English

Views: 222 Author: Astin Publish Time: 2025-03-24 Origin: Site

Content Menu

● Understanding Aluminum Profile Angles

>> Types of Aluminum Profile Angles

● Standard Sizes of Aluminum Profile Angle

>> Availability

>> Custom Sizes

>> Considerations for Custom Sizes

● Applications of Aluminum Profile Angle

>> Construction and Architecture

>> Furniture and Interior Design

● Advantages of Using Aluminum Profile Angle

>> Versatility

● How to Choose the Right Aluminum Profile Angle

>> Consider Environmental Factors

>> Select Standard or Custom Size

● FAQ

>> 1. What are the standard sizes of aluminum profile angles?

>> 2. What are aluminum profile angles commonly used for?

>> 3. What are the advantages of using aluminum profile angles?

>> 4. How do I choose the right size of aluminum profile angle for my project?

>> 5. Where can I purchase aluminum profile angles?

Aluminum profile angles are essential components in various industries, offering a unique combination of strength, lightweight properties, and corrosion resistance[8][10][13]. These L-shaped extrusions are used for structural support, framework, edging, and decorative purposes[3][6][8]. Understanding the standard sizes of aluminum profile angles is crucial for engineers, architects, and DIY enthusiasts to ensure the right choice for their specific applications[6].

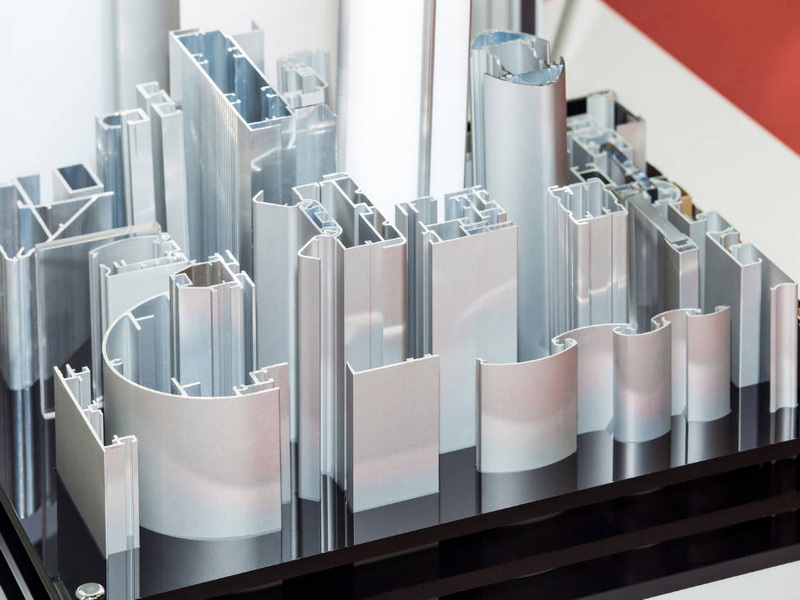

Aluminum angles are L-shaped extrusions formed with a 90-degree angle between two legs[6][8][12]. These profiles are known for their versatility and are widely used in construction, manufacturing, and home improvement projects[3][8][9]. The geometry of aluminum angles provides added strength, making them suitable for frames, trusses, and support structures[8].

Aluminum profile angles are available in two primary configurations[11]:

- Equal Angles: These angles have legs of equal length, providing balanced support and are commonly used for general-purpose applications[1][11].

- Unequal Angles: These angles have legs of different lengths, making them suitable for specialized applications where different support levels are needed on each side[1][11].

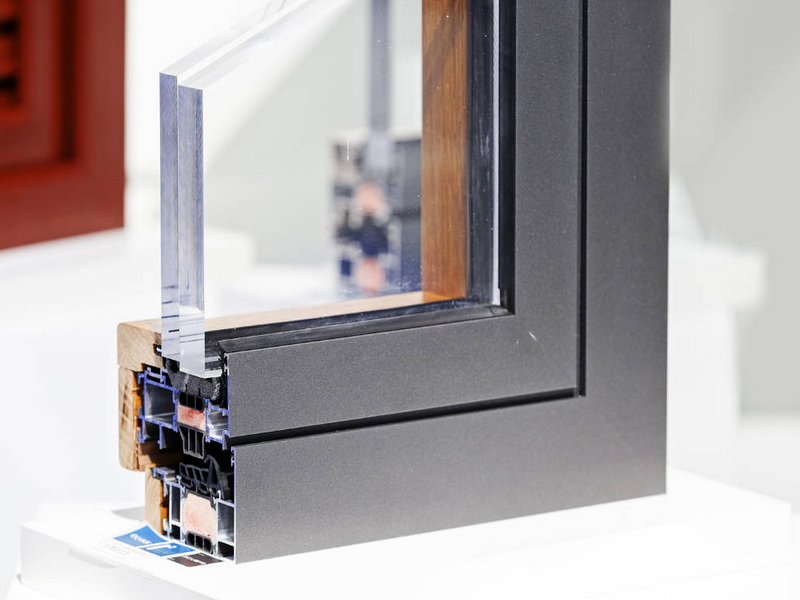

When specifying aluminum profile angles, several key dimensions must be considered[6][12]:

- Leg Length: Refers to the length of each side of the angle. This dimension is critical for determining the load-bearing capacity and structural support provided by the angle[6].

