6 Factors Related To Industrial Aluminum Profiles

Industrial aluminum profiles are very versatile fundamental components utilized in countless ways, from building to transport and consumer goods machines. These extrusion shapes offer a unique combination of strength, lightweightness and formability that makes them popular with engineers and designers for many applications.

Nevertheless, picking the right profile requires taking into account a number of factors to ensure it has optimum performance and functionality. In this regard we discuss six major factors that influence the choice of industrial aluminum profiles:

Alloy Selection: Strength in Numbers

The specific characteristics of an aluminum profile depend heavily on the alloy chosen. Different alloys offer different strengths, corrosion resistances and workability. Here’s a breakdown of some common alloy groups:

1. 1XXX Series (Pure Aluminum): Known for its excellent ductility and formability that is ideal for bending or shaping applications although it offers lower strength compared to other alloys.

2. 6XXX Series (Heat Treatable): High strength is achieved by these alloys through heat treatment thus they find suitability in structural applications as well as harsh environments.

3. 5XXX Series (Magnesium-Rich): It provides good balance between strength and corrosion resistance; therefore, commonly used in marine environments, building components, transportation etc.

4. Zinc Rich 7XXX Series: They are the strongest common aluminum alloys and are suitable for applications such as aerospace and heavy machinery requiring high strength.

Profile Shape

The shape of the profile greatly influences its functionality and performance. These include:

1. Solid profiles - These have maximum strength making them excellent for application like beams and columns

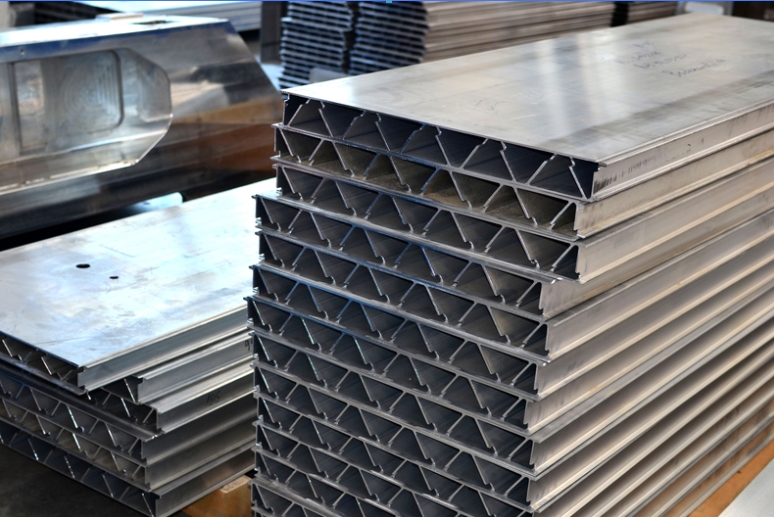

2. Hollow profiles - Hollow profiles are lighter, cheaper and come in different shapes like tubes, angles or channels. They have good strength to weight ratios for framing, enclosures etc.

3. Custom designed or complex profiles - Profiles that can be made to desired specifications/requirement i.e. think of complex shapes used in machine parts, heat sinks etc.

Temper

An ideal balance has to be struck on this front. Temper is the controlled thermal and mechanical treatment that changes the properties of the profile. Here’s it broken down (in simpler terms):

1. T4-T4 means work-hardened for increased strength but reduced formability (bending or shaping).

2. T6- T6 is typified by solution treatment following work hardening, providing the highest combination of formability with better than average tensile properties.

3. H temper – This strain hardened state creates good formability at some expense of strength.

Wall Thickness

Profile’s strength and weight both depend on its wall thickness. Assuming you have a stronger profile at hand, you are going to notice it’s got slightly thicker walls. What blind you from their expensive prices is they have a good load bearing capacity.

Now if we get to the lighter and more cost-effective profiles, you realize that they tend to possess less load bearing capacity. Usually balancing the priority of these aspects with your particular use requires picking the right thickness.

Surface Treatments

Different finishes can be applied to aluminum profiles in order to enhance their aesthetics and performance as well. While we mention them below, the thing is that the surface finishing needs to be suited to application settings.

1. Anodizing: The finish produces a protective oxide layer that increases corrosion resistance and can also be dyed for aesthetic reasons;

2. Powder coating: Colorful films that are resistant to weathering;

3. Chemical film: Provides slight protection from corrosion as well as assisting paint adhesion.

Fabrication Considerations

The final factor is how the profile will be manufactured into its intended product. Some of the common fabrication techniques used include:

1. Cutting: Profiles can be cut to length using saws or CNC machines with high precision.

2. Machining: Drilling holes, cutting threads, etc., can then be done on such a profile when assembling it.

3. Bending: Professional machines could allow some profiles to have angles bent in them.

4. Welding: This is how two different profiles get to be linked mostly in play is the compatible filler metals and a variety of welding techniques.

Consider these six factors and while thinking in mind for a particular project to be selected in the industrial aluminum profile, allow profile design, temper, wall thickness, surface treatment and fabrication procedures.

Aluminum so far remains a recyclable green warrior, the good fighter. It should not be so much about performance now but about catching that ecological wave with a lot of grooves. Recycling centered aluminum profiles are invited to the sustainability party where they will support green courses and the pursuit to ensure industrial endeavors leave a green legacy.