English

Views: 222 Author: Astin Publish Time: 2025-04-10 Origin: Site

Content Menu

● Introduction to Aluminum Corner Extrusions

>> Types of Aluminum Corner Extrusions

● Design Considerations for Framing

● Comparison with Other Materials

● Environmental Impact and Sustainability

● Innovations in Aluminum Extrusion Technology

● Case Studies of Successful Applications

● Future Trends in Aluminum Corner Extrusions for Framing

● Market Analysis and Growth Prospects

>> 1. What are the primary advantages of using aluminum corner extrusions in framing?

>> 2. How do aluminum corner extrusions compare to steel in framing applications?

>> 3. Can aluminum corner extrusions be customized for specific projects?

>> 4. What are the common applications of aluminum corner extrusions?

>> 5. How do I choose the right aluminum corner extrusion for my project?

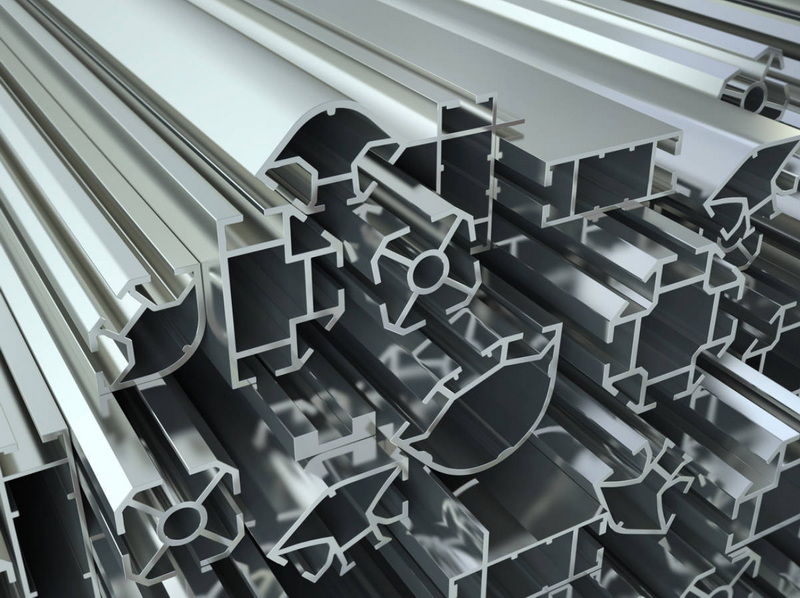

Aluminum corner extrusions have become a staple in various industries due to their versatility, durability, and cost-effectiveness. These extrusions are manufactured through a process that involves forcing heated aluminum through a die to create specific shapes, such as L-shaped, T-shaped, or angle-shaped profiles. The question remains whether these extrusions are suitable for framing applications. In this article, we will delve into the properties, applications, and advantages of aluminum corner extrusions to determine their suitability for framing.

Aluminum corner extrusions are designed to provide clean, seamless connections and enhance the overall strength and design of projects. They are commonly used in construction, architecture, manufacturing, and other sectors where precise angles and edges are crucial. The extrusion process ensures consistent dimensions, sharp corners, and smooth edges, making these components ideal for structural support, framing, and decorative elements.

1. Equal Angle Extrusions: These have two sides of equal length, meeting at a 90-degree angle. They are often used in structural frameworks, window and door frames, and shelving units.

2. Unequal Angle Extrusions: These have two sides of different lengths, also meeting at a 90-degree angle. They are commonly used in furniture construction, shelving, and framing.

3. L-Shaped (Right-Angle) Extrusions: Basic 90-degree angle extrusions used for corner reinforcement in door/window frames, furniture/cabinetry construction, and decorative trim.

4. Corner Guard Extrusions: Designed to protect corners from impact and wear, these are used in wall corner protection, high-traffic areas, and industrial/commercial buildings.

Aluminum corner extrusions offer several key properties that make them suitable for framing:

- Lightweight and Corrosion-Resistant: Aluminum is naturally lightweight and resistant to corrosion, making it ideal for applications where weight reduction and durability are important.

- Strength and Durability: The inherent strength of aluminum alloys, combined with the extrusion design, ensures that edges remain stable and resist deformation under pressure.

- Cost-Effectiveness: Aluminum extrusions are cost-effective due to their mass production capabilities and long lifespan, which reduces maintenance costs over time.

- Customizability: Aluminum can be finished in various ways, such as anodizing, powder coating, or painting, allowing it to blend seamlessly into different design styles.

Aluminum corner extrusions are widely used in framing systems across various industries:

- Construction and Architecture: They are used in structural framing, window and door frames, and curtain walls due to their lightweight nature and structural support.

- Furniture and Cabinetry: Aluminum corners provide strong joints in tables, chairs, and cabinets, enhancing stability and durability.

- Automotive and Aerospace: Aluminum extrusions play a critical role in constructing lightweight, fuel-efficient vehicles by reducing overall weight and improving performance.

When using aluminum corner extrusions for framing, several design considerations are crucial:

- Geometry and Material: The choice of alloy and temper affects the strength and durability of the extrusion. Common alloys include 6063 and 6061.

- Wall Thickness: Uniform wall thickness is ideal for production, but variations can be made based on strength requirements.

- Corner Radii: Corners should be rounded to avoid sharp edges, which can be aesthetically unappealing and prone to bending.

Aluminum framing is often compared to steel framing due to its advantages in certain applications:

- Weight and Corrosion Resistance: Aluminum is lighter and more resistant to corrosion than steel, making it suitable for outdoor and marine environments.

- Cost and Maintenance: While steel is stronger, aluminum's lower maintenance needs and recyclability make it a cost-effective choice over time.

- Modularity and Flexibility: Aluminum T-slot profiles allow for easy assembly and disassembly without welding, offering greater flexibility in design changes.

Aluminum corner extrusions have a significant environmental impact due to their material and production process. However, they also offer several sustainable benefits:

- Recyclability: Aluminum is highly recyclable, with a recycling rate of over 75% globally. This reduces waste and conserves natural resources.

- Energy Efficiency: The production of aluminum from recycled materials requires only about 5% of the energy needed to produce primary aluminum, making it an energy-efficient option.

- Durability: The long lifespan of aluminum extrusions reduces the need for frequent replacements, minimizing waste and the environmental impact of new production.

Recent innovations in aluminum extrusion technology have improved efficiency and expanded the capabilities of these components:

- Advanced Dies: New die designs allow for more complex shapes and tighter tolerances, enhancing the precision and versatility of extrusions.

- 3D Printing Integration: Combining aluminum extrusions with 3D printing enables the creation of complex structures that were previously impossible to produce.

- Sustainable Production Methods: Efforts to reduce energy consumption and emissions during the extrusion process are ongoing, making aluminum production more environmentally friendly.

Several notable projects demonstrate the effectiveness of aluminum corner extrusions:

- The Burj Khalifa: This skyscraper in Dubai uses extensive aluminum framing for its exterior cladding, showcasing the material's ability to support large-scale architectural designs.

- Tesla Electric Vehicles: Tesla incorporates aluminum extrusions in its vehicle frames to achieve lightweight yet robust structures, enhancing fuel efficiency and performance.

- Furniture Design: Companies like IKEA use aluminum corner extrusions in their furniture designs to provide durable and versatile products that are easy to assemble and disassemble.

Despite their advantages, aluminum corner extrusions also present some challenges:

- Strength Limitations: While strong, aluminum is generally weaker than steel, which can limit its use in high-load applications.

- Cost of Customization: While standard extrusions are cost-effective, custom designs can be more expensive due to tooling costs.

- Thermal Expansion: Aluminum expands more than steel with temperature changes, which must be considered in design to prevent structural issues.

Looking ahead, several trends are expected to shape the future of aluminum corner extrusions:

- Increased Use of Sustainable Materials: There will be a greater emphasis on using recycled aluminum and reducing waste in production processes.

- Advancements in Manufacturing Technology: Improvements in extrusion technology will enable more complex shapes and higher precision, expanding the range of applications.

- Integration with Emerging Technologies: Aluminum extrusions will be integrated with technologies like 3D printing and smart materials to create innovative products.

The market for aluminum corner extrusions is expected to grow due to increasing demand from the construction and automotive sectors. Factors driving this growth include:

- Global Infrastructure Development: As countries invest in infrastructure projects, the demand for lightweight, durable framing materials increases.

- Sustainability Initiatives: The push for sustainable building practices and energy-efficient vehicles will continue to drive the adoption of aluminum extrusions.

- Technological Advancements: Advances in extrusion technology will make aluminum more competitive against other materials, further expanding its market share.

Aluminum corner extrusions are indeed suitable for framing applications due to their strength, durability, and cost-effectiveness. Their versatility in design and functionality makes them a preferred choice in various industries, from construction to aerospace. By understanding the properties, applications, and future trends of aluminum corner extrusions, designers and builders can leverage these components to enhance both the form and function of their projects.

- Aluminum corner extrusions offer lightweight strength, corrosion resistance, and cost-effectiveness. They are easy to install and provide precise angles and edges, making them ideal for structural support and decorative elements.

- Aluminum is lighter and more corrosion-resistant than steel, making it suitable for applications where weight reduction and durability are crucial. However, steel is stronger and may be preferred in high-load applications.

- Yes, aluminum extrusions can be customized in terms of shape, size, and finish to meet specific project requirements. This includes various surface treatments such as anodizing or powder coating.

- Aluminum corner extrusions are used in construction (framing, window/door frames), furniture (cabinetry, shelving), automotive (lightweight vehicle components), and electronics (device enclosures).

- Consider factors such as geometry, material (alloy and temper), and finish. Ensure that the extrusion's strength and durability meet your project's requirements, and select a supplier that offers customization options if needed.

[1] https://www.chaluminium.com/aluminum-corner-extrusions-the-key-to-perfect-angles-and-edges

[2] https://www.flexmation.com/blog/the-advantages-of-aluminum-framing-over-steel-framing/

[3] https://orangealuminum.com/categories/shop-by-shape/corners.html

[4] https://tri-stateal.com/resources/extrusion-guide/

[5] https://www.yjing-extrusion.com/what-are-the-most-common-applications-for-aluminum-extrusion-corners.html

[6] https://www.alineautomation.com/beginners-guide-to-building-with-t-slot-aluminum-framing/

[7] https://www.wellste.com/aluminum-corner-extrusion/

[8] https://anglelock.com/blog/aluminum-extrusion-design-guide

[9] https://www.shapesbyhydro.com/en/design-thinking/extrusion-quick-guide-for-designing-with-aluminium/

[10] https://technical.europe.misumi-ec.com/en/support/solutions/articles/76000046645-aluminum-extrusions-general-questions

[11] http://scaluminum.com/2014/02/aluminum-extrusion-design-key-specs-that-must-be-considered/

[12] https://indianextrusions.com/category/aluminium-extrusions/Aluminium-Corner-Extrusion/

[13] https://www.minitecframing.com/Products/Floor_Mounting/Floor_Mounting_Catalog_Pages/21.1784_Corner_180.html

[14] https://vention.io/blogs/top-3-design-tips-for-effective-t-slot-aluminum-extrusion-structures-42

[15] https://8020.net

[16] https://it.misumi-ec.com/files/images/products/docs/framingsupport.pdf

[17] https://anglelock.com/blog/t-slot-hardware-aluminum-extrusion

[18] https://www.profall.com/en/aluminum-corner-extrusions

[19] https://www.profall.com/en/blog/l-shaped-aluminum-profile-a-versatile-extrusion-for-all-sectors

[20] https://www.gabrian.com/what-is-t-slot-aluminum/

[21] https://www.alibaba.com/showroom/aluminum-framing-corners.html

[22] https://alvaluminumprofiles.en.made-in-china.com/product/qQnUyeKoADcv/China-Radius-Corner-Aluminum-Extrusion-Profile-Aluminum-Framing-System.html

[23] https://www.profall.com/en/blog/aluminum-structural-profiles-use-and-fields-of-application

[24] https://jlcmc.com/blog/aluminum-extrusion-profiles-design-benefits

[25] https://www.gapengineering.com.au/blog/what-are-the-benefits-of-modular-aluminium-framing-systems/

[26] https://proleantech.com/aluminum-extrusion-explained/

[27] https://www.guangyaaluminium.com/blog/what-are-the-advantages-and-disadvantages-of-extruded-aluminum-profiles_b8

[28] https://eagle-aluminum.com/benefits-of-aluminum-extrusions/

[29] https://www.smartfix.com.au/blogs/aluminium-extrusions-sydney/

[30] https://engineeringproductdesign.com/knowledge-base/metal-extrusion/

[31] https://anglelock.com/blog/building-with-aluminum-extrusion-framing-systems-modular-adjustable

[32] https://www.reddit.com/r/simracing/comments/92qbpw/is_aluminium_2020_or_2040_extrusion_good_enough/

[33] https://resource.download.wjec.co.uk/vtc/2016-17/16-17_1-4/website/category/5/4thermoforming_and_thermosetting_polymers/extrusion_moulding/index.html

[34] https://www.alufabinc.com/why-use-aluminum/

[35] https://www.youtube.com/watch?v=_9sNCqBUSas

[36] https://www.capral.com.au/applications/project-case-studies/

[37] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-applications-of-aluminum-extrusion-profiles-in-various-industries/

[38] https://ai.motion.com/building-aluminum-t-slot-frames-without-machining/

[39] https://vention.io/resources/guides/t-slot-aluminum-extrusion-structure-design-guide-77

[40] https://www.framingtech.com/products

[41] https://www.profall.com/en/blog/structural-aluminum-extrusion-profiles-use-and-fields-of-application

[42] https://www.youtube.com/watch?v=CwGimohCH8A

[43] https://www.industrialprofile.com

[44] https://www.uniqueextrusions.com/aluminum-extrusion-faq/

[45] https://www.fonnovaluminium.com/faqs

[46] http://sicyonaluminium.com/faq.php

[47] https://eagle-aluminum.com/faqs/

[48] https://www.alumil.com/extrusion/info/resources/faq

[49] https://parco-inc.com/t-slot-aluminum-frequently-asked-questions/

[50] https://extrude-a-trim.com/faqs/

[51] https://www.profall.com/en/what-is-an-aluminum-profile

[52] https://aluminium.org.au/wp-content/uploads/2023/01/Aluminium-Extrusion-Manual-Feb23.pdf

[53] https://tri-stateal.com/blog/aluminum-extrusions-guide/

[54] https://anglelock.com/blog/custom-aluminum-extrusion-cost

[55] https://extrude-a-trim.com/different-names-for-aluminum-extrusions/

[56] https://www.reddit.com/r/Reprap/comments/nxjugf/how_do_you_assemble_aluminum_extrusions_as_a/

[57] https://www.alexandriaindustries.com/wp-content/uploads/2016/08/aec_manual_design.pdf

[58] https://www.weiye-aluminium.com/what-are-the-benefits-of-custom-aluminum-corner-profiles.html

[59] https://anglelock.com/blog/aluminum-structural-framing-systems-t-slot

[60] https://waykenrm.com/blogs/aluminum-extrusion/

[61] https://haluminium.com/Product/aluminum-extrusion-molding/

[62] https://shengenfab.com/ja/aluminum-extrusion/

[63] https://www.mknorthamerica.com/Products/extruded-aluminum-framing/

[64] https://palettiusa.com/aluminum-framing

[65] https://www.mebel-alu.com/knowledges_post/case-studies-successful-projects-using-aluminum-frame-profiles/

[66] https://eagle-aluminum.com/products/aluminum-corners-in-out/

[67] https://www.industrialprofile.com/aluminum-extrusion-joints-design-and-assembly-considerations/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden