What is Aluminum Fabrication?

Aluminum fabrication plays a crucial role in industrial manufacturing. It allows for a steady supply of products that drive exceptional results in different sectors. Through this process manufacturers can produce components and parts that meet project demands like precision, quality, strength and effective designs.

With aluminum fabrication you can achieve a wide range of products ideal for standard applications or critical uses. This manufacturing process also improves the safety and reliability of different projects.

Let’s get started on the basics of aluminum fabrication!

What Is Aluminum Fabrication?

The fabrication process is basically how different aluminum products are shaped. Because there are varying methods used by fabricators, the material exhibits different physical properties through all stages of the process. The desired characteristics determine the technique and the production cost of the fabrication process.

Why Is Aluminum Fabrication Important?

Aluminum fabrication is applied to designs of most everyday things. We would not be able to enjoy the benefits of some important items were it not for this process. Think of electronic devices, furniture, industrial equipment, home appliances, automotives, etc. Aluminum fabrication plays a key role in providing reliable products for the fast-paced modern society.

Common Aluminum Fabrication Processes

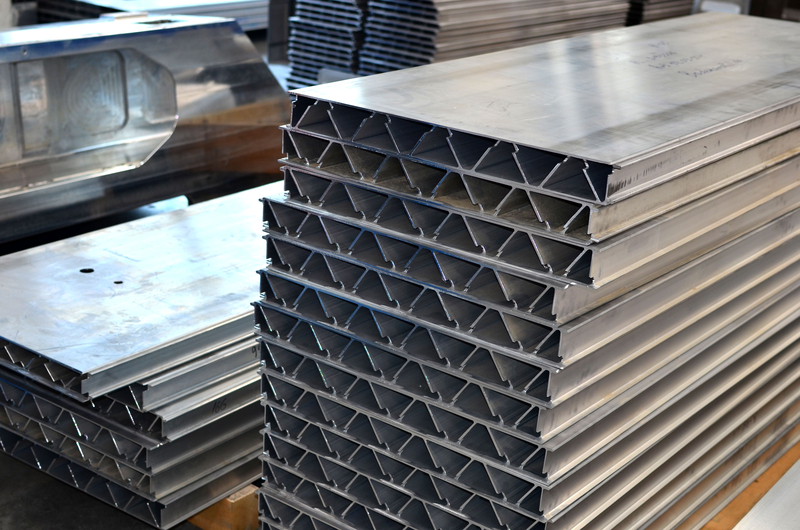

Extrusion

This is a process where an aluminum alloy is heated and passed via a die. A ram is used to exert pressure that enables the die to move the alloy until it reaches the runout table. The dies come in different dimensions to facilitate the varying product specifications.

The basics of the extrusion process are fundamentally easy to comprehend; a commonly used concept that can allow you a simple understanding is how you exert pressure on a toothpaste tube.

Think of the tube opening as the die opening. The toothpaste takes the shape of the tube opening while it flows out.

Casting

One of the single-stage processes that is highly essential during the production of intricate parts is aluminum casting. The liquid aluminum metal is carefully designed into finished products which can be used in high load applications. This is done by feeding softened aluminum in a cavity where the part is formed.

Because the manufacturing process has shortcomings, the manufacturers explore design considerations that enhance the reliability of aluminum casted products in demanding applications.

Also, although aluminum casting products are more prone to abrasion, cracking and shock loading however; there are ways to work around the design process.

Rolling

The rolling process is essential in metal work. It is a principle way of transforming aluminum casts into more efficient products. This process can alter the dimensions of cast slabs making them plate material of a reduced size.

In fact, rolling allows for extremely small thicknesses (below 0.006mm). You can use thick rolled aluminum parts for structural projects and thinner ones for everyday items like foils and cans.

Forging

This is the use of pressure to achieve varying aluminum shapes and sizes. The manufacturer uses a hammer or press to control the amount of pressure required to achieve the desired aluminum forms.

You can achieve durable, high strength and corrosion resistant aluminum forms suitable for use in the defense, aerospace or automobiles fields

.

Advantages of Aluminum in Fabrication

Durable

The durability of aluminum is proven through prolonged use in structural and architectural applications over the years. Aluminum stands out among other manufacturing materials like polymers and timber because of its non-corrosive property. It works great for both indoor and outdoor applications and doesn't contain iron which is pervious to rusting in harsh conditions. Another property that enhances the corrosion resistance of the metal is that it contains an aluminum oxide outer surface that acts as protection

Lightweight but Strong

Metal fabrication is a complex process that requires the right material and skill. The versatility and lightweight of aluminum mean there is more leeway during fabrication although the material needs careful handling through the different stages.

Cost-Effective

Aluminum fabrication is one of the greatest production methods. It enables manufacturers to produce quality products in a cheaper way compared to other metal fabrication processes.

First you don't require advanced machinery to form or cut the material unless you are working on large bulks or complex parts. Also, the lead time is significantly shorter compared to steel fabrication.

Easy to Cut

Aluminum density does not get in the way of its workability. Fabricators can apply different cutting techniques to achieve precise or custom forms like large beams and small plates as well.

Conclusion

We hope that you have gained a basic understanding of aluminum fabrication. Understanding fabrication techniques, common uses and aluminum properties is a great start if you are looking to start a business or make an impact in the marketplace.

At WEIYE we take into account project specific considerations to help you find the ideal alloy that you desire. Aluminum boasts many beneficial chemical and mechanical properties hence its proven popularity in the industrial sector.

Custom aluminum fabrication is used in the production of a substantial range of products around the world. Well regarded for its many favorable mechanical and chemical properties, aluminum fabricated products are essential to nearly every industrial sector.