English

Content Menu

● Properties of Aluminum Profiles

>> 5. Environmental Friendliness

● Applications of Aluminum Profiles

● Advanced Applications of Aluminum Profiles

● Innovative Uses in Construction

>> 1. Modular Building Systems

>> 2. Energy-Efficient Designs

● Aluminum Profiles in Renewable Energy Applications

● Future Trends in Aluminum Profile Manufacturing

● Case Studies: Real-World Applications

● FAQs About Aluminum Profiles

>> 1. What is the extrusion process for aluminum profiles?

>> 2. What are the most common alloys used in aluminum profiles?

>> 3. How can aluminum profiles be customized?

>> 4. What is anodizing in aluminum profiles?

>> 5. What industries benefit most from aluminum profiles?

Aluminum profiles, also known as aluminum extrusions, are versatile and durable materials widely used across industries due to their lightweight nature, strength, corrosion resistance, and adaptability. These profiles are created through an extrusion process where heated aluminum is forced through a die to achieve specific cross-sectional shapes. They are available in various forms, ranging from standard shapes like T-slots and U-channels to custom designs tailored for specific applications.

Aluminum profiles have an excellent strength-to-weight ratio. They are about one-third the weight of steel but offer comparable strength, making them ideal for applications requiring reduced weight without compromising durability.

Aluminum naturally forms a protective oxide layer that shields it from corrosion, even in harsh environments. This property makes aluminum profiles suitable for outdoor applications and reduces maintenance costs.

These profiles can be manufactured in various shapes, sizes, and alloys to meet specific project requirements. They are easily machined, cut, drilled, and assembled, providing flexibility for diverse applications.

Aluminum is an excellent conductor of electricity and heat, making it ideal for electrical and thermal applications.

Aluminum is highly recyclable without losing its properties, making it an eco-friendly choice for sustainable projects.

Standard aluminum profiles include common shapes such as flat bars, T-tracks, U-channels, square tubes, and round pipes. These are widely used in construction, furniture manufacturing, and transportation industries.

Custom aluminum profiles are designed for specific applications requiring unique shapes or features. These are often used in specialized industries like aerospace or automotive manufacturing.

T-slot aluminum profiles are modular systems that allow easy assembly and reassembly for evolving needs. They are commonly applied in industrial automation and machinery frameworks.

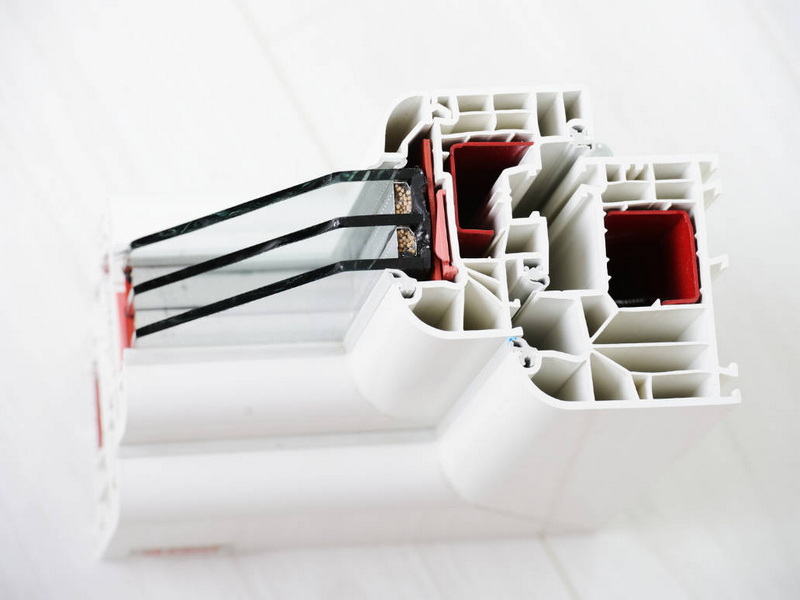

Aluminum profiles are extensively used in building facades, doors, windows, curtain walls, roofing systems, staircases, and decorative panels due to their aesthetic appeal and durability.

In manufacturing industries, aluminum profiles serve as frameworks for assembly lines, conveyor systems, safety enclosures, and robotic mounts.

Lightweight yet strong aluminum profiles are utilized in automotive parts, rail vehicles, and aerospace components to enhance fuel efficiency and performance.

Due to their excellent thermal conductivity, aluminum profiles are often used as heat sinks in electronic devices.

Aluminum profiles contribute to modern furniture designs by providing lightweight yet sturdy frames for tables, chairs, shelves, and display cases.

Aluminum profiles play a critical role in aerospace engineering by enabling the creation of complex shapes that reduce the overall weight of aircraft while maintaining structural integrity. This leads to improved fuel efficiency and performance.

In advanced manufacturing techniques like 3D printing, aluminum profiles serve as lightweight structural components that allow precise designs for prototypes or end-use products.

Aluminum profiles are increasingly used in modular building systems that allow faster assembly and disassembly processes. These systems provide flexibility for temporary structures or buildings requiring frequent modifications.

In modern architecture, aluminum profiles contribute to energy-efficient designs such as passive solar heating systems where they optimize energy use while maintaining aesthetic appeal.

Aluminum profiles play a pivotal role in renewable energy technologies:

- Solar Panel Frames: Their lightweight yet strong nature makes them ideal for supporting solar panels while ensuring durability against environmental factors.

- Wind Turbine Structures: Aluminum's corrosion resistance ensures long-lasting performance in wind turbine components exposed to harsh weather conditions.

The manufacturing of aluminum profiles is evolving with advancements such as:

- Smart Manufacturing: Integration of IoT (Internet of Things) and AI (Artificial Intelligence) allows manufacturers to optimize production processes by reducing waste and improving efficiency.

- Sustainable Practices: Increased emphasis on recycling aluminum to minimize environmental impact while maintaining quality standards.

One notable example is the use of aluminum profiles in constructing the Burj Khalifa—the world's tallest building. Aluminum was chosen for its lightweight properties and corrosion resistance to create the facade and structural elements that withstand extreme weather conditions. This demonstrates the material's versatility across large-scale projects.

Aluminum profiles have revolutionized industries with their unique combination of properties such as lightweight strength, corrosion resistance, versatility, and sustainability. From construction to aerospace engineering and renewable energy applications, these materials continue to shape modern innovation while contributing to environmental goals.

The extrusion process involves heating aluminum billets until they soften and then forcing them through a die to create specific cross-sectional shapes. This method allows manufacturers to produce both standard and custom designs efficiently.

The most commonly used alloys include 6063 and 6005 series due to their excellent extrudability, corrosion resistance, and mechanical properties suitable for various applications like construction or industrial automation.

Customization involves selecting the right alloy based on mechanical requirements (e.g., strength or corrosion resistance), designing the profile shape using CAD software, creating dies for extrusion processes, and applying surface treatments like anodizing or powder coating.

Anodizing is an electrochemical process that enhances the corrosion resistance of aluminum by creating a durable oxide layer on its surface. It also allows the addition of vibrant colors for decorative purposes.

Industries such as construction (doors/windows), transportation (automotive/aerospace), electronics (heat sinks), furniture manufacturing (frames), renewable energy (solar/wind), and industrial automation (machine frameworks) rely heavily on aluminum profiles due to their versatility.

[1] https://www.alutech-aluminium.com/aluminum-profile-an-introduction-and-overview

[2] https://www.chaluminium.com/properties-and-applications-of-aluminum-profiles

[3] https://www.finealuminum.com/blog/properties-and-characteristics-of-aluminum-profiles

[4] https://www.linkedin.com/pulse/what-applications-aluminum-materials-industrial

[5] https://www.aluminumcustom.com/blog-Blog-11407/Top-Ten-Benefits-of-Using-Aluminum-Profiles-for-Your-Next-Construction-Project-11883859.html

[6] https://proax.ca/en/blog/post/aluminum-extrusion-manufacturing-applications

[7] https://haluminium.com/hoonly-aluminium-extrusion-profile-faq/

[8] https://www.reddit.com/r/metalworking/comments/1jaa395/aluminum_profiles_questions/

[9] https://www.framingtech.com/faqs

[10] https://stavianmetal.com/en/what-is-aluminum-profile/

[11] https://www.wj-lean.com/news/the-application-of-industrial-aluminum-profiles-in-various-industries/

[12] https://stacindustry.com/en/processes/main/extruded-profile-machining/

[13] https://www.profall.com/en/what-is-an-aluminum-profile

[14] https://www.piometal.com/faq/

[15] https://www.alu4all.com/faq-about-aluminum-profile-anodizing/

[16] https://www.xingfaindonesia.com/News/The-Properties-of-Aluminium-Profile.html

[17] https://www.comhan.com/en/products/aluminium-profiles-standard

[18] https://blog.item24.com/en/the-item-building-kit-system/aluminium-profile-types-an-overview-of-the-differences/

[19] https://www.alu4all.com/the-difference-and-relation-between-aluminum-profiles-and-aluminum-alloys/

[20] https://www.matara.com/technical-articles/an-introduction-to-aluminium-profiles/

[21] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[22] https://www.otalum.com/the-functions-and-characteristics-of-aluminium-profiles-that-you-dont-know.html

[23] https://www.linkedin.com/pulse/comprehensive-guide-aluminum-profiles-8ek4c

[24] https://www.profall.com/en/blog/aluminum-profiles-the-right-profile-for-every-application

[25] https://www.zahit.com.tr/what-is-aluminum-profile-what-are-its-usage-areas-and-features

[26] https://www.chalcoaluminum.com/blog/aluminum-profile-application/

[27] https://www.zp-aluminium.com/info/applications-of-industrial-aluminum-profiles-80073860.html

[28] https://www.alu4all.com/why-aluminum-formwork-profile-is-popular-in-construction/

[29] https://nalbantal.com/en/understanding-aluminium-profile-production/

[30] https://www.alu-haomei.com/article/t-slot-industrial-aluminum-profiles-for-modern-industries.html

[31] https://www.part-on.co.uk/blog/post/what-are-the-advantages-of-using-aluminum-profiles-in-construction-or-manufacturing/

[32] https://www.krcaluprofiles.com/blog/benefits-of-using-aluminium-profiles-for-cabinet-construction/

[33] https://www.shenghai-alu.com/article/what-are-use-for-industrial-aluminium-profile-9-types.32

[34] https://www.linkedin.com/pulse/application-aluminum-profiles-mechanical

[35] https://orangealuminum.com/blog/five-advantages-of-aluminum-in-construction/

[36] http://ja.gkbmgroup.com/aluminum-profiles-faq/

[37] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[38] https://hmaluprofile.net/faq.html

[39] https://elkamehr.com/en/130-common-questions-answers-about-aluminum/

[40] https://easteelaluprofile.com/faq/

[41] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[42] https://edmolimited.co.uk/education/frequently-asked-questions/aluminium-extrusion/

[43] https://www.reaying-alu.pcd-insert.com/FAQ/FAQ-1.html

[44] https://www.aluminiumprofilesraesa.com/en/50728/FAQ.htm

[45] https://www.sanlev.gr/faq.html

[46] https://www.chaluminium.com/the-most-detailed-knowledge-of-aluminum-profiles

[47] https://kenanmetal.com/aluminum-sigma-profiles-and-features

[48] https://www.gj-alu.com/aluminum-profile/what-is-an-aluminum-profile.html

[49] https://amcaluminum.ph/different-uses-of-aluminum-profiles/

[50] https://www.mornglass.com/the-application-of-aluminium-profiles-in-building.html

[51] https://www.goodssourcing.com/blog/top-10-applications-of-industrial-aluminum-profiles

[52] https://gulsanaluminyum.com/en/the-benefits-of-aluminum-profiles-in-modern-construction/

[53] https://aec.org/faqs

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden