English

Views: 222 Author: Astin Publish Time: 2025-04-10 Origin: Site

Content Menu

● Introduction to Aluminum Box Profiles

● Applications of Aluminum Box Profiles

● Benefits of Aluminum Box Profiles

● Production and Customization

● Environmental Considerations

● Market Trends and Future Outlook

● Challenges and Opportunities

● FAQ

>> 1. What are the common sizes of aluminum box profiles?

>> 2. How are aluminum box profiles joined?

>> 3. What are the benefits of using aluminum box profiles over other metals?

>> 4. Can aluminum box profiles be bent?

>> 5. Are aluminum box profiles recyclable?

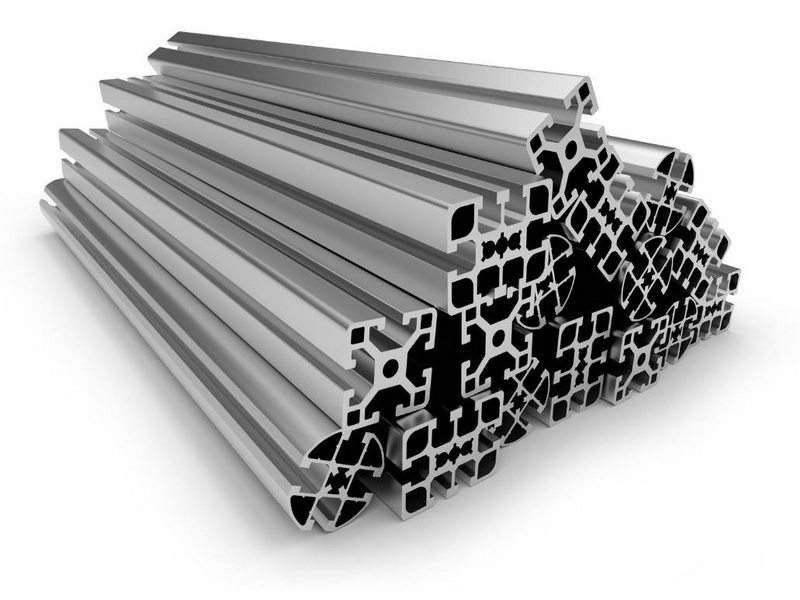

Aluminum box profiles, also known as aluminum box sections or rectangular tubes, are versatile and widely used components in various industries. Their applications span from construction and automotive to furniture and electronics, leveraging their lightweight, durable, and corrosion-resistant properties. This article will delve into the uses, benefits, and applications of aluminum box profiles, exploring their significance across different sectors.

Aluminum box profiles are hollow, rectangular or square tubes that are extruded from aluminum sheets. They are valued for their high strength-to-weight ratio, making them ideal for applications requiring both structural integrity and minimal weight. These profiles are produced in various sizes and wall thicknesses, allowing them to be tailored for specific needs. For instance, they can range from small dimensions like ½” x ½” to larger sizes such as 4” x 4” or even up to 200mm x 200mm, with wall thicknesses varying from 1.6mm to 6mm.

In the construction industry, aluminum box profiles are used extensively for their durability and aesthetic appeal. They are commonly found in:

- Door and Window Frames: Providing structural support while maintaining a sleek appearance.

- Facade Cladding: Offering a modern look while protecting buildings from environmental elements.

- Structural Frames: Used in building structures due to their high strength and lightweight properties.

- Roofing Systems: Aluminum profiles are used in roofing for their durability and resistance to weather conditions.

- Railings and Balustrades: Used for their strength and corrosion resistance, providing safety and visual appeal.

The automotive sector benefits from aluminum box profiles in several ways:

- Vehicle Frames: They contribute to reducing vehicle weight, enhancing fuel efficiency and reducing environmental impact.

- Transport Systems: Used in trailers and containers for their strength and lightweight characteristics.

- Engine Components: Some engine parts are made from aluminum due to its heat conductivity and lightweight properties.

- Interior Components: Aluminum profiles are used in car interiors for structural support and aesthetic purposes.

Aluminum box profiles are also popular in furniture making due to their:

- Structural Integrity: Used in frames for tables, chairs, and shelves.

- Aesthetic Appeal: Providing a modern and sleek appearance for interior designs.

- Outdoor Furniture: Aluminum profiles are ideal for outdoor furniture due to their resistance to corrosion and weather conditions.

- Custom Designs: They allow for flexible design options, enabling the creation of unique furniture pieces.

In the electrical and electronics sector, these profiles are used for:

- Electronic Device Cases: Offering protection and durability for electronic components.

- Distribution Boards: Used for their conductivity and resistance to corrosion.

- Cable Management: Aluminum profiles are used to organize cables and wires in electronic systems.

- Server Racks: Providing structural support and cooling efficiency for server equipment.

1. Lightweight and High Strength: Aluminum box profiles offer a significant strength-to-weight ratio, making them ideal for applications where weight reduction is crucial.

2. Corrosion Resistance: They possess natural resistance to corrosion, extending their lifespan even in harsh environments.

3. Easy Processing: Aluminum can be easily machined, cut, and assembled, allowing for flexible design options.

4. Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice.

5. Cost-Effectiveness: Compared to other metals, aluminum profiles often provide a cost-effective solution for many applications.

Aluminum box profiles are produced through an extrusion process, allowing for complex shapes and precise dimensions. They can be customized in various sizes and finishes to meet specific project requirements. Companies like Metals4U and Metals Warehouse offer custom cutting services, ensuring that customers can purchase only what they need for their projects. Additionally, aluminum profiles can be anodized or powder-coated to enhance their appearance and durability. Anodizing provides a durable, corrosion-resistant finish, while powder coating offers a wide range of colors and textures.

Aluminum is 99% recyclable, making aluminum box profiles a sustainable choice for construction and manufacturing projects. Their lightweight nature also contributes to energy efficiency in transportation and use, further reducing their environmental footprint. The recyclability of aluminum reduces waste and conserves natural resources, aligning with global efforts to reduce carbon emissions and promote sustainable practices.

The demand for aluminum box profiles is expected to grow as industries continue to seek lightweight and durable materials. Advances in technology are also expanding the capabilities of aluminum extrusion, allowing for more complex shapes and designs. This trend is particularly evident in the automotive and aerospace sectors, where weight reduction is critical for improving fuel efficiency and reducing emissions. Additionally, the increasing focus on sustainability will further boost the adoption of aluminum profiles due to their recyclability and energy efficiency.

Despite their numerous benefits, aluminum box profiles face challenges such as competition from other materials like steel and carbon fiber. However, ongoing innovations in aluminum production are addressing these challenges by improving strength and reducing costs. Furthermore, the versatility of aluminum profiles presents opportunities for new applications in emerging industries such as renewable energy and advanced manufacturing.

Aluminum box profiles are versatile components that offer a combination of structural strength, aesthetic appeal, and environmental sustainability. Their applications across various industries highlight their importance in modern construction, manufacturing, and design. As technology continues to evolve, the demand for lightweight yet durable materials like aluminum box profiles is likely to increase, further expanding their usage areas.

- Aluminum box profiles are available in a wide range of sizes, starting from ½” x ½” up to larger dimensions like 4” x 4” or even 200mm x 200mm, with varying wall thicknesses.

- Aluminum box sections can be joined using welding methods such as TIG welding, or more conveniently, by using plastic tube connectors.

- Aluminum box profiles offer advantages such as lightweight properties, excellent corrosion resistance, good conductivity, and cost-effectiveness compared to other metals like brass or steel.

- Yes, aluminum box sections can be bent, but the bending radius may be limited to avoid cracking. Depending on size and thickness, bending can be done manually or may require specialized machinery.

- Yes, aluminum is highly recyclable, making aluminum box profiles an environmentally friendly choice. They are 99% recyclable, contributing to sustainable practices in construction and manufacturing.

[1] https://kenanmetal.com/aluminum-profile-types-and-usage-areas

[2] https://www.profall.com/en/blog/flat-aluminum-profiles-applications-and-advantages

[3] https://www.zahit.com.tr/what-are-the-usage-areas-and-features-of-aluminum-box-profiles

[4] https://www.metalswarehouse.co.uk/a-guide-to-aluminium-box-profiles/

[5] https://www.metals4u.co.uk/materials/aluminium/aluminium-box-section

[6] https://balex.eu/en/knowledge-base/news/advantages-and-applications-of-box-profile-sheets

[7] https://www.chalcoaluminum.com/blog/aluminum-profile-application/

[8] https://www.zahit.com.tr/what-is-aluminum-profile-what-are-its-usage-areas-and-features

[9] https://www.chaluminium.com/top-10-uses-of-aluminum-in-the-construction-industry

[10] https://www.lametals.co.uk/blog/custom-aluminium-profiles-applications/

[11] https://www.lametals.co.uk/blog/the-benefits-of-using-aluminium-in-modern-construction-projects/

[12] https://www.1stchoicemetals.co.uk/category/aluminium/aluminium-box-section/square-tube-box-section/

[13] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[14] https://www.sixaluminium.com/the-benefits-of-using-aluminum-square-tubes-for-construction/

[15] https://blog.item24.com/en/the-item-building-kit-system/aluminium-profile-types-an-overview-of-the-differences/

[16] https://www.cladco.co.uk/sheets/box-profile

[17] https://www.steelroofsheets.co.uk/categories/box-profile-roofing-sheets

[18] https://www.cladco.co.uk/sheets

[19] https://www.profall.com/en/blog/aluminum-profiles-the-right-profile-for-every-application

[20] https://www.goldapple-alu.com/understanding-aluminium-cabinet-profiles-a-comprehensive-guide.html

[21] https://www.profall.com/en/what-is-an-aluminum-profile

[22] https://highways.today/2021/11/24/guide-aluminum-profiles/

[23] https://www.chaluminium.com/properties-and-applications-of-aluminum-profiles

[24] https://www.boschrexroth.com/en/nz/products/product-groups/assembly-technology/topics/aluminum-profiles-solutions-components/

[25] https://www.gj-alu.com/news/choosing-the-right-aluminium-profile.html

[26] https://stavianmetal.com/en/aluminum-profile-box-what-is-it-price-advantages-and-disadvantages-where-to-buy/

[27] https://www.roofgiant.com/blog/news/6-powerful-advantages-of-using-box-profile-roofing-sheets/

[28] https://haluminium.com/hoonly-aluminium-extrusion-profile-faq/

[29] https://www.minalex.com/2021/10/29/10-questions-ask-aluminum-extruder/

[30] https://www.comhan.com/en/blog/customized-aluminum/aluminium-extrusion-5-tips-design-aluminium-profiles-efficiently-and

[31] https://www.cladco.co.uk/faq-and-advice

[32] https://jmaluminium.com/selecting-right-aluminium-profiles/

[33] https://amcaluminum.ph/questions-ask-aluminum-supplier/

[34] https://www.tuli-shop.com/blog/aluminium-profile-load-capacity.html

[35] https://edmolimited.co.uk/education/frequently-asked-questions/aluminium-extrusion/

[36] https://www.linkedin.com/pulse/selection-basic-knowledge-aluminum-profiles-fenan-aluminum-co-ltd

[37] https://www.alu4all.com/why-aluminum-formwork-profile-is-popular-in-construction/

[38] https://profipas.com.ua/en/profiles-en-aluminium-pour-la-construction/

[39] https://www.chaluminium.com/aluminium-section-size-a-guide-to-measurement-and-choose

[40] https://www.khetangroup.net/blog-post/the-ultimate-checklist-for-choosing-aluminum-profiles/

[41] https://kimsen.vn/10-exceptional-benefits-of-aluminum-enclosures-ne74.html

[42] https://www.rightonblackburns.co.uk/aluminium-form-types/aluminium-box-section

[43] https://www.metalreyonu.com.tr/en/products/aluminum-box-profile

[44] https://www.reddit.com/r/metalworking/comments/1jaa395/aluminum_profiles_questions/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden