blade Type, Angle, and Spacing

>> 8. Maintenance and Longevity

● Types of Aluminum Louvers for Ventilation

>> Adjustable Aluminum Louvers

>> Architectural Aluminum Louvers

>> Storm-Resistant and Drainable Louvers

● Applications of Aluminum Louvers

● Practical Tips for Selecting the Right Aluminum Louver Profile

● Advanced Considerations for Aluminum Louvers

>> Integration with Building Automation Systems

>> Environmental Impact and Sustainability

>> Customization and Design Trends

>> Installation and Compliance

● FAQ

>> 1. What are the main types of aluminum louvers used for ventilation?

>> 2. How does blade angle affect louver performance?

>> 3. Why is aluminum preferred over other materials for louvers?

>> 4. How do I determine the correct louver depth?

>> 5. Can aluminum louvers help reduce energy costs?

Choosing the right aluminum louver profile for ventilation is a critical decision that impacts airflow efficiency, weather protection, aesthetic appeal, and overall building performance. Aluminum louvers are widely favored due to their durability, lightweight nature, corrosion resistance, and design flexibility. This comprehensive guide will walk you through the key considerations, types, and applications of aluminum louvers to help you make an informed choice.

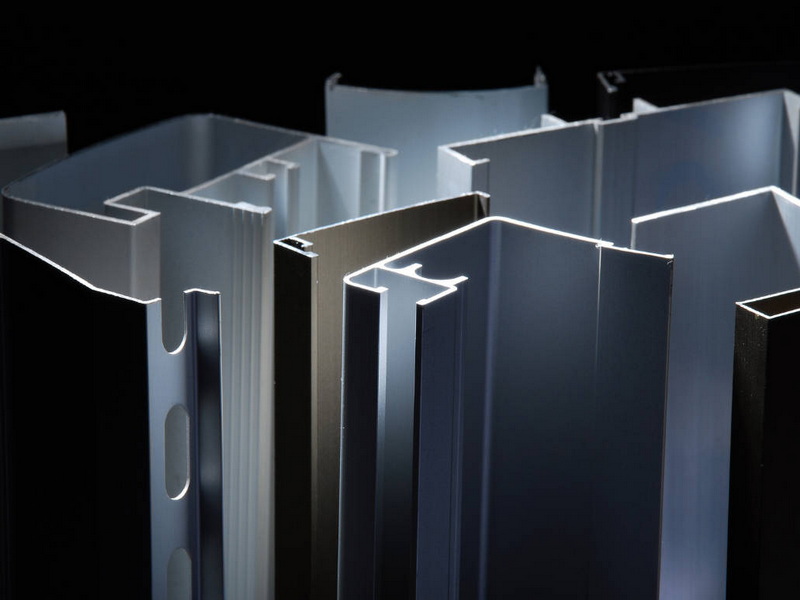

Aluminum louvers are slatted structures designed to regulate airflow, light, and protection from environmental elements. They are commonly used in commercial, industrial, and residential buildings for ventilation, sun shading, and architectural enhancement.

- Durability and Weather Resistance: Aluminum resists corrosion and rust, making it ideal for outdoor and harsh environments.

- Lightweight: Easier to handle and install compared to heavier metals.

- Customizable: Can be tailored in size, shape, color, and finish to suit specific design and functional needs.

- Low Maintenance: Requires minimal upkeep and is easy to clean.

- Energy Efficiency: Helps control airflow and light, reducing HVAC loads and energy consumption.

- Eco-Friendly: Aluminum is fully recyclable, supporting sustainable building practices.

Identify the primary function of the louver:

- Ventilation (intake or exhaust)

- Protection from rain and debris

- Noise reduction (acoustic louvers)

- Sun shading

- Architectural aesthetics

- Storm resistance

Knowing the application helps prioritize features like airflow, weather protection, or sound attenuation.

Determine whether the louver will serve as an intake or exhaust point. This affects blade orientation and design. Also, calculate the air volume (CFM) and face velocity (FPM) to ensure the louver can handle the required airflow without excessive pressure drop.

- Blade Angle: Larger angles improve rain protection but increase airflow resistance.

- Blade Spacing: Wider spacing increases free area for airflow but may reduce protection.

- Blade Type: Fixed blades are common for consistent airflow; adjustable blades allow control over ventilation and light.

The depth of the louver frame should match the wall or opening thickness for proper installation and structural support. Deeper louvers enhance rain protection but may cost more and require additional support.

Extruded aluminum is preferred for its lightweight and corrosion resistance. Finishes can include powder coating or anodizing to enhance durability and aesthetics.

Choose louvers with features like twin weather stops, drainable designs, or storm-resistant construction if the location is prone to heavy rain, wind-driven rain, or storms.

For noisy environments, select acoustic aluminum louvers designed to reduce sound transmission while maintaining airflow.

Aluminum louvers require less maintenance than steel alternatives and resist rust and corrosion, ensuring long-term performance.

- Blades are stationary.

- Provide consistent airflow and protection.

- Common in HVAC systems and general ventilation.

- Offer good rain defense with appropriate blade design.

- Blades can be manually or electronically operated.

- Allow control over airflow and light.

- Ideal for spaces requiring variable ventilation or privacy.

- Custom-designed for aesthetic integration.

- Available in various shapes, sizes, and colors.

- Enhance building facades while providing ventilation.

- Designed to reduce noise while allowing airflow.

- Used in industrial, urban, or transportation environments.

- Built to withstand severe weather conditions.

- Include features to divert rainwater and resist wind-driven rain.

- Integrated into building exteriors for minimal visual impact.

- Provide ventilation without compromising design.

- Commercial Buildings: HVAC protection, energy efficiency, and facade enhancement.

- Industrial Facilities: Airflow management, noise reduction, and equipment protection.

- Residential Buildings: Privacy, ventilation, and weather protection.

- Coastal and Storm-Prone Areas: Enhanced durability against harsh weather.

- Architectural Projects: Custom designs for aesthetic and functional needs.

- Match louver depth to wall thickness to avoid installation issues.

- Balance blade angle and spacing to optimize airflow and weather protection.

- Consider the environment-choose storm-resistant louvers for harsh climates.

- Factor in maintenance requirements and lifecycle costs.

- Consult with manufacturers for customization options and performance data.

- Use insect or bird screens if the area is prone to pests.

Aluminum louvers can influence the thermal performance of a building. By controlling the amount of sunlight and airflow, louvers help in reducing heat gain during summer and heat loss during winter. Selecting louvers with appropriate blade design and finish can enhance energy efficiency by minimizing the need for artificial heating and cooling.

Modern adjustable aluminum louvers can be integrated with building automation systems (BAS) to optimize ventilation based on real-time environmental data. Sensors can control blade angles automatically to maintain indoor air quality, temperature, and humidity, improving occupant comfort and reducing energy costs.

Aluminum is a highly recyclable material, and many manufacturers use recycled aluminum in their products. Choosing aluminum louvers supports sustainable building practices. Additionally, louvers that improve natural ventilation reduce reliance on mechanical HVAC systems, lowering carbon footprints.

Architectural trends increasingly favor louvers as design elements. Custom shapes, colors, and finishes allow architects to create visually striking facades. Perforated or patterned louvers can add artistic flair while maintaining functionality.

Proper installation is crucial for louver performance. It is important to follow manufacturer guidelines and local building codes. Compliance with standards such as AMCA (Air Movement and Control Association) ensures louvers meet performance criteria for airflow and weather resistance.

Regular inspection and cleaning extend the life of aluminum louvers. Removing debris, checking for damage, and ensuring moving parts are lubricated help maintain optimal function. Powder-coated finishes may require touch-ups to prevent corrosion.

A commercial office building in a coastal city installed storm-resistant aluminum louvers with powder-coated finishes. The louvers provided excellent protection against salt spray and heavy rain while enhancing the building's modern aesthetic.

An industrial facility used acoustic aluminum louvers to reduce noise pollution from machinery. The louvers effectively minimized sound transmission without compromising ventilation, improving worker comfort.

A residential complex incorporated adjustable aluminum louvers on balconies to provide privacy and control sunlight. Residents appreciated the ability to adjust airflow and shading according to their preferences.

Emerging technologies in aluminum louvers include smart materials that change properties based on environmental conditions, and integration with renewable energy systems such as solar panels. These innovations promise to further enhance building performance and sustainability.

Selecting the right aluminum louver profile for ventilation requires a careful assessment of the intended application, airflow requirements, environmental conditions, and aesthetic goals. Aluminum louvers offer unmatched versatility, combining durability, lightweight construction, and design flexibility. By understanding the different types of louvers and their specific features, you can optimize ventilation performance while enhancing building appearance and longevity. Whether for commercial, industrial, or residential use, aluminum louvers provide an effective, low-maintenance solution that supports energy efficiency and sustainable building practices.

The main types include fixed louvers for constant airflow, adjustable louvers for variable control, architectural louvers for design integration, acoustic louvers for noise reduction, and storm-resistant louvers for harsh weather protection.

A larger blade angle improves rain and debris protection but increases resistance to airflow, potentially reducing ventilation efficiency.

Aluminum is lightweight, corrosion-resistant, durable, customizable, low maintenance, and eco-friendly, making it ideal for various ventilation applications.

The louver depth should closely match the thickness of the wall or opening where it will be installed to ensure proper fit and support.

Yes, by improving natural ventilation and controlling airflow, aluminum louvers reduce the load on HVAC systems, leading to lower energy consumption.

Top Aluminum Profiles Manufacturers and Suppliers in Czech Republic

Top Aluminum Profiles Manufacturers and Suppliers in Belgium

Top Aluminum Profiles Manufacturers and Suppliers in Finland

Top Aluminum Profiles Manufacturers and Suppliers in Denmark

Top Aluminum Profiles Manufacturers and Suppliers in Portugal