The Application of Aluminium Profiles in Building

Picture this, having a unique tool that can help you not only shape your views without restricting your creative acumen. Designers, engineers, and even modern architects are lucky to have a unique metallic element that can steer their design ideas in construction projects. This is exactly what you get with aluminum profiles.

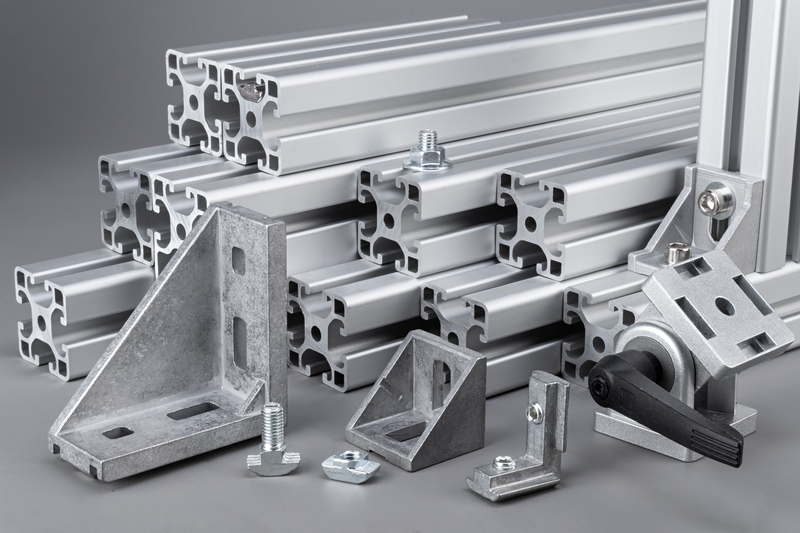

These simple, yet inventive metal fabrication products have eased the process of building and construction with applications around multiple tasks including modeling, structural, and different framing jobs.

Below are several common uses of aluminum profiles:

Superior Door and Windows Systems

Any quality door and window require superior material to enhance both their functional coordination and durability. Aluminum profiles are important elements in creating this systematic door and window designs.

By using aluminum profiles, manufacturers create unique thermal break profiles, unique window frames and designs, and durable door frames that ensure functions and performances of the doors are standardized and durable enough for proper use.

Durable Curtain Walls

Another remarkable application of aluminum profiles is the manufacture of robust curtain walls. The curtain walls are widely used in the construction industry and their primary structural material is usually aluminum, ferrum, or wood. Curtain walls are used in proper structuring of canopy, daylight roof, and wall plates.

Aluminum profiles are used in creating different shapes and types of curtain walls for various applications including panels, fabric veneer, vents and windows. Ideally, aluminum profiles create remarkable architectural decorations, and are used in various other functions like in indoor walls in communication rooms, stadiums, trains stations, and even in museums.

Top-grade Facade Cladding

All the uses of these profiles are inspired by their remarkable features. One such unit is an exterior façade that is weather resistant. The current construction designs are majorly focused on the overall aesthetic and this makes aluminum cladding an immensely used component.

They are applicable for building exteriors for aesthetic, functional, and economic purposes. Manufacturers use aluminum to create composite panels which are vastly used for their different color options in addition to low maintenance installation.

Quality Aluminum Handrail

Aluminum profiles are also important components in the creation of handrails. With aluminum profiles, you can have artistically functional and secure aluminum handrails. By using aluminum profiles, you have durable, lightweight, and affordable handrails that are corrosion-resistant. Aluminum profiles are popular components in the construction of handrails since they are durable and corrosion-resistant, and most importantly appealing to the eye.

Quality Aluminum Ceiling

A ceiling is a vital addition in a building since it enhances the space’s vision and appearance. Ceilings are also vital as reliable indoor decoration bases depending on the type of material used. Aluminum profiles are used to make robust ceiling plates usually processed through heat treatment.

This process ensures that the ceiling plates generate different colors and marks. With aluminum profile-based ceilings, you can be certain of inflammable, anti-corrosion, and waterproof ceilings for your building. What’s more, compared to plastic and PVC, aluminum profiles result in recyclable and durable ceilings that offer better performance.

Why Are Aluminum Profiles Used in Construction?

These profiles can be designed in numerous treatment techniques and finishes. This makes them superior in performance, highly thermal effective, and comes with minimal to no maintenance costs allowing use in nearly all conditions. These profiles are applied in specific environments with bad climate changes, high humidity, and coastal regions.

Furthermore, in comparison to steel, the use of these profiles is encouraged because of their formability, and plasticity. These units can be processed into different shapes and specifications in massive quantities in hot and cold conditions through various pressure processing techniques like forging, extrusion, and even rolling among others.

Die forgings, plates, pipes, and rods among other provisions can lead to creation of more reasonable components.

Additional benefits of using these units include:

● Cost efficiency

● Small/Minimal construction effort

● Numerous application options