- Thickness: Indicates the thickness of the aluminum material along the legs. Thicker angles offer greater strength and resistance to deformation but also increase weight[6].

- Corner Radii: These are the curved edges at the interior and exterior of the angle. Smaller radii provide sharper angles, while larger radii can reduce stress concentrations and increase strength[6].

Aluminum profile angles are manufactured in a range of standard sizes to meet various construction and industrial requirements[6][12]. These standard sizes offer cost-effectiveness and quicker availability for common applications[12].

- Equal Angles: Standard equal angle sizes typically range from 0.5 inches to 8 inches for leg length, with thicknesses varying from 1/16 inch to 1/2 inch[6][12].

- Unequal Angles: Unequal angles come in a broader range of sizes to accommodate specific needs. Common sizes can range from 0.375 inches x 0.5 inches to 3 inches x 6 inches, with thicknesses between 1/8 inch to 1/4 inch[7].

Here are some common standard sizes for aluminum equal angle bars[1]:

| Leg Length (mm) | Leg Length (mm) | Thickness (mm) |

|---|---|---|

| 10 | 10 | 1 to 2 |

| 12 | 12 | 1 to 2 |

| 15 | 15 | 1 to 3 |

| 20 | 20 | 1 to 4 |

| 25 | 25 | 1.5 to 4 |

| 30 | 30 | 1.5 to 5 |

| 35 | 35 | 1.5 to 4 |

| 40 | 40 | 1.5 to 4 |

| 45 | 45 | 2 to 3 |

| 50 | 50 | 2 to 5 |

Common standard sizes for aluminum unequal angle bars[1]:

| Leg 1 Length (mm) | Leg 2 Length (mm) | Thickness (mm) |

|---|---|---|

| 10 | 5 | 1.5 |

| 12 | 3 or 6 | 1 to 1.2 |

| 15 | 10 | 1 to 2 |

| 19 | 11 | 2 |

| 20 | 10, 15, 18 | 1.5 to 3 |

| 22 | 12 | 2 |

| 25 | 10, 12, 15 | 1.5 to 3 |

| 30 | 10, 11, 12, 15 | 1.5 to 4 |

| 35 | 10, 15, 20, 25 | 1.5 to 4 |

| 40 | 10, 15, 20 | 2 to 4 |

| 50 | 20, 25, 30 | 1.5 to 3 |

| 60 | 30 or 40 | 2 to 4 |

Standard sizes are widely available from aluminum suppliers and metal distributors[6]. These can be purchased in various lengths and cut to specific requirements[11].

For projects with unique requirements, custom aluminum profile angles can be manufactured[3][6]. Custom sizes allow for precise adaptation to specific design needs, ensuring optimal performance and material usage[6].

- Design Specifications: Custom sizes must be precisely specified to ensure they meet the structural and aesthetic requirements of the project[6].

- Manufacturing Process: Custom angles are typically produced through aluminum extrusion, allowing for a wide range of shapes and sizes[13].

- Cost and Lead Time: Custom sizes may involve higher costs and longer lead times compared to standard sizes[12].

Aluminum profile angles are used across various industries due to their beneficial properties[3][4][9].

Aluminum angles are frequently used for structural support, frameworks, and reinforcement in buildings and infrastructure projects[3][4][9]. Their strength-to-weight ratio makes them ideal for roof trusses, wall supports, and edge protection[3][11].

In interior design, aluminum angles serve as decorative framing, edging, and trimming elements[3][4]. They are used in cabinets, shelves, countertops, and picture hanging systems[3].

Aluminum angles are used as heat sinks in electronic devices due to their excellent heat dissipation properties[3][4]. They also serve as structural components in LED lighting fixtures and electrical enclosures[3].

Aluminum angles are employed in retail environments to create signage, modular displays, product stands, and shelving[3][4]. Their durability and aesthetic appeal make them suitable for attracting customers and showcasing products[3].

In the transportation industry, aluminum angles are used in the manufacturing of automobiles, aircraft, and marine vessels[9][11]. Their lightweight and high strength contribute to fuel efficiency and structural integrity[9].

Aluminum angles are popular among DIY enthusiasts for home improvement projects[3]. They can be used as corner protectors, framing, trim work, and brackets[3].

Aluminum profile angles offer several advantages over other materials, making them a preferred choice in many applications[5][10].

Aluminum is a lightweight material with a high strength-to-weight ratio[5][10]. This makes aluminum angles easy to handle and install while providing substantial structural support[10].

Aluminum naturally resists corrosion, making it ideal for outdoor and marine applications[5][13]. It does not rust and can withstand exposure to moisture and harsh environmental conditions[5].

Aluminum angles can be easily cut, drilled, and shaped to meet specific project requirements[5]. They can also be joined using welding or mechanical fasteners[5].

Aluminum angles are available in various sizes, shapes, and finishes, making them versatile for different design styles and functional needs[10][13]. Custom sizes can also be manufactured for specialized applications[6].

Aluminum is a sustainable material that can be recycled indefinitely without losing its properties[10]. This makes aluminum angles an environmentally responsible choice for construction and manufacturing[10].

Selecting the correct aluminum angle involves several considerations to ensure optimal performance and longevity[6][11].

Identify the specific purpose of the aluminum angle[3][4][9]. Consider whether it will be used for structural support, decorative trim, or a combination of both[3][4][6].

Calculate the load the aluminum angle needs to support[6]. This will help determine the required leg length and thickness[6][12].

Evaluate the environmental conditions the aluminum angle will be exposed to[5][13]. For outdoor applications, corrosion resistance is a critical factor[5].

Select an appropriate aluminum alloy based on strength, corrosion resistance, and workability requirements[6]. Common grades include 6061, 6063, and 5052[13].

Decide whether a standard size will suffice or if a custom size is necessary[6][12]. Custom sizes offer greater flexibility but may involve higher costs and longer lead times[12].

Ensure the selected aluminum angle meets relevant industry standards and regulations[11]. This is particularly important for structural applications[11].

Aluminum profile angles are versatile and essential components in modern construction, manufacturing, and DIY projects. Knowing the standard sizes, types, and applications of aluminum angles allows professionals and hobbyists to make informed decisions, ensuring structural integrity, aesthetic appeal, and long-term performance. Whether using standard sizes for cost-effectiveness or custom sizes for specific design needs, aluminum profile angles provide a reliable and adaptable solution for a wide range of applications.

Aluminum profile angles come in various standard sizes, with leg lengths typically ranging from 0.5 inches to 8 inches for equal angles and varying dimensions for unequal angles. Thicknesses generally range from 1/16 inch to 1/2 inch[6][12].

Aluminum profile angles are commonly used for structural support, framing, edging, and decorative purposes in construction, furniture, electronics, retail, and transportation industries[3][4][9].

Aluminum profile angles are lightweight, strong, corrosion-resistant, easy to work with, versatile, and eco-friendly, making them a preferred choice over other materials[5][10].

To choose the right size, consider the application, load requirements, environmental factors, alloy type, and whether a standard or custom size is needed[6][11].

Aluminum profile angles can be purchased from metal suppliers, distributors, and online retailers. Custom sizes can be ordered from manufacturers specializing in aluminum extrusion[6][12].

[1] https://www.profall.com/en/aluminum-angle-sizes

[2] https://www.1stchoicemetals.co.uk/category/aluminium/angles-equal/

[3] https://orangealuminum.com/blog/5-unique-applications-of-aluminum-angle-profiles/

[4] https://www.sixaluminium.com/the-applications-of-aluminum-equal-angle-profiles/

[5] https://www.sixaluminium.com/the-advantages-of-using-aluminum-angles-unequal-profiles/

[6] https://www.alu-haomei.com/article/aluminum-angle-size-specifications-guide.html

[7] https://eagle-aluminum.com/products/angles/angles-18-wall-thickness/

[8] https://www.jagdishmetalindia.com/blog/everything-you-need-to-know-about-aluminium-angle/

[9] https://www.sixaluminium.com/common-applications-of-aluminum-angles-unequal-profiles/

[10] https://www.sixaluminium.com/the-advantages-of-aluminum-equal-angle-profiles/

[11] https://www.mgmetals.co.uk/how-to-choose-the-right-aluminium-angle-for-your-project/

[12] https://endura-steel.com/guide-to-aluminum-angles/

[13] https://www.aluminiumwarehouse.co.uk/blogs/news/why-are-aluminium-angle-profiles-important

[14] http://coastaluminum.com/wp-content/uploads/pdfs/09%20Aluminum%20Angle%206061%20American%20Standard.pdf

[15] https://www.aluminiumtrading.co.za/aluminium-extrusions/equal-angles/

[16] https://www.capral.com.au/extrusion-plate-sheet/extrusion/angles-geometrics/angles/

[17] https://indianextrusions.com/aluminium-extrusion/2428/angle-and-t-profile-pipe-aluminum-section/

[18] https://www.alumeco.com/aluminium/profiles--tubes/angle-profile/g/20

[19] https://extrude-a-trim.com/product-category/angle/

[20] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[21] https://www.aluminiumprofilesraesa.com/en/50728/FAQ.htm

[22] https://www.alu4all.com/faq-about-aluminum-profile-anodizing/

[23] https://mcrealit.com/standard-profiles/

[24] https://www.onlinemetals.com/en/buy/aluminum-angle

[25] https://ezimetal.com.au/blog/aluminium-angle-building-structures/

[26] https://eleanoraluminium.com/blog/aluminium-angles-and-channels/

[27] https://www.practicalmachinist.com/forum/threads/why-arent-structural-aluminum-angles-90-degrees.87208/

[28] https://www.shapesbyhydro.com/en/design_thinking/six-questions-for-an-effective-snap-fit-joint/

[29] http://scaluminum.com/2018/10/beyond-rod-bar-aluminum-whats-standard-aluminum-extrusion/

[30] https://engineering.stackexchange.com/questions/32782/how-do-i-to-connect-aluminium-profiles-with-60-and-120-degree-angles

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden