English

Views: 222 Author: Astin Publish Time: 2025-04-25 Origin: Site

Content Menu

● Understanding Aluminum Extrusion Tube Profiles

>> Types of Aluminum Extrusion Profiles

● Key Benefits of Aluminum Extrusion Tube Profiles

>> 1. Exceptional Strength-to-Weight Ratio

>> 3. Precision and Consistency

>> 4. Design Flexibility and Customization

>> 5. Lightweight and Easy Handling

>> 6. Excellent Thermal and Electrical Conductivity

>> 8. Versatility Across Industries

>> 9. Eco-Friendly and Recyclable

>> 10. Ease of Assembly and Maintenance

● The Aluminum Extrusion Tube Manufacturing Process

● Common Applications of Aluminum Extrusion Tube Profiles

● Comparing Aluminum Extrusion Tubes to Other Materials

● Design Considerations for Aluminum Extrusion Tubes

● FAQs About Aluminum Extrusion Tube Profiles

>> 1. What industries benefit most from aluminum extrusion tube profiles?

>> 2. How does the extrusion process affect the strength of aluminum tubes?

>> 3. Can aluminum extrusion tubes be customized for specific applications?

>> 4. What surface finishes are available for extruded aluminum tubes?

>> 5. Are aluminum extrusion tubes environmentally friendly?

Aluminum extrusion tube profiles have revolutionized modern engineering, construction, transportation, and countless other industries. Their unique combination of lightweight strength, corrosion resistance, design flexibility, and cost-effectiveness makes them indispensable for manufacturers and designers worldwide. This article explores the core benefits of aluminum extrusion tube profiles, delves into their manufacturing process, highlights their diverse applications, and answers frequently asked questions to provide a comprehensive understanding of their value.

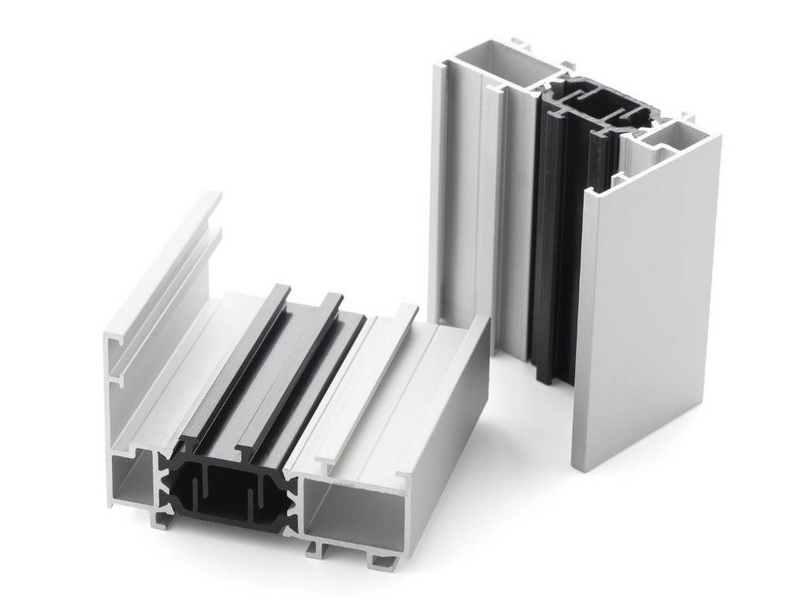

Aluminum extrusion tube profiles are hollow, tubular shapes produced by forcing heated aluminum billets through a die of the desired cross-section. This process allows for the creation of tubes with consistent dimensions, smooth surfaces, and complex geometries, tailored to specific application requirements[4][6][11].

- Solid Profiles: No enclosed cavities; ideal for strength and simplicity.

- Hollow Profiles: One or more enclosed voids, such as tubes and pipes, used for frameworks and channels.

- Semi-Hollow Profiles: Partially enclosed voids, balancing strength and weight.

- Custom Profiles: Unique shapes designed for specialized applications[4][11].

Aluminum extrusion tubes are renowned for their high strength relative to their weight. Aluminum's density is about one-third that of steel, yet its strength can be tailored through alloy selection and heat treatment. This makes extruded tubes ideal for applications where minimizing weight without compromising structural integrity is crucial, such as in aerospace, automotive, and transportation industries[2][7][10].

Aluminum naturally forms a thin oxide layer that protects it from corrosion. Extruded tubes are highly resistant to water, salt, chemicals, and various environmental factors, making them suitable for outdoor, marine, and industrial applications. Additional surface treatments like anodizing or powder coating further enhance this resistance and extend product lifespan[2][3][9][10].

The extrusion process ensures precise dimensional tolerances and consistent quality across large production runs. This precision is vital for applications requiring tight fit and alignment, such as modular framing systems, machinery, and electronics housings[2][3][6].

Aluminum's malleability allows for the creation of nearly unlimited tube shapes and sizes. Complex cross-sections, internal channels, mounting features, and decorative elements can be integrated into a single profile, reducing the need for secondary machining and assembly. Custom dies are relatively inexpensive, enabling cost-effective production of specialized components[4][7][9].

Aluminum extrusion tubes are significantly lighter than steel or copper alternatives. This reduces transportation costs, simplifies installation, and improves the ergonomics of finished products. Lightweight structures are especially valuable in automotive, aerospace, and portable consumer goods[2][3][7][10].

Aluminum conducts heat and electricity efficiently, making extruded tubes ideal for heat exchangers, radiators, electrical enclosures, and LED housings. Their non-magnetic properties also make them suitable for sensitive electronic applications[3][10][12].

Aluminum extrusion is a highly efficient manufacturing process with minimal material waste. The cost of extrusion dies is lower than for other forming methods, and the ability to produce near-net shapes reduces the need for extensive machining. Compared to stainless steel, extruded aluminum tubes can be up to 70% less expensive[7][9].

Aluminum extrusion tubes are used in construction (window frames, curtain walls, structural supports), transportation (vehicle frames, railings), electronics (heat sinks, housings), consumer goods (furniture, sports equipment), and more. Their adaptability to various finishing options and assembly methods makes them suitable for both functional and decorative purposes[3][6][8][12].

Aluminum is 100% recyclable without loss of properties. The extrusion process itself is energy-efficient, and recycled aluminum requires only a fraction of the energy needed for primary production. This makes aluminum extrusion tubes a sustainable choice for environmentally conscious projects[2].

Modular systems built from extruded aluminum tubes can be quickly assembled and disassembled using connectors and fasteners. The corrosion resistance of aluminum reduces maintenance needs, and surface treatments provide additional protection and aesthetic appeal[2][9].

The process of creating aluminum extrusion tube profiles involves several key steps:

1. Billet Preparation: Aluminum billets are heated to a malleable state.

2. Extrusion: The billet is forced through a die with the desired cross-section using a hydraulic press.

3. Cooling: The extruded tube is rapidly cooled to retain its shape and properties.

4. Stretching: The profile is stretched to straighten it and relieve internal stresses, ensuring dimensional accuracy[5].

5. Cutting and Finishing: Tubes are cut to length and may undergo additional processes such as anodizing, painting, or machining for specific applications[3][6][11].

- Construction: Window and door frames, curtain walls, scaffolding, handrails, and structural supports[6][8][12].

- Transportation: Automotive frames, railings, aircraft fuselages, marine structures, and bicycle frames[3][10][12].

- Electronics: Heat sinks, enclosures, LED housings, and cable management systems[3][10][12].

- Industrial Automation: Machine frames, conveyor systems, workstations, and protective guards[6][8].

- Consumer Goods: Furniture, sports equipment, appliances, and decorative trims[3][8].

Aluminum extrusion tubes offer several advantages over traditional materials like steel, copper, or plastics:

- Weight: Aluminum is lighter than steel and copper, reducing overall structure weight[7].

- Corrosion Resistance: Superior to steel, especially in outdoor or marine environments[3][10].

- Cost: Lower material and tooling costs compared to stainless steel[7][9].

- Design Flexibility: More complex shapes and features are possible with extrusion[4][7].

- Recyclability: Aluminum is more easily recycled than most metals and plastics[2].

Aluminum extrusion tubes can be finished in a variety of ways to enhance appearance, durability, and performance:

- Anodizing: Increases corrosion resistance and allows for color customization[7][9].

- Powder Coating: Provides a durable, colorful finish.

- Electrophoretic Coating: Adds further protection and aesthetic options.

- Mechanical Finishing: Brushing, polishing, or sandblasting for texture and shine[9].

When designing with aluminum extrusion tubes, several factors should be considered:

- Alloy Selection: Different alloys offer varying strength, ductility, and corrosion resistance[3][6].

- Wall Thickness: Impacts strength, weight, and thermal properties.

- Tolerance Requirements: Extrusion can achieve tight tolerances, but complex shapes may affect precision[1][5].

- Bending and Forming: Some profiles can be bent or formed post-extrusion, but design and alloy choice affect feasibility[5].

- Assembly Methods: Tubes can be joined by welding, bolting, or using specialized connectors[2][3].

Aluminum extrusion tube profiles offer a compelling combination of strength, lightweight construction, corrosion resistance, and design versatility. Their cost-effectiveness, ease of customization, and environmental benefits make them a preferred material across diverse industries. Whether you are designing structural frameworks, automotive components, electronic housings, or consumer products, aluminum extrusion tubes provide solutions that balance performance, durability, and sustainability.

By understanding the benefits and possibilities of aluminum extrusion tube profiles, engineers, architects, and manufacturers can make informed decisions that drive innovation and efficiency in their projects.

Aluminum extrusion tube profiles are widely used in construction, transportation, electronics, industrial automation, and consumer goods. Their lightweight strength, corrosion resistance, and design flexibility make them ideal for applications ranging from building frameworks to automotive components and heat sinks[3][6][8][12].

The extrusion process enhances the strength of aluminum tubes by creating a homogeneous structure with fewer internal defects. The material is formed under pressure, resulting in increased strength and wear resistance compared to cast or machined parts[1][10].

Yes, aluminum extrusion tubes can be produced in custom shapes, sizes, and alloys to meet unique project requirements. Custom dies are relatively inexpensive, allowing for the integration of specialized features such as mounting channels, internal partitions, or decorative elements[4][7][9].

Common surface finishes include anodizing (for corrosion resistance and color options), powder coating (for durability and aesthetics), and electrophoretic coating. Mechanical finishes like brushing or polishing are also available for specific visual or tactile effects[7][9].

Yes, aluminum is highly recyclable, and the extrusion process is energy-efficient. Recycled aluminum retains its properties, making extruded tubes a sustainable choice for eco-conscious projects. The use of recycled material also reduces environmental impact and resource consumption[2].

[1] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[2] https://www.eztube.com/why-extruded-square-tubes-are-great-for-construction/

[3] https://www.profall.com/en/blog/aluminum-tube-profiles-choose-profall-s-quality

[4] https://jlcmc.com/blog/aluminum-extrusion-profiles-types-applications-quality

[5] https://aec.org/faqs

[6] https://www.gj-alu.com/news/aluminum-extrusion-profiles-and-their-applications.html

[7] https://profileprecisionextrusions.com/why-aluminum-extrusions-are-better-than-stainless-steel-6-reasons-to-choose-aluminum-over-stainless/

[8] https://rpmindinc.com/aluminum-extrusions-uses-and-applications/

[9] https://www.otalum.com/several-significant-advantages-of-aluminum-extruded-profiles.html

[10] https://www.chaluminium.com/extruded-aluminum-tubes-manufacturing-applications-and-advantages

[11] https://www.linkedin.com/pulse/frequently-asked-questions-aluminium-extrusions-how-richard-hart

[12] https://www.hydro.com/profiles/uses-of-aluminum-extrusions

[13] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[14] https://blog.item24.com/en/the-item-building-kit-system/aluminium-profile-types-an-overview-of-the-differences/

[15] https://www.hydro.com/us/us/aluminum/products/extruded-profiles/north-america-resources/extruded-aluminum-products/uses-of-aluminum-extrusions/

[16] https://qst-corp.com/2024/01/12/aluminum-extrusion-parts-and-hardness/

[17] https://www.flexpipeinc.com/ca_en/pipes-and-joints-systems-vs-t-slot-aluminium-profiles-comparing-modular-systems/

[18] https://www.chaluminium.com/properties-and-applications-of-aluminum-profiles

[19] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[20] https://profileprecisionextrusions.com/extruded-vs-seamless-drawn-aluminum-tubes-choosing-the-right-type-for-your-needs/

[21] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[22] https://www.hydro.com/en/global/aluminium/products/extruded-profiles/aluminium-extrusions-in-use/extrusions-for-big-sized-applications/

[23] https://www.comhan.com/en/products/aluminium-profiles-standard

[24] https://www.hy-aluminum.com/news/17.html

[25] https://edmolimited.co.uk/education/frequently-asked-questions/aluminium-extrusion/

[26] https://www.uniqueextrusions.com/aluminum-extrusion-faq/

[27] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[28] https://profileprecisionextrusions.com/5-initial-questions-ask-aluminum-extruder/

[29] https://community.xometry.com/kb/articles/761-metal-extrusion-frequently-asked-questions

[30] https://simmal.com/10-surprising-uses-for-aluminium-extrusion-you-didnt-know/

[31] https://haluminium.com/hoonly-aluminium-extrusion-profile-faq/

[32] https://profileprecisionextrusions.com/common-questions-answered/

[33] https://www.gabrian.com/aluminum-extrusion-alloys/

[34] https://www.gabrian.com/aluminium-extrusions/industries/

[35] https://spectraaluminum.com/frequently-asked-questions-about-aluminum-extrusion/

[36] https://anglelock.com/blog/t-slot-aluminum-strength-vs-welding

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden