English

Views: 222 Author: Astin Publish Time: 2025-03-19 Origin: Site

Content Menu

● Introduction to Aluminum and Steel

● Applications of Aluminum and Steel

● Design and Manufacturing Considerations

● Challenges and Future Developments

● FAQs

>> 1. What is the primary advantage of using aluminum over steel in construction?

>> 2. How does the tensile strength of aluminum compare to that of steel?

>> 3. What are the common applications of aluminum extrusions?

>> 4. How does the cost of aluminum compare to that of steel?

>> 5. What are the environmental benefits of using aluminum?

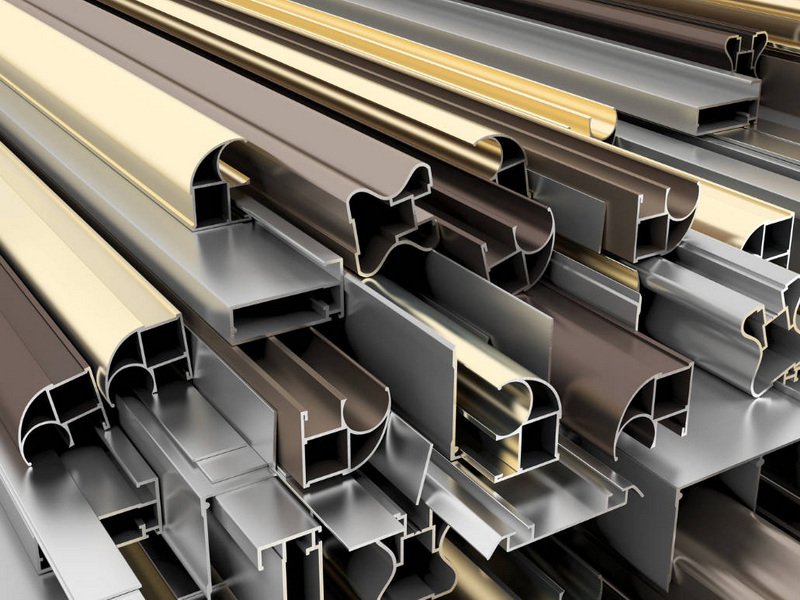

In the world of engineering and construction, the choice between aluminum and steel is often a critical one. Both materials have unique properties that make them suitable for different applications. Aluminum profile extrusions, in particular, have gained popularity due to their versatility, lightweight nature, and corrosion resistance. However, when it comes to raw strength, steel generally outperforms aluminum. This article will delve into the strengths and weaknesses of both materials, exploring their applications, advantages, and limitations.

Aluminum and steel are two of the most widely used metals in modern industry. Aluminum is known for its lightweight, corrosion-resistant properties, making it ideal for applications where weight reduction is crucial, such as in aerospace and automotive manufacturing. Steel, on the other hand, is renowned for its strength and durability, making it a staple in construction and heavy machinery.

Aluminum is a non-ferrous metal that is abundant in nature. It is highly malleable and ductile, allowing it to be easily shaped into various forms without breaking. Aluminum naturally forms a protective oxide layer when exposed to air, which provides excellent corrosion resistance. This property makes aluminum a preferred choice for outdoor and marine applications.

One of the most significant advantages of aluminum is its strength-to-weight ratio. Although it has a lower tensile strength compared to steel, aluminum's lightweight nature means that it can provide comparable structural integrity while weighing significantly less. For instance, aluminum alloy 6005-T5 has a tensile strength of about 37,700 psi, while steel can have tensile strengths ranging from 50,000 to over 100,000 psi depending on the type.

Steel is an alloy of iron and carbon, with varying carbon content affecting its strength, hardness, and ductility. It is denser and heavier than aluminum, making it more suitable for applications requiring high strength and durability. Steel is widely used in construction, machinery, and transportation due to its ability to withstand heavy loads and resist deformation.

Steel also has a higher melting point than aluminum, which makes it more resistant to high temperatures. However, steel can corrode if not properly coated or treated, unlike aluminum, which naturally resists corrosion.

Both aluminum and steel have diverse applications across various industries.

1. Aerospace and Automotive: Aluminum is extensively used in aircraft and vehicle bodies due to its lightweight nature, which enhances fuel efficiency and performance.

2. Construction: Aluminum extrusions are used in architectural features like window frames, curtain walls, and railings due to their corrosion resistance and versatility.

3. Electronics: Aluminum's high thermal conductivity makes it suitable for heat sinks and other electronic components.

4. Marine and Outdoor: Its corrosion resistance makes aluminum ideal for marine environments and outdoor furniture.

1. Construction: Steel is a primary material in building frameworks, bridges, and skyscrapers due to its high strength and durability.

2. Machinery and Equipment: Steel is used in manufacturing machinery, tools, and equipment because of its robustness and ability to withstand heavy use.

3. Transportation: Steel is used in vehicle manufacturing, including cars, trains, and ships, due to its strength and durability.

4. Aerospace: Certain steel alloys are used in critical aerospace components where high strength is essential.

When comparing the strength of aluminum and steel, several factors come into play:

- Tensile Strength: Steel generally has a higher tensile strength than aluminum. For example, mild steel can have a tensile strength of about 55,000 psi, while aluminum alloy 6005-T5 has a tensile strength of approximately 37,700 psi.

- Strength-to-Weight Ratio: Aluminum has a better strength-to-weight ratio than steel, making it more efficient for applications where weight reduction is critical.

- Corrosion Resistance: Aluminum naturally resists corrosion, while steel requires additional coatings or treatments to achieve similar resistance.

The cost of aluminum and steel can vary based on market conditions and specific alloys. Generally, steel is cheaper by weight than aluminum, although certain types of stainless steel can be comparable in price to aluminum alloys.

In terms of sustainability, both metals are recyclable, but aluminum requires less energy to recycle than steel. This makes aluminum a more environmentally friendly option for applications where recycling is a consideration.

When designing with aluminum or steel, several manufacturing considerations come into play:

- Fabrication Techniques: Aluminum can be easily extruded, cast, or machined, while steel is often welded or forged. The choice of fabrication technique can significantly impact the final product's strength and durability.

- Material Selection: Choosing the right alloy is crucial. For aluminum, alloys like 6061-T6 and 6005-T5 are popular for structural applications, while for steel, the choice often depends on the required strength and corrosion resistance.

- Surface Treatment: Aluminum often requires no additional surface treatment due to its natural corrosion resistance, while steel may need coatings or galvanization to protect against corrosion.

Both aluminum and steel are being used in innovative ways to meet modern challenges:

- Sustainable Buildings: Aluminum is used in green buildings for its recyclability and energy efficiency, while steel is used for its strength and ability to support large structures.

- Electric Vehicles: Aluminum is increasingly used in electric vehicles to reduce weight and enhance efficiency, while steel remains a primary material for structural components.

- Renewable Energy: Aluminum is used in wind turbines and solar panels due to its lightweight and corrosion-resistant properties, while steel is used for the structural support of these systems.

As technology advances, both aluminum and steel face challenges and opportunities:

- Material Development: Researchers are continually developing new alloys with improved properties. For example, advanced high-strength steels (AHSS) offer improved strength and formability, while new aluminum alloys are being developed for aerospace applications.

- Sustainability: The focus on sustainability is driving innovations in recycling and production processes. Aluminum, in particular, benefits from its high recyclability and lower energy requirements for recycling.

- Technological Integration: The integration of materials with advanced technologies, such as 3D printing and smart materials, is opening new possibilities for both aluminum and steel in complex applications.

In conclusion, while steel outperforms aluminum in terms of raw strength, aluminum's lightweight nature and corrosion resistance make it an ideal choice for applications where these properties are crucial. The decision between aluminum and steel ultimately depends on the specific requirements of the project, including factors such as strength, weight, corrosion resistance, and cost. As technology continues to evolve, both materials will play significant roles in meeting the demands of modern engineering and construction.

Aluminum's primary advantage is its lightweight nature combined with a favorable strength-to-weight ratio, making it ideal for applications where weight reduction is critical.

Aluminum generally has a lower tensile strength than steel. For example, aluminum alloy 6005-T5 has a tensile strength of about 37,700 psi, while mild steel can have a tensile strength of around 55,000 psi.

Aluminum extrusions are commonly used in aerospace, automotive, construction, electronics, and marine applications due to their versatility and corrosion resistance.

Generally, steel is cheaper by weight than aluminum, although certain types of stainless steel can be comparable in price to aluminum alloys.

Aluminum is highly recyclable and requires less energy to recycle than steel, making it a more environmentally friendly option for many applications.

[1] https://anglelock.com/blog/t-slot-aluminum-strength-vs-welding

[2] https://www.clickmetal.co.uk/blog/post/aluminium-vs-steel-whats-the-difference

[3] https://qst-corp.com/2024/01/12/aluminum-extrusion-parts-and-hardness/

[4] https://www.aluminiumalca.com/blog/exploring-the-advantages-and-applications-of-aluminum-extrusion/1/

[5] https://simmal.com/10-surprising-uses-for-aluminium-extrusion-you-didnt-know/

[6] https://www.ulmaforge.com/en/new/steel-characteristics-properties-and-uses/

[7] https://cuttingedgesolutions.com.au/common-uses-of-steel-in-construction-and-manufacturing/

[8] https://ezimetal.com.au/blog/steel-vs-aluminium-sheets-pros-cons/

[9] https://www.wasatchsteel.com/steel-vs-aluminum-for-construction-basic-comparison/

[10] https://endura-steel.com/aluminum-vs-steel-strength-weight-and-applications-compared/

[11] https://www.madearia.com/blog/aluminum-vs-steel/

[12] https://kundel.com/some-interesting-facts-about-using-aluminum-extrusion/

[13] https://eagle-aluminum.com/steel-vs-aluminum/

[14] https://industrialmetalservice.com/metal-university/steel-vs-aluminum-understanding-the-difference-between-ferrous-and-nonferrous-metals/

[15] https://aec.org/faqs

[16] http://www.kastenmarine.com/alumVSsteel.htm

[17] https://www.yjing-extrusion.com/what-are-the-key-strength-characteristics-of-2020-aluminum-extrusions.html

[18] https://exlabesa.com/uk/2023/05/19/is-extruded-aluminum-stronger-than-steel/

[19] https://www.unifiedalloys.com/blog/stainless-steel-vs-aluminum

[20] https://hitopindustrial.com/aluminum-extrusion-process/

[21] https://jmaluminium.com/exploring-the-world-of-aluminium-extrusion-profiles-what-they-are-and-how-theyre-used/

[22] https://www.hydro.com/profiles/uses-of-aluminum-extrusions

[23] https://proax.ca/en/blog/post/aluminum-extrusion-manufacturing-applications

[24] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[25] https://www.zetwerk.com/aluminum-extrusions/

[26] https://tubecon.co.za/technicalinfo/tubeconwikisub/MechanicalPropertiesOfCommonSteel

[27] https://www.rtprototype.com/what-is-steel/

[28] https://www.gz-supplies.com/news/the-uses-of-structural-steel-in-construction-and-manufacturing/

[29] https://www.totalmateria.com/en-us/material-basics-properties/steel-properties/

[30] https://kingsunmachining.com/blog/properties-for-steel/

[31] https://www.linkedin.com/pulse/advantages-disadvantages-aluminum-stainless-steel-machining-huang-jackc

[32] https://www.icbfabrications.co.uk/blog/aluminium-vs-steel

[33] https://www.erectastep.com/blog/aluminum-steel-metal-better/

[34] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[35] https://www.linkedin.com/pulse/differences-between-aluminum-steel-jsibuilt

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden