English

Views: 222 Author: Astin Publish Time: 2025-04-01 Origin: Site

Content Menu

● Introduction to Aluminum Extrusion

>> Key Steps in Aluminum Extrusion

● Applications of Extrusion Profiles Aluminum

● Advantages of Extrusion Profiles Aluminum

● Challenges in Manufacturing Extrusion Profiles Aluminum

● Sustainability in Aluminum Extrusion

● Future Developments in Aluminum Extrusion

● Innovations in Extrusion Techniques

● FAQs

>> 1. What is the primary method used to shape aluminum into extrusion profiles?

>> 2. What are the common applications of extrusion profiles aluminum?

>> 3. How are extrusion profiles cooled after emerging from the die?

>> 4. What is the purpose of aging in the aluminum extrusion process?

>> 5. What surface treatments can be applied to extrusion profiles aluminum?

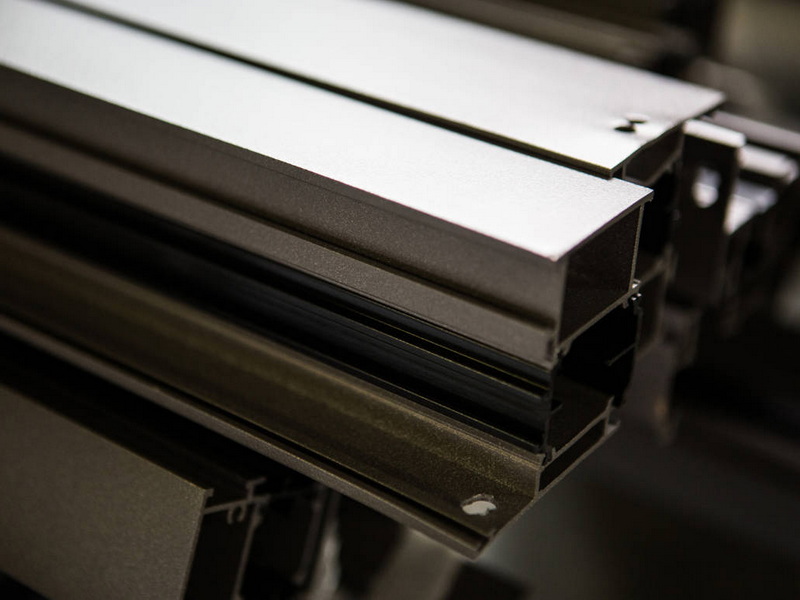

The process of creating extrusion profiles aluminum involves a series of complex steps that transform raw aluminum into versatile, lightweight, and strong profiles. These profiles are widely used in various industries, including construction, automotive, aerospace, and more, due to their excellent strength-to-weight ratio and corrosion resistance. In this article, we will delve into the detailed process of manufacturing extrusion profiles aluminum, exploring the techniques, tools, and applications involved.

Aluminum extrusion is a manufacturing process that shapes aluminum by forcing it through a die with a specific cross-sectional profile. This process can be likened to squeezing toothpaste from a tube, where the toothpaste takes the shape of the tube's opening. Similarly, aluminum extrusions take the shape of the die used in the process. The versatility of this method allows for the creation of almost any imaginable shape, making it a crucial technique in modern manufacturing.

1. Die Preparation: The die is crafted to match the desired cross-sectional profile of the final product. It is preheated to ensure even metal flow and maximize its lifespan.

2. Billet Preheating: An aluminum billet, a cylindrical block of aluminum alloy, is heated in a furnace to a temperature between 400°C and 500°C. This makes the aluminum malleable but not molten.

3. Extrusion: The preheated billet is placed into the extrusion press, where a hydraulic ram applies pressure to push the aluminum through the die. The pressure can range from 100 tons to 15,000 tons, depending on the complexity of the shape and the size of the extrusion.

4. Quenching: After emerging from the die, the extrusion is quenched using water or air to rapidly cool it. This step is crucial for setting the shape and improving the mechanical properties of the aluminum.

5. Stretching and Straightening: The cooled extrusion may undergo stretching to correct any distortions and ensure straightness.

6. Cutting: The extrusions are cut to the desired lengths using saws or shearing machines.

7. Aging: Some extrusions are heat-treated in aging ovens to enhance their strength and hardness, achieving tempers like T5 or T6.

8. Surface Treatment: Optional treatments such as anodizing, powder coating, or painting can be applied to enhance appearance and corrosion resistance.

9. Quality Inspection: Final profiles are inspected for dimensional accuracy and surface quality.

10. Packaging and Delivery: The finished extrusion profiles aluminum are packaged and shipped to customers for further fabrication or assembly.

Extrusion profiles aluminum are highly versatile and find applications in numerous industries:

- Construction: Used in building frames, windows, doors, and other structural components due to their strength and lightweight nature.

- Automotive: Employed in vehicle frames, engine components, and body parts for their high strength-to-weight ratio.

- Aerospace: Utilized in aircraft structures for their lightweight yet strong properties.

- Renewable Energy: Used in solar panel frames and wind turbine components.

The advantages of using extrusion profiles aluminum include:

- Lightweight: Aluminum is significantly lighter than steel, making it ideal for applications where weight reduction is crucial.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing excellent corrosion resistance.

- Strength-to-Weight Ratio: Offers a high strength-to-weight ratio, making it suitable for structural applications.

- Versatility: Can be extruded into complex shapes with precise dimensions.

Despite the advantages, there are challenges in manufacturing extrusion profiles aluminum:

- Die Design Complexity: Creating dies for complex shapes can be challenging and costly.

- Material Selection: Choosing the right aluminum alloy is critical for achieving desired properties.

- Quality Control: Ensuring consistent quality across large production runs requires rigorous quality control measures.

Aluminum extrusion contributes significantly to sustainable manufacturing due to aluminum's recyclability and low environmental impact:

- Recyclability: Aluminum can be recycled repeatedly without losing its properties, making it an environmentally friendly choice.

- Energy Efficiency: Aluminum extrusions help reduce energy consumption in buildings and vehicles by providing lightweight yet strong structures.

- Low Carbon Footprint: The aluminum industry is moving towards using low-carbon primary aluminum, further reducing its environmental footprint[3][6].

The future of extrusion profiles aluminum manufacturing involves advancements in technology and sustainability:

- Advanced Materials: Research into new aluminum alloys with improved properties.

- Sustainable Practices: Implementing environmentally friendly manufacturing processes.

- Digitalization: Integrating digital tools for more efficient design and production processes.

Recent innovations in extrusion techniques include the development of new processes like Lateral Angular Co-Extrusion (LACE), which allows for the creation of complex compound profiles with high bond strength[2]. Additionally, advances in forming curved profiles have expanded the possibilities for creating lightweight structures with high stiffness and strength, particularly in aerospace and automotive industries[4].

The aluminum extrusion market is experiencing significant growth, driven by increasing demand for lightweight materials in industries such as automotive and construction. The Asia Pacific region is particularly vibrant, with a projected CAGR of 8.7% from 2024 to 2030[8]. This growth is supported by advancements in extrusion technology and the shift towards sustainable practices.

In conclusion, the process of making extrusion profiles aluminum involves a combination of precise engineering, advanced machinery, and careful quality control. These profiles are indispensable in modern manufacturing due to their versatility, strength, and lightweight nature. As technology continues to evolve, we can expect even more innovative applications of extrusion profiles aluminum in various industries.

The primary method used to shape aluminum into extrusion profiles is by forcing the aluminum through a die using a hydraulic press. This process can create complex shapes with precise dimensions.

Extrusion profiles aluminum are commonly used in construction, automotive, aerospace, and renewable energy industries due to their strength, lightweight nature, and corrosion resistance.

Extrusion profiles are typically cooled using a water bath or air jets to rapidly quench them. This step is crucial for setting the shape and improving the mechanical properties of the aluminum.

Aging, or heat treatment, is used to enhance the strength and hardness of the aluminum extrusions, achieving tempers like T5 or T6. This process involves heating the extrusions in controlled environments.

Common surface treatments for extrusion profiles aluminum include anodizing, powder coating, and painting. These treatments enhance appearance and provide additional corrosion resistance.

[1] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[2] https://aec.org/extruder-design-innovation

[3] https://kimsen.vn/the-benefits-of-aluminum-extrusion-for-sustainable-manufacturing-ne142.html

[4] https://pmc.ncbi.nlm.nih.gov/articles/PMC8037283/

[5] https://www.designnews.com/industry/aluminum-extrusion-increases-options-to-optimize-the-supply-chain-part-1

[6] https://aec.org/sustainability

[7] https://pmc.ncbi.nlm.nih.gov/articles/PMC5455633/

[8] https://www.grandviewresearch.com/industry-analysis/asia-pacific-aluminum-extrusion-market-report

[9] https://aec.org/features-benefits

[10] https://pmc.ncbi.nlm.nih.gov/articles/PMC9739251/

[11] https://vocal.media/01/aluminum-extrusion-a-vital-manufacturing-process-driving-innovations

[12] https://pmc.ncbi.nlm.nih.gov/articles/PMC11123091/

[13] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/manufacturing-custom-aluminum-extrusion-profiles/

[14] https://www.grandviewresearch.com/industry-analysis/aluminum-extrusion-market

[15] https://pmc.ncbi.nlm.nih.gov/articles/PMC10944486/

[16] https://pmc.ncbi.nlm.nih.gov/articles/PMC9655778/

[17] https://www.grandviewresearch.com/industry-analysis/us-aluminum-extrusion-market-report

[18] https://aec.org/key-design-considerations

[19] https://pmc.ncbi.nlm.nih.gov/articles/PMC5455931/

[20] https://www.rapiddirect.com/blog/aluminum-extrusion-process/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden