English

Views: 222 Author: Astin Publish Time: 2025-04-01 Origin: Site

Content Menu

● Introduction to Modular Aluminum Profiles

>> Key Benefits of Modular Aluminum Profiles

● Applications of Modular Aluminum Profiles

● Sustainability and Environmental Impact

● Modular Profile Systems in Mechanical Engineering

● Customization and Adaptability

>> 1. What are the primary benefits of using modular aluminum profiles in large-scale projects?

>> 2. How do modular aluminum profiles contribute to sustainability?

>> 3. Can modular aluminum profiles be customized for specific applications?

>> 4. What types of projects are modular aluminum profiles most suitable for?

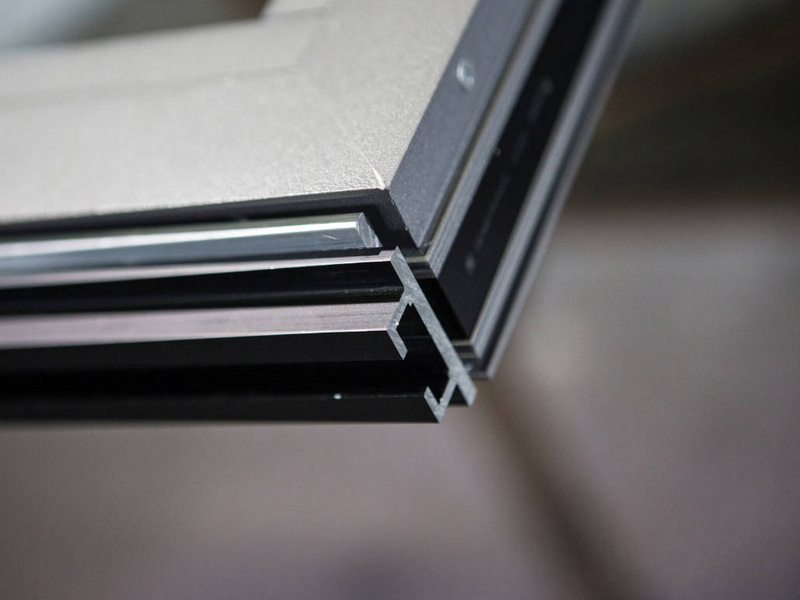

In recent years, modular aluminum profiles have gained significant attention in the construction and design industries due to their versatility, sustainability, and cost-effectiveness. These profiles are made from aluminum alloys that are shaped through an extrusion process, resulting in lightweight yet strong structures that can be easily assembled and reconfigured. This article will delve into the benefits of using modular aluminum profiles in large-scale projects, exploring their cost-effectiveness, sustainability, and adaptability.

Modular aluminum profiles are designed to provide both structural and architectural elements that can be quickly assembled and disassembled. They are ideal for projects that require flexibility and scalability, as they allow for easy modifications and expansions without the need for extensive dismantling or reconstruction. The modular nature of these profiles makes them highly versatile, suitable for a wide range of applications from machine frames and workstations to large-scale architectural projects like airports and skyscrapers.

1. Cost-Effectiveness: Modular aluminum profiles offer a cost-effective solution by allowing the reuse of components and minimizing the need for continuous material purchases. Their durability and resistance to corrosion also reduce maintenance and replacement costs over time.

2. Sustainability: Aluminum is 100% recyclable, requiring significantly less energy for recycling than its initial production. This eco-friendly property makes modular aluminum profiles an environmentally sustainable choice for large-scale projects.

3. Flexibility and Scalability: These profiles facilitate easy component replacements and design adjustments, making them ideal for projects with evolving requirements. This flexibility ensures uninterrupted operations and reduces costly downtime.

4. Strength and Durability: Despite being lightweight, modular aluminum profiles provide excellent strength-to-weight ratios, making them suitable for demanding environments and large-scale applications.

5. Aesthetic Appeal: Modular aluminum framing systems allow for unique, customized architectural designs that can enhance the aesthetic appeal of structures.

Modular aluminum profiles are used in a variety of industries and applications:

- Construction and Architecture: They are used in building frames, facades, and interior structures due to their strength, durability, and aesthetic appeal. Projects like the Burj Khalifa and Beijing Daxing International Airport showcase their versatility in large-scale architectural designs.

- Industrial and Manufacturing: Modular aluminum profiles are used in machine building, automation, and material handling systems due to their flexibility and ease of assembly. For example, item's MB Building Kit System provides a universal solution for machine and equipment construction, offering profiles like Line 5, Line 6, Line 8, Line 10, and Line 12, each designed for specific load-bearing capacities and applications[1].

- Furniture and Interior Design: They are used in creating modular furniture and shelving systems, offering a sleek and modern appearance. Modular aluminum profiles allow for customized solutions that can be easily adapted to changing living spaces[5].

Several case studies highlight the effectiveness of modular aluminum profiles in large-scale projects:

- Beijing Daxing International Airport: The airport's vast terminal structure is supported by a network of aluminum profiles, demonstrating their ability to create large open spaces efficiently. This design enhances passenger flow and improves the overall travel experience[2].

- The Burj Khalifa: The skyscraper's exterior is composed of thousands of aluminum and glass panels, showcasing the profiles' ability to withstand extreme wind loads and temperature variations. The clean and elegant facade not only improves the aesthetics of the building but also contributes to its energy efficiency[2].

- The Eden Project: This futuristic greenhouse in Cornwall uses aluminum profiles to create an optimal growing environment. Lightweight profiles help create large spaces with minimal obstructions, maximizing sunlight penetration and promoting plant growth[2].

The cost-effectiveness of modular aluminum profiles in large-scale projects can be analyzed from several perspectives:

- Initial Investment: While the initial cost of purchasing modular aluminum profiles might be higher than traditional materials, their long-term benefits significantly offset these costs. The ability to reuse and reconfigure components reduces the need for new materials, saving resources and money.

- Maintenance and Replacement: The durability and corrosion resistance of aluminum profiles minimize maintenance and replacement costs over time. This reduces the overall lifecycle cost of the structure.

- Flexibility and Adaptability: The modular design allows for easy modifications and expansions, reducing the costs associated with redesigning or rebuilding entire structures when project requirements change.

Modular aluminum profiles contribute to sustainable practices in several ways:

- Recyclability: Aluminum is fully recyclable, requiring less energy for recycling than its initial production. This reduces the environmental impact associated with raw material extraction and processing.

- Lightweight Nature: The lightweight nature of aluminum profiles reduces transportation emissions, further minimizing their carbon footprint.

- Longevity: The durability of these profiles ensures that structures remain functional for longer periods, reducing the need for frequent replacements and the associated environmental impacts.

In mechanical engineering, modular aluminum profiles offer significant advantages over traditional materials like steel. They are lighter, yet provide comparable strength, and require fewer processing steps—sawing, screwing, and assembling—without the need for specialized equipment or training[6]. This simplicity in assembly and modification allows companies to maintain control over project timelines and quality, reducing the likelihood of errors and delays.

One of the standout features of modular aluminum profiles is their extensive customization options. They can be tailored to fit specific project requirements through cutting, drilling, and joining. This flexibility is especially valuable in industries where custom-built structures are often required, such as manufacturing and automation[8]. The availability of various profile sizes, shapes, and finishes (e.g., anodized and powder-coated) makes them suitable for both functional and aesthetic purposes.

Modular aluminum profiles are indeed cost-effective for large-scale projects due to their versatility, sustainability, and adaptability. They offer a flexible and scalable solution that can be easily modified or expanded as project requirements evolve. Their eco-friendly properties and durability make them an attractive choice for industries seeking to minimize environmental impact while optimizing resources.

- Modular aluminum profiles offer cost-effectiveness, sustainability, flexibility, and durability, making them ideal for projects that require scalability and adaptability.

- They are made from 100% recyclable aluminum, requiring less energy for recycling than initial production. Their lightweight nature also reduces transportation emissions.

- Yes, modular aluminum profiles can be customized with various components and accessories to meet specific project needs. They can be tailored for different industries and applications.

- Modular aluminum profiles are suitable for a wide range of projects, including construction, industrial manufacturing, furniture design, and large-scale architectural projects.

- Modular aluminum profiles may have a higher initial cost but offer long-term savings through reusability, reduced maintenance, and the ability to adapt to changing project requirements.

[1] https://de.item24.com/en/theme-world/building-kit-system/item-profiles/

[2] https://www.mebel-alu.com/knowledges_post/case-studies-successful-projects-using-aluminum-frame-profiles/

[3] https://www.assemblymag.com/articles/83405-the-beauty-of-modular-profile-systems

[4] https://www.flexlink.com/en/portfolio/components-and-parts/aluminum-profiles

[5] https://www.aluminiumprofiles.in/Modular-Aluminium-Profiles

[6] https://blog.item24.com/en/item-world/aluminium-profiles-in-specialist-mechanical-engineering-ideas-and-advantages/

[7] https://btimetals.com/modular/

[8] https://nalbantal.com/en/features-of-industrial-aluminium-profiles/

[9] https://sotech-optima.co.uk/case-studies/

[10] https://www.boschrexroth.com/en/au/products/product-groups/assembly-technology/topics/aluminum-profiles-solutions-components/

[11] https://sinoextrud.com/aluminium-profiles-green-building/

[12] https://jmaluminium.com/uses-and-features-of-modular-aluminium-extrusions/

[13] https://www.minitecframing.com

[14] https://www.goldapple-alu.com/case-studies-successful-projects-using-industrial-aluminum-profiles-3.html

[15] https://www.alineautomation.com/7-uses-for-aluminum-profiles-in-event-production/

[16] https://www.disumtec.com/en/blog/23_.html

[17] https://www.minitec.de/en/produkte/profile-system/aluminium-profiles

[18] https://www.goldapple-alu.com/gd/benefits-of-modular-design-with-industrial-aluminum-profiles.html

[19] https://us.item24.com/en/areas-of-use/building-kit-system/

[20] https://www.linkedin.com/pulse/cost-benefit-analysis-modular-wiring-large-scale-projects-crsoe

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden