English

Views: 0 Author: Site Editor Publish Time: 2022-12-27 Origin: Site

Ladies and gentlemen, come closer, for today we take a thrilling trip into the world of aluminum extrusion! Now, before we plunge right in and get our hands dirty with all that nitty-gritty action this process entails, let's just take a moment to think about how omnipresent aluminum is in virtually every aspect of our lives. Imagine life without it – no airplanes, buildings scraping the skies, or even sleek smartphones! Unthinkable, isn't it? But not so long ago, this precious metal was very far from being anything similar to what it has become today.

To maximize the visibility of aluminum, manufacturers employ an exclusive process coined as "extrusion." Now let's break down this intricate ballet of metal transfiguration one step at a time.

Preparing for action, we position our round rods horizontally on top of each other—appropriately spaced apart. No stacking because that could pose a risk to the machine and add tension which is totally unwarranted for any manufacturer to cope with.

Now things start to get a little hot in here! The heat is turned up but not too much. Control of the temperature right now is very crucial and we need it at around 400 to 500 degrees Celsius. You're probably asking why I have such an exact amount of temperature needed? Because this will determine how hard the profiles are directly. A little bit hotter or cooler than that then trouble would be stirring.

Not playing favorites here! The mold deserves its fair share of warmth, matching the temperature of our aluminum rod buddy, at a cozy 400-500 degrees Celsius. And don't forget, they both stay toasty after heating.

With everything prepped and piping hot, our mold takes center stage, sliding gracefully into the extrusion machine. The curtain is about to rise on our aluminum spectacle!

Our aluminum rod, now perfectly primed, takes its place at the raw material entrance of the extrusion machine. Some release agents might be sprinkled to ensure our ram and billet don't start sticking like magnets.

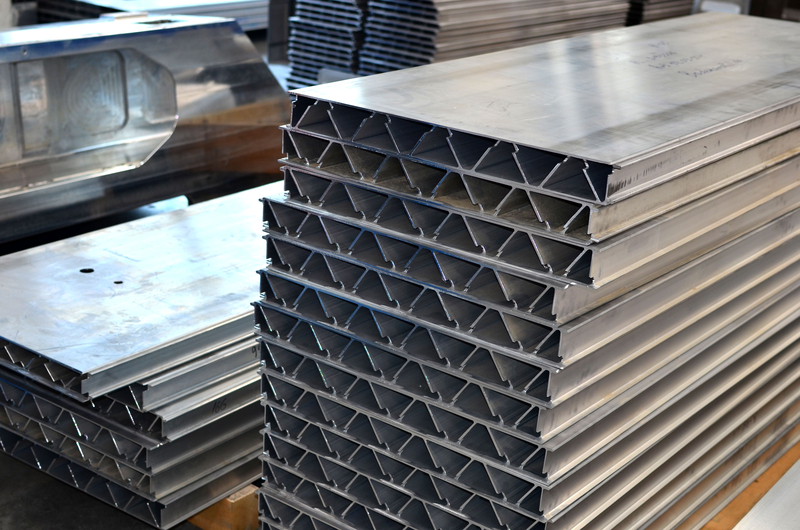

Hold onto your hats, folks! It's the moment we've all been waiting for—the grand entrance of the extruded aluminum profile! As it emerges through the discharge port, we can't help but marvel at its transformation.

Enter stage left: the tractor. Its mission? To gracefully usher the newly minted aluminum profile into the waiting saw, where it'll be chopped into just the right lengths.

After the dramatic cutting act, our aluminum profile takes a breather on the leveling table. Here, it undergoes a bit of straightening and stretching, prepping for its next role—making waves in the finished product area.

Now it's time for the stars to shine! The aluminum profiles gracefully take their positions within the frame then showcase their qualities inside a chamber. They luxuriate in that warmth, for two hours reaching temperatures of 200 degrees Celsius. It's like a rejuvenating spa day for aluminum enhancing its malleability and flexibility.

With the heat treatment completed it's time for the finale—the cooling process. Whether it involves a cooldown or a refreshing gust of air the alloy emerges transformed and ready to embrace possibilities.

So what can we learn from this captivating aluminum extravaganza? Well aluminum extrusion is an art that involves creating custom parts using sectional profiles. It's similar to sculpting clay into shapes. With metal instead. These profiles can be hollow or solid, even semi hollow. Can range from designs, to astonishingly complex ones—all tailor made to fulfill our customers wildest aspirations.

There you have it! The mesmerizing journey of aluminum extrusion concludes as we transform rods into customizable creations—poised to shape the world we inhabit.

From skyscrapers, to cars, aluminum quietly plays a crucial role in the background. Therefore whenever you come across a shining skyscraper or a moving train take a moment to appreciate the process these aluminum structures have gone through to make it all happen. Let's raise a toast to the power of metal craftsmanship!

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden