English

Views: 222 Author: Astin Publish Time: 2025-04-21 Origin: Site

Content Menu

● Introduction to Aluminum Extrusion Profiles

>> Material Properties of Aluminum Extrusion Profiles

● Benefits of Using Aluminum Extrusion Profiles in Construction

>> 1. Lightweight and High Strength

● Common Applications of Aluminum Extrusion Profiles in Construction

● Industrial Applications Beyond Construction

● Future Innovations and Trends

● FAQ

>> 1. What are the primary benefits of using aluminum extrusion profiles in construction?

>> 2. How are aluminum extrusion profiles made?

>> 3. What are some common applications of aluminum extrusion profiles in construction?

>> 4. Can aluminum extrusion profiles be customized for specific projects?

>> 5. Why are aluminum extrusion profiles considered sustainable?

Aluminum extrusion profiles have become a cornerstone in modern construction due to their unique combination of strength, durability, and versatility. These profiles are widely used in various construction applications, from structural components to decorative elements. In this article, we will explore the reasons behind the popularity of aluminum extrusion profiles in construction, their benefits, and how they are transforming the industry.

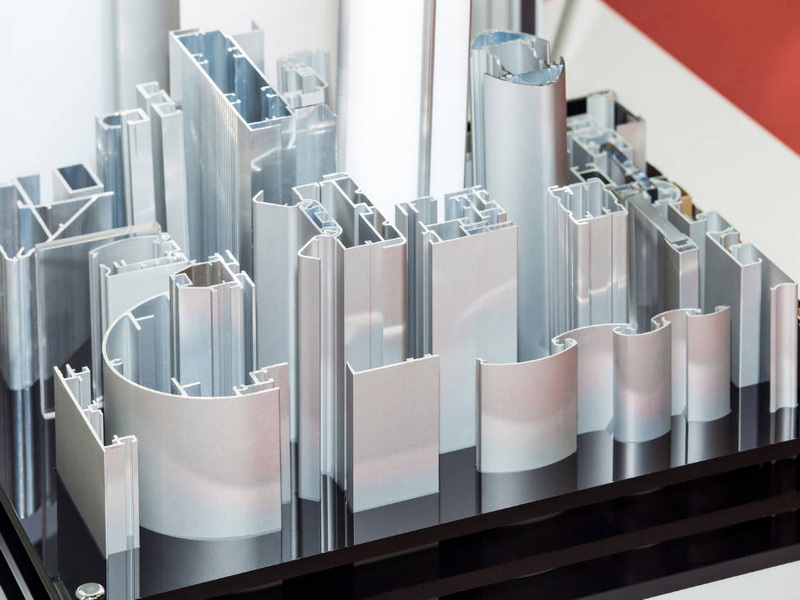

Aluminum extrusion profiles are created through a process where aluminum alloys are shaped into long, uniform profiles with specific cross-sectional shapes. This process involves heating aluminum billets and forcing them through a die to achieve the desired shape[5]. The resulting profiles are lightweight yet strong, making them ideal for a wide range of applications.

Aluminum extrusion profiles derive their versatility from the properties of the aluminum alloy used in their construction. Aluminum is inherently lightweight and possesses good durability and strength. It also forms a protective oxide layer on its surface, which provides excellent resistance to corrosion[1][3]. To enhance these properties, other metals like magnesium, silicon, copper, or zinc are often added during the alloying process. These additions improve the strength, corrosion resistance, and machinability of the aluminum, allowing for intricate shapes to be fabricated[1].

One of the most significant advantages of aluminum extrusion profiles is their lightweight nature combined with high strength. This characteristic allows for easier handling and installation, reducing labor costs and time on site. In structural applications, aluminum extrusion shapes can support substantial loads while remaining significantly lighter than traditional materials like steel or concrete[4]. This property is particularly beneficial in high-rise buildings, where reducing the overall weight of the structure can lead to lower foundation costs and improved seismic performance[4].

Aluminum's natural ability to resist corrosion is due to a protective oxide layer that forms on its surface when exposed to air. This characteristic makes aluminum extrusion profiles an excellent choice for construction projects in harsh environments, such as coastal areas or regions with high humidity[4]. The corrosion resistance of aluminum means that structures can maintain their appearance and structural integrity over time, reducing the need for maintenance and replacement[4].

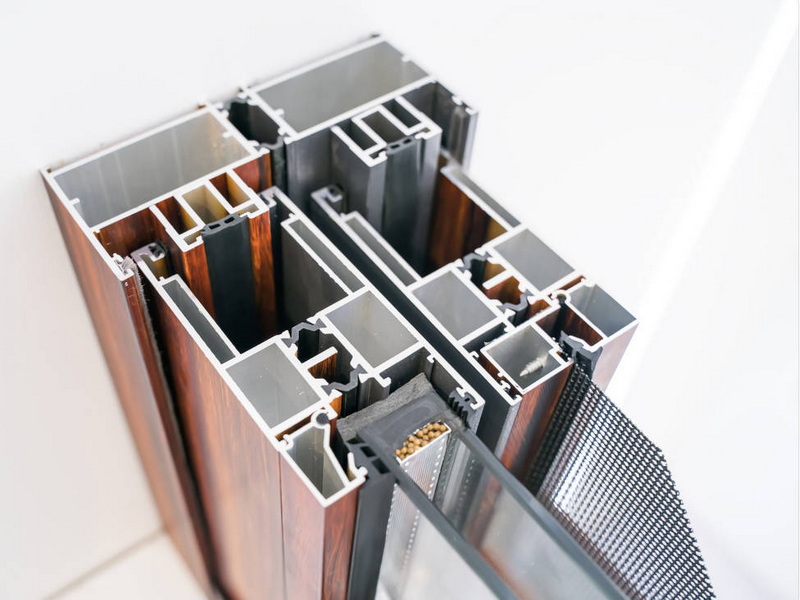

The extrusion process allows for the creation of intricate shapes and designs that can be customized to meet specific project requirements. Architects and designers can take advantage of this flexibility to create unique and aesthetically pleasing structures. Custom aluminum extrusions can be designed to fit specific applications, whether it's for window frames, curtain walls, or decorative elements[4].

While the initial material cost of aluminum extrusion profiles may be higher than some alternatives, the long-term savings associated with reduced maintenance, lower energy consumption, and extended lifespan can outweigh these initial expenses[4]. Additionally, the lightweight nature of aluminum extrusion shapes can lead to savings in transportation and installation costs. The ease of handling and installation reduces labor time, further contributing to overall project savings[4].

Aluminum extrusion profiles are eco-friendly and recyclable, making them a sustainable choice for construction projects. Their recyclability reduces waste and conserves natural resources, aligning with modern sustainable building practices[3].

Aluminum extrusion profiles see widespread use in various construction applications due to their strength, durability, and resistance to corrosion. Common applications include:

- Window and Door Frames: Aluminum extrusions are used for their lightweight yet strong properties, making them ideal for window and door frames.

- Curtain Walls: These profiles are used in curtain walls for their ability to support heavy loads while maintaining a sleek, modern appearance.

- Balcony Railings: Aluminum extrusions provide a durable and corrosion-resistant option for balcony railings.

- Roofing Structures: They are used in roofing structures for their strength and ability to withstand harsh weather conditions.

- Scaffolding: Aluminum scaffolding is lightweight and easy to assemble, making it a popular choice for construction sites.

- Signage Frames: Aluminum extrusions are used for signage due to their durability and resistance to corrosion[1].

Beyond construction, aluminum extrusion profiles find many applications across various industrial sectors. They are commonly used in:

- Transportation Manufacturing: Extrusions form structural components in aircraft, ships, trucks, trains, and more due to their strength and lightweight properties[1].

- Automotive Industry: Aluminum extrusions are used for chassis components, suspension parts, and other load-bearing applications[1].

- Machinery and Equipment Manufacturing: They create frames, housings, and protective guards due to their machinability and durability[1].

- Tooling Applications: Aluminum extrusions are used in tooling due to their precision and durability.

- Renewable Energy Structures: They are used in renewable energy applications for their strength and corrosion resistance[1].

As technology advances, aluminum extrusion profiles are expected to play a significant role in future innovations. With the increasing focus on sustainability and energy efficiency, aluminum's recyclability and thermal conductivity make it an attractive material for modern construction projects. Additionally, advancements in manufacturing processes are allowing for more complex and customized designs, further expanding the potential applications of aluminum extrusion profiles[6].

Aluminum extrusion profiles have become indispensable in the construction industry due to their unique blend of strength, durability, and versatility. Their lightweight nature, corrosion resistance, and design flexibility make them suitable for a wide range of applications, from structural components to decorative elements. As the construction industry continues to evolve, the demand for materials that can meet both aesthetic and functional requirements will drive the continued use and innovation of aluminum extrusion profiles.

- The primary benefits include their lightweight yet strong nature, excellent corrosion resistance, design flexibility, cost-effectiveness, and sustainability.

- Aluminum extrusion profiles are made by heating aluminum billets and forcing them through a die to achieve the desired shape. The process involves several steps, including billet preparation, container heating, die heating, billet loading, extrusion, cooling, stretching, straightening, and cutting to length[5].

- Common applications include window and door frames, curtain walls, balcony railings, roofing structures, scaffolding, and signage frames[1].

- Yes, aluminum extrusion profiles can be customized to meet specific project requirements. The extrusion process allows for the creation of intricate shapes and designs tailored to individual needs[4].

- Aluminum extrusion profiles are considered sustainable due to their recyclability and eco-friendly nature. They reduce waste and conserve natural resources, aligning with modern sustainable building practices[3].

[1] https://jmaluminium.com/exploring-the-world-of-aluminium-extrusion-profiles-what-they-are-and-how-theyre-used/

[2] https://haluminium.com/hoonly-aluminium-extrusion-profile-faq/

[3] https://profiledecor.com/aluminum-extrusion-profiles/

[4] https://www.yjing-extrusion.com/what-are-the-key-benefits-of-using-aluminum-extrusion-profiles-in-construction.html

[5] https://www.tuli-shop.com/blog/aluminum-extrusion-and-applications-guide.html

[6] https://jlcmc.com/blog/aluminum-extrusion-profiles-design-benefits

[7] https://en.alumag.com.cn/news/Top-10-Benefits-of-Buying-Aluminum-Profiles-for-Your-Construction-Project-224.html

[8] https://www.salesmade.co.uk/why-are-aluminium-extrusions-used-in-construction/

[9] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[10] https://kundel.com/some-interesting-facts-about-using-aluminum-extrusion/

[11] https://www.alufabinc.com/why-use-aluminum/

[12] https://edmolimited.co.uk/education/frequently-asked-questions/aluminium-extrusion/

[13] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[14] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[15] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[16] https://www.minalex.com/2021/10/29/10-questions-ask-aluminum-extruder/

[17] https://aec.org/faqs

[18] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[19] https://spectraaluminum.com/frequently-asked-questions-about-aluminum-extrusion/

[20] https://www.aluminiumprofilesraesa.com/en/50728/FAQ.htm

[21] https://profileprecisionextrusions.com/common-questions-answered/

[22] https://zjaluminum-cnc.com/faqs-on-aluminum-extrusion-and-fabrication/

[23] https://vention.io/resources/guides/t-slot-aluminum-extrusion-structure-design-guide-77

[24] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[25] https://profiledecor.com/aluminum-extrusion-profiles/

[26] https://www.alu4all.com/why-aluminum-formwork-profile-is-popular-in-construction/

[27] https://www.hydro.com/profiles/uses-of-aluminum-extrusions

[28] https://www.shapesbyhydro.com/en/design-thinking/extrusion-quick-guide-for-designing-with-aluminium/

[29] https://www.build-review.com/go-to-guide-to-aluminum-extrusion-in-construction/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden