English

Views: 222 Author: Astin Publish Time: 2025-03-20 Origin: Site

Content Menu

● Understanding Aluminum Profiles

>> 3. Material Quality and Alloy

>> 5. Thickness and Load-Bearing Capacity

● Using an Aluminum Profile Catalog

● Benefits of Aluminum Profiles

● Environmental Considerations

● FAQ

>> 1. What are the common types of aluminum profiles?

>> 2. How do I choose the right aluminum alloy for my project?

>> 3. What are the benefits of using aluminum profiles?

>> 4. How do I ensure the aluminum profile fits my project's size and shape requirements?

>> 5. What surface finishes are available for aluminum profiles?

Choosing the right aluminum profile from a catalog can be a daunting task, especially with the vast array of options available. Aluminum profiles are versatile and widely used in various industries, including construction, manufacturing, and electronics, due to their lightweight, corrosion-resistant, and durable properties. This article will guide you through the key factors to consider when selecting an aluminum profile from a catalog, ensuring that you make an informed decision tailored to your project's specific needs.

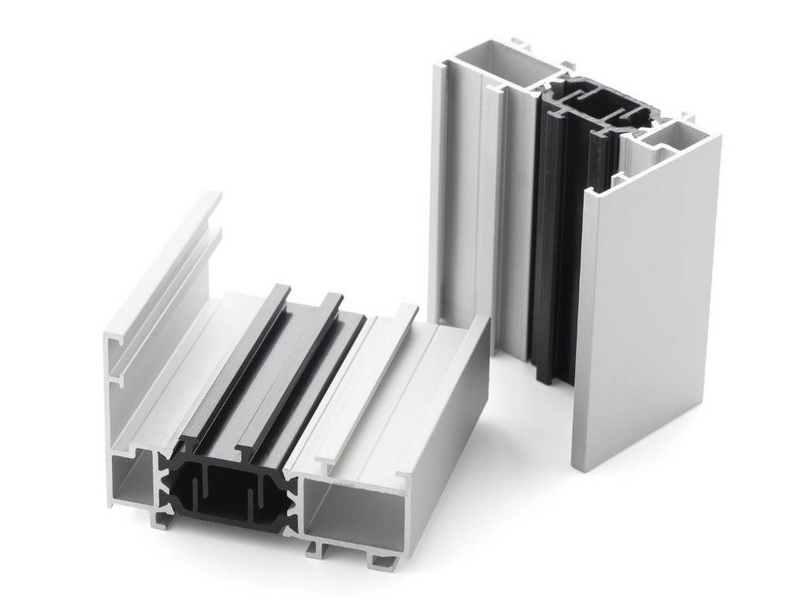

Aluminum profiles are extruded shapes made from aluminum, offering a wide range of applications due to their strength-to-weight ratio, corrosion resistance, and aesthetic appeal. They come in various shapes, sizes, and finishes, making them suitable for both structural and decorative purposes. Whether you are working on a construction project, manufacturing equipment, or designing furniture, aluminum profiles can be tailored to meet specific requirements.

1. Standard Profiles: These include common shapes like angles, channels, and tubes. They are versatile and often used in structural and framework applications.

2. Custom Profiles: Tailored to specific needs, custom profiles offer flexibility in design but may require more time and cost.

3. Modular Profiles: Designed for easy assembly and reconfiguration, modular profiles are ideal for creating adjustable structures or workstations.

When selecting an aluminum profile from a catalog, several factors must be considered to ensure that the chosen profile meets your project's requirements.

Understanding the purpose of the aluminum profile is crucial. Are you looking for structural support, decorative elements, or something that combines both? Different projects require different types of profiles. For instance, if you need high strength and load-bearing capacity, thicker and stronger profiles are recommended.

The size and shape of the aluminum profile are essential for its functionality and aesthetics. Ensure that the dimensions and thickness are adequate to handle the required load and fit within the designated space. Profiles come in various shapes, including square, rectangular, round, and more complex designs.

Aluminum profiles are available in different alloys, each with unique properties:

- 6061 Aluminum Alloy: Known for its high strength and medium corrosion resistance.

- 3003 Aluminum Alloy: Ideal for corrosion resistance but less strong than 6061.

- 6063 Aluminum Alloy: Often used for architectural applications due to its excellent corrosion resistance and surface finish.

The finish on an aluminum profile affects its appearance and durability. Common finishes include raw, anodized, and painted. Anodizing enhances corrosion resistance and provides a durable surface, while powder coating offers more color options and a smoother finish.

The thickness of the aluminum profile directly impacts its strength. Ensure that the profile can handle the load it will bear without bending or warping. Thicker profiles are generally stronger but may add weight.

Choose a trustworthy supplier known for high-quality products and competitive pricing. Consider the cost-effectiveness of the profile in relation to its performance and durability.

An aluminum profile catalog provides a comprehensive overview of available profiles, including their dimensions, materials, and finishes. Here's how to effectively use a catalog:

1. Identify Your Needs: Determine the purpose, size, shape, and material requirements of your project.

2. Browse the Catalog: Look for profiles that match your project's specifications.

3. Check Specifications: Verify the dimensions, alloy, and finish of the profile.

4. Consider Custom Options: If standard profiles do not meet your needs, explore custom profile options.

Aluminum profiles offer several benefits that make them a preferred choice in many industries:

- Durability and Strength: Aluminum is strong and durable, capable of withstanding harsh conditions.

- Lightweight: Easy to handle and install, reducing the overall weight of structures.

- Versatility: Can be extruded into various shapes and sizes, offering design flexibility.

- Aesthetic Appeal: Can be anodized or powder coated in a range of colors for a sleek appearance.

Successful projects using aluminum profiles demonstrate their versatility and effectiveness:

- The Burj Khalifa: Uses aluminum profiles for its exterior, showcasing their ability to withstand extreme conditions.

- The Eden Project: Utilizes aluminum profiles to create large, lightweight greenhouses.

- Automotive Industry: Aluminum profiles are used in car manufacturing to reduce vehicle weight while maintaining strength.

Aluminum profiles are also used in advanced applications such as:

- Renewable Energy Systems: Used in solar panel frames and wind turbine components due to their durability and resistance to corrosion.

- Aerospace Industry: Utilized for aircraft components due to their high strength-to-weight ratio.

- Medical Equipment: Used in medical devices where hygiene and corrosion resistance are critical.

In recent years, there has been an increased focus on sustainability and environmental impact. Aluminum profiles are recyclable, which reduces waste and conserves resources. Additionally, using aluminum can lead to energy savings in transportation and construction due to its lightweight nature.

As technology advances, aluminum profiles are likely to see further innovations in design and application. Trends include the integration of smart materials and the development of more efficient manufacturing processes. These advancements will expand the potential uses of aluminum profiles in various industries.

Choosing the right aluminum profile from a catalog requires careful consideration of several factors, including purpose, size, shape, material quality, surface finish, thickness, and supplier. By understanding these factors and utilizing an aluminum profile catalog effectively, you can select profiles that meet your project's specific needs, ensuring durability, efficiency, and cost-effectiveness. Whether you are working on a small-scale project or a large industrial application, aluminum profiles offer versatility and reliability.

- Common types include standard profiles (angles, channels, tubes), custom profiles, and modular profiles designed for easy assembly.

- Select an alloy based on your project's requirements for strength, corrosion resistance, and machinability. For example, 6061 is strong, while 3003 offers better corrosion resistance.

- Aluminum profiles are durable, lightweight, versatile, and offer aesthetic appeal. They are resistant to corrosion and can be easily customized.

- Measure your project's dimensions carefully and match them with the specifications in the aluminum profile catalog. Consider custom profiles if standard sizes do not fit.

- Common finishes include raw, anodized, and painted. Anodizing enhances durability, while powder coating offers more color options.

[1] https://www.sixaluminium.com/how-to-choose-the-right-aluminum-u-profile-for-your-project/

[2] https://www.khetangroup.net/blog-post/the-ultimate-checklist-for-choosing-aluminum-profiles/

[3] https://jmaluminium.com/selecting-right-aluminium-profiles/

[4] https://www.pailian-aluminium.com/news/how-to-choose-aluminium-profiles-68719816.html

[5] https://www.mebel-alu.com/knowledges_post/case-studies-successful-projects-using-aluminum-edge-profiles/

[6] https://extrude-a-trim.com/aluminum-extrusions-catalog/

[7] https://www.retop-industry.com/news/aluminium-alloy-profiles.html

[8] https://www.premiumparts.com/blog/7-factors-to-consider-in-aluminium-profile-selection

[9] https://www.mebel-alu.com/knowledges_post/case-studies-successful-projects-using-aluminum-frame-profiles/

[10] https://www.alstrut.com/uploads/products/pdf/16395584449Aluminium_Profile_System_Product_Catalog_Alstrut.pdf

[11] https://www.linkedin.com/pulse/design-tips-considerations-aluminium-profiles-bwcprofiles

[12] https://www.aluminium-profile.co.uk/media/KJN_BROCHURE_2018.pdf

[13] https://www.gapengineering.com.au/blog/which-size-profile-is-the-right-one-for-my-project/

[14] https://blog.knottsco.com/blog/bid/26913/Choosing-The-Correct-80-20-Aluminum-Extrusion-for-Your-Application

[15] https://www.profall.com/en/blog/aluminum-profiles-the-right-profile-for-every-application

[16] https://www.fortune-alu.com/info-detail/select-the-right-aluminum-profile

[17] https://www.profall.com/en/what-is-an-aluminum-profile

[18] https://www.wb-aluminum.com/page/faqs-from-aluminum-profile-factory-supplier

[19] https://haluminium.com/hoonly-aluminium-extrusion-profile-faq/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden