English

Views: 222 Author: Astin Publish Time: 2025-03-04 Origin: Site

Content Menu

● Introduction to Extruded Aluminum Profiles

>> Key Characteristics of Extruded Aluminum Profiles

● Applications of Extruded Aluminum Profiles

>> 1. Structural Frameworks and Architecture

>> 4. Balustrades and Railings

>> 5. Renewable Energy Solutions

>> 6. Automotive and Aerospace

● Design Considerations for Extruded Aluminum Profiles

● Steps in the Aluminum Extrusion Process

● Choosing the Best Extruded Aluminum Profiles

>> Advanced Manufacturing Techniques

>> Collaboration with Manufacturers

● Case Studies: Successful Applications of Extruded Aluminum Profiles

>> 1. Modular Building Construction

>> 2. Solar Panel Mounting Systems

>> 3. Automotive Lightweighting

● FAQ

>> 1. What are the primary benefits of using extruded aluminum profiles in construction?

>> 2. How do extruded aluminum profiles contribute to sustainable architecture?

>> 3. What are the common surface treatments for extruded aluminum profiles?

>> 4. Can extruded aluminum profiles be used in high-temperature applications?

>> 5. How do extruded aluminum profiles support renewable energy solutions?

Choosing the right extruded aluminum profiles for your project can be a daunting task, especially with the vast array of options available in the market. Extruded aluminum profiles are widely used across various industries, including architecture, automotive, electronics, and renewable energy, due to their versatility, durability, and sustainability. This article aims to guide you through the process of selecting the best extruded aluminum profiles for your specific needs.

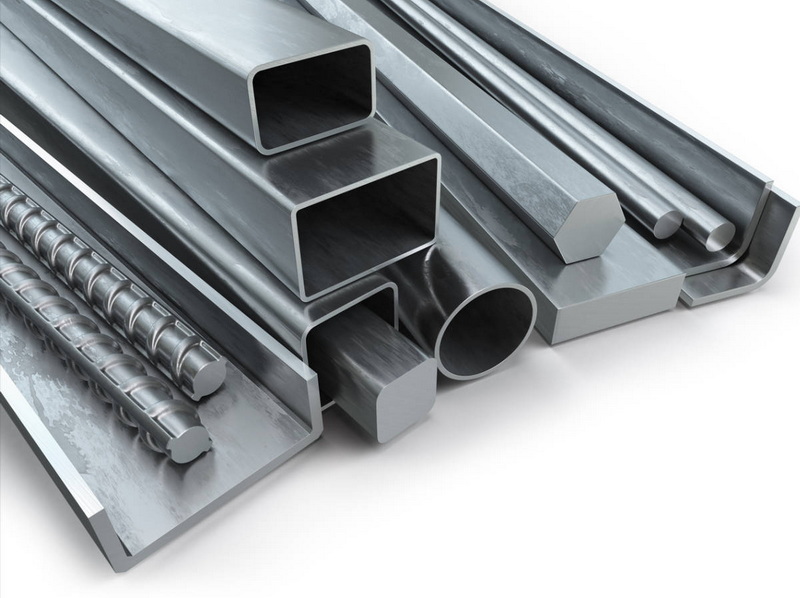

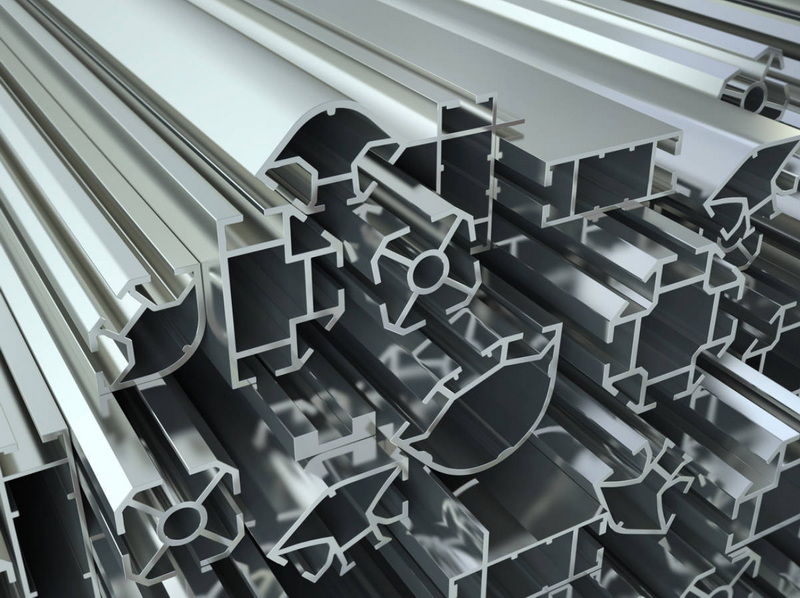

Extruded aluminum profiles are created through a process where aluminum alloy is forced through a die to achieve a desired shape. This process allows for the creation of complex profiles with precise dimensions, making them ideal for applications requiring both strength and lightweight properties. The versatility of extruded aluminum profiles is evident in their use in structural frameworks, curtain wall systems, doors and windows, balustrades, and even solar panel mounting systems.

- Strength-to-Weight Ratio: One of the most significant advantages of extruded aluminum profiles is their high strength-to-weight ratio, making them perfect for applications where minimizing weight without compromising structural integrity is crucial.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which provides excellent resistance to corrosion, especially when further enhanced by surface treatments like anodizing or powder coating.

- Thermal Insulation: Extruded aluminum profiles can be designed to offer superior thermal insulation, reducing heat transfer and improving energy efficiency in buildings.

- Sustainability: Aluminum is highly recyclable, making extruded aluminum profiles a sustainable choice for environmentally conscious projects.

In modern architecture, extruded aluminum profiles are used extensively for structural frameworks due to their lightweight yet robust nature. They are ideal for modular building designs, facades, and partitions, allowing for easy assembly and modification. This flexibility is particularly beneficial in temporary or movable structures, such as exhibition stands or pop-up shops.

High-rise buildings often utilize extruded aluminum profiles in curtain wall systems for their sleek appearance and excellent weather resistance. These systems provide thermal insulation and contribute to sustainable building practices by reducing energy consumption. Additionally, they offer a wide range of design possibilities, from minimalist to elaborate facades.

The use of extruded aluminum profiles in door and window frames is widespread due to their durability and minimal maintenance requirements. They offer superior thermal insulation, enhancing energy efficiency in both residential and commercial settings. Furthermore, their corrosion resistance ensures that they remain functional and aesthetically pleasing over time.

For balustrades and railings, extruded aluminum profiles are preferred for their strength and corrosion resistance. They provide both safety and aesthetic appeal, making them suitable for staircases, balconies, and terraces. The sleek design of aluminum balustrades can enhance the visual appeal of any space, from modern homes to public buildings.

In the renewable energy sector, extruded aluminum profiles play a crucial role in solar panel mounting systems. Their lightweight and corrosion-resistant properties ensure secure support for solar panels, optimizing energy capture. Additionally, they are used in wind turbines for similar reasons, providing structural support while minimizing weight.

In the automotive and aerospace industries, extruded aluminum profiles are used to create lightweight yet strong components. This reduces overall vehicle weight, improving fuel efficiency and performance. In aerospace, these profiles contribute to the structural integrity of aircraft while maintaining minimal weight, which is critical for fuel efficiency and safety.

When designing with extruded aluminum profiles, several factors must be considered to ensure optimal performance and cost efficiency:

- Wall Thickness: The choice of wall thickness depends on the required strength and cost targets. Uniform wall thickness is easier to produce, but variations can be made if necessary.

- Shape and Corners: Rounded shapes and corners are recommended as they improve the design's structural integrity and ease of production. Sharp corners can be achieved with additional machining.

- Surface Treatment: Surface treatments like anodizing or powder coating can enhance appearance and corrosion resistance.

- Material Selection: Different aluminum alloys offer varying mechanical properties. For instance, 6063 is commonly used for architectural applications due to its excellent corrosion resistance and surface finish, while 6061 is preferred for structural applications requiring higher strength.

Understanding the aluminum extrusion process can help in selecting the right profiles for your project:

1. Billet Preparation: The aluminum billet is preheated to a specific temperature.

2. Extrusion: The heated billet is forced through a die to form the desired profile.

3. Cooling: The extruded profile is cooled using air or water quenching.

4. Stretching and Straightening: Some profiles undergo stretching to align molecules and reduce internal stresses.

5. Cutting to Length: Profiles are cut to desired lengths.

6. Surface Treatment: Optional surface treatments are applied for enhanced appearance and durability.

To choose the best extruded aluminum profiles for your project, consider the following:

- Application Requirements: Determine the specific needs of your project, such as structural support, thermal insulation, or corrosion resistance.

- Material Properties: Select an aluminum alloy that meets your project's mechanical and chemical requirements.

- Design Flexibility: Ensure the profile design is feasible for extrusion and meets your project's specifications.

- Cost and Sustainability: Consider the cost-effectiveness and environmental impact of the profiles.

Modern manufacturing techniques have further enhanced the capabilities of extruded aluminum profiles. For instance, advanced extrusion processes allow for the creation of complex shapes with multiple cavities, improving structural efficiency. Additionally, technologies like 3D printing can be used to create custom connectors or fittings for aluminum profiles, offering greater design flexibility.

Collaborating closely with manufacturers is crucial for optimizing the design and production of extruded aluminum profiles. Manufacturers can provide insights into the feasibility of specific designs and suggest modifications to improve production efficiency and reduce costs. This collaboration ensures that the final product meets both functional and aesthetic requirements.

A recent project in modular building construction utilized extruded aluminum profiles to create a fully modular, easily transportable structure. The use of aluminum profiles allowed for rapid assembly and disassembly, making it ideal for temporary or emergency housing solutions.

In a large-scale solar farm project, extruded aluminum profiles were used to create mounting systems for solar panels. The lightweight yet robust nature of these profiles ensured secure support for the panels while minimizing material usage, thereby reducing overall project costs.

In the automotive sector, a leading manufacturer used extruded aluminum profiles to create lightweight components for electric vehicles. This not only improved fuel efficiency but also enhanced the overall performance of the vehicles.

Selecting the right extruded aluminum profiles for your project involves understanding their applications, design considerations, and the extrusion process itself. By considering factors such as strength, corrosion resistance, thermal insulation, and sustainability, you can ensure that your project benefits from the versatility and durability of extruded aluminum profiles.

- The primary benefits include their high strength-to-weight ratio, corrosion resistance, and ease of assembly, making them ideal for structural frameworks and modular designs.

- They contribute by being lightweight, recyclable, and offering excellent thermal insulation, which reduces energy consumption and supports environmentally friendly building practices.

- Common surface treatments include anodizing, powder coating, and painting, which enhance appearance and corrosion resistance.

- While aluminum generally has a lower melting point, certain alloys can be used in high-temperature applications with appropriate heat treatment and design considerations.

- They provide strong, lightweight, and corrosion-resistant support for solar panels and wind turbines, optimizing energy capture and ensuring durability in harsh environmental conditions.

[1] https://www.tuli-shop.com/blog/aluminum-extrusion-and-applications-guide.html

[2] https://8020.com.au/article/8-applications-of-aluminium-extrusion-in-modern-architecture/

[3] https://pmc.ncbi.nlm.nih.gov/articles/PMC8967828/

[4] https://waykenrm.com/blogs/aluminum-extrusion/

[5] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-applications-of-aluminum-extrusion-profiles-in-various-industries/

[6] https://pmc.ncbi.nlm.nih.gov/articles/PMC8911382/

[7] https://www.shapesbyhydro.com/en/design-thinking/extrusion-quick-guide-for-designing-with-aluminium/

[8] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[9] https://patents.google.com/patent/US20080127701A1/en

[10] https://www.richardsonmetals.com/resources/aluminum-extrusions-guide/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden