Aluminum Extrusion Solutions for the Automotive Industry

Aluminum has rapidly become a part of numerous industries, from the usual traffic and lighting equipment to electronic gadgets. This has been made possible by the handy aluminum extrusion process; a procedure that’s taking numerous industries by storm.

Moreover, extruded aluminum is usually utilized in multiple other daily projects like manufacturing car parts, kitchen utensils, and so on. Here is more on how aluminum extrusion is expedient for the automotive industry:

Benefits of Aluminum Extrusions for the Automotive Industry

Lightweight

Aluminum is generally lightweight, and so is extruded aluminum. For this reason, it is a preferred material in the automotive industry.

Automobile manufacturers are always looking for better ways to decrease their vehicles’ weight, reduce emissions and promote energy efficiency; and aluminum extrusion fixes all of these problems.

Compared to other metals it provides a substantial weight decrease, making it perfect for applications like suspension parts, chassis and body parts.

Multifaceted Geometrics

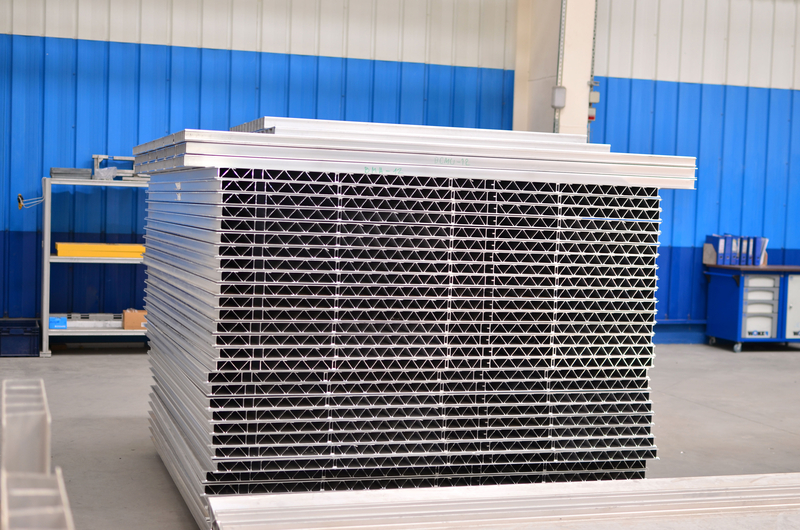

Aluminum extrusion is one of the few processes that can produce aluminum with different-featured designs and shapes with unmatched ease. Similarly, with this great technology, it is easy to generate various complex shapes & designs that would otherwise be hard, especially with traditional machines.

For this reason, automobile manufacturers yield high-strength and light components that deliver incredible functionality & performance.

Sustainability

Vehicles are designed to be durable and sustainable. Fortunately, aluminum extrusion ensures that the final product is both sustainable and resilient.

Aluminum is recyclable, therefore, when it’s being extruded, there is minimal energy used. For this reason, aluminum extrusion is a preferred production process, compared to other traditional procedures.

Moreover, aluminum extrusion ensures the final product has low carbon footprint, making it a better option that leaves the planet safer.

Extrusion & Fabrication

Steel has been in the industry for a long time but aluminum is now becoming more popular thus gradually replacing it on car parts like outer body, battery box, rockers and cross car beams.

Additionally, aluminum extrusion yields final products that are both lightweight and robust, thus the automotive industry uses such parts because they are more effortless to secure & transport. The beams and other car parts that run consistently, and they are also built using extruded aluminum for improved longevity and durability.

Then, these parts including extruded aluminum are handy in reducing the overall weight of the car, which in turn boosts energy efficiency. On top of that, these parts are affordable!

After the production of the aluminum profile or die, bulk production will be a breeze, since you already have the desired design settings. The aluminum may be manufactured swiftly because there are no extra processes needed like fabrication.

Automotive Industry Prospects for Aluminum Extrusion

The Body

Most automobiles have their exterior bodies made of extruded aluminum. This is thanks to aluminum’s lightweight natures and high-strength features. The employment of extruded aluminum for such works will reduce the overall weight of the car, which ensures great energy efficiency and less emission.

Besides, extruded aluminum can be manufactured intentionally, to minimize the effects of impact, which ensures the safety of the passengers.

Chassis Parts

Aluminum extrusion provides improved rigidity and resilience, which is why it’s better than other production processes. Thanks to this, you can attain better handling and steadiness. Additionally, the use of aluminum extrusion will reduce the overall weight of the automobile, and improve energy efficiency.

Outer Trim

The other way aluminum extrusion helps in the automotive industry is that it is utilized in manufacturing automobile’s outer trim components like the window frames and roof rails.

Plus, they deliver superior corrosion resistance and durability, compared to other materials. This makes them the most suitable materials to employ in harsh environs.

What’s more, vehicle manufacturers like employing aluminum extrusion as it delivers a good-looking and streamline appearance.

In Conclusion

Clearly, aluminum extrusion is an incredibly useful process and it carries numerous solutions for the automotive industry. It presents so many benefits, including the lightweight nature, robustness and sleek appearance.

Plus, fuel efficiency is something you can benefit from if your vehicle is built using extruded aluminum. Also, if you are looking to trigger the eco-warrior in you, then aluminum extrusion will help you achieve that too. The automotive industry is progressively advancing so there are high chances we will continue seeing the utilization in vehicles and manufacturers look for more ways to boost sustainability, safety and performance.