Various Types of Aluminum Channels

Aluminum channels have revolutionized the construction industry. Thanks to their versatility, they are widely used in architectural, structural, and industrial applications. Other uses are car and machine repairs. Read on for the most popular channel types and their various applications.

What is an Extruded Aluminum Channel?

The term "aluminum extrusion" refers to a technique through which an aluminum alloy is pushed into a die with a specific cross-section profile. When aluminum is heated and pushed through a die under high pressure, the final product of the process is known as the channel.

The forming process of aluminum channels involves placing the aluminum into a press and heating it until it reaches a 900 degrees F temperature. The aluminum metal is then pushed out the die opening using an extrusion press. These channels will look great when installed, and maintaining them is no hassle.

Types of Aluminum Channels

U-Channels

U-channels are primarily popular and have numerous applications in building and engineering. They are three-sided, with the two parallel flat sides meeting at 90 degrees hence the U shape, as the name suggests. These channels are used to reinforce and support panels, beams, and other structures. Other uses include the making of tracks, railings, and rims.

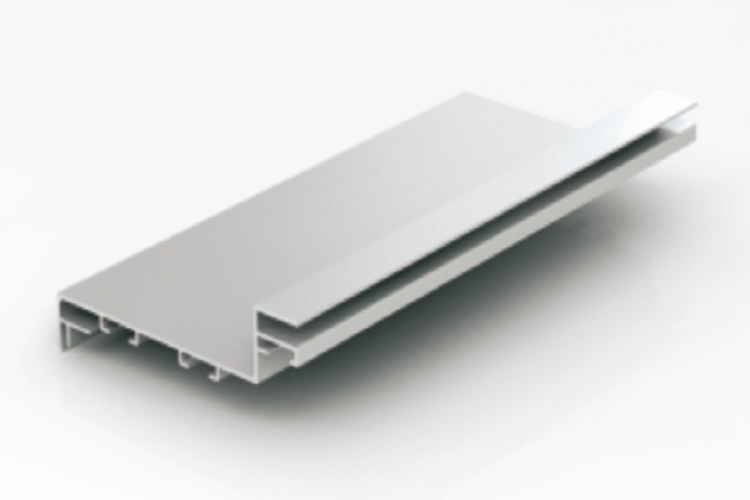

Aluminum Hat Channels

This is the most unique of all the types. The hat shape of the aluminum channel comes from a combination of two outward flanges (horizontal) and vertical dimensions. You can get aluminum channels to your specific requirements in length and width. The standard length is 005" - 150",while the maximum height for the hat channels is 5.25 inches.

Aluminum hat channels are essential for leveling ceilings and stone walls because they produce a flat, stable surface. Curtain walls are also among other uses of hat channels.

Aluminum C Channels

Think of this aluminum channel as a sister to the aluminum U and J channel type. This aluminum ranges in thickness from 0.003 inches - 0.500 inches. It plays an essential role throughout the manufacturing and industrial sectors and is readily available online or in appliance shops. Of Course, you will find it in the dimensions suitable for your applications.

T-slot Channel

This aluminum channel boasts a T shape which makes it unique. It features a top groove for fast and simple connection and detachment of different parts. For this reason, they're so helpful in manufacturing and other industries where versatility and customization are essential. Some of the uses of T-slot channels are conveyors and custom work desks, among others.

Benefits of Aluminum Channels

- Excellentthermal and electrical conductivity-Aluminum channels are used forhigh-capacity power lines. Thanks to this property, their conductivity istwice as high as copper's.

- CorrosionResistance- Aluminum channels have an oxide coat that shields them fromthe effects of corrosion when exposed to oxygen, which can be furtherstrengthened through anodizing.

- Sturdyand lightweight aluminum has an excellent strength-to-weight ratio, so itis your best bet as a load-bearing option.

- Non-Magnetic-Aluminum channels are non-magnetic, making them suitable for applicationsthat require this property.

- Recyclable.Aluminum channels can be recycled without sacrificing their quality.Furthermore, processing recycled aluminum uses just 5% of the energyneeded to produce virgin aluminum.

- Shieldingand Heat Conduction-Aluminum's higher heat transmission and shieldingfeatures over copper are particularly beneficial in aircraft applications,where lightweight and rigidity are crucial.