English

Views: 222 Author: Astin Publish Time: 2025-04-05 Origin: Site

Content Menu

● Introduction to Aluminum Alloy Profiles

● Introduction to Steel Profiles

>> Strength and Load-Bearing Capacity

● Applications of Aluminum and Steel Profiles

>> Aluminum vs. Steel in Construction

>> Aluminum vs. Steel in Automotive Manufacturing

● Innovations in Aluminum and Steel Manufacturing Processes

● Expert Opinions on Material Selection

● Future Trends in Aluminum and Steel Usage

● Environmental Considerations

● FAQ

>> 1. What are the primary advantages of aluminum alloy profiles?

>> 2. How does the strength of aluminum compare to steel?

>> 3. What are the environmental benefits of using aluminum profiles?

>> 4. In what scenarios is steel preferred over aluminum?

>> 5. How does the cost of aluminum compare to steel?

When comparing the durability of aluminum alloy profiles with steel, several factors come into play, including strength, corrosion resistance, weight, and cost. Both materials have their unique advantages and disadvantages, making them suitable for different applications. In this article, we will delve into the specifics of each material to understand their durability and suitability for various projects.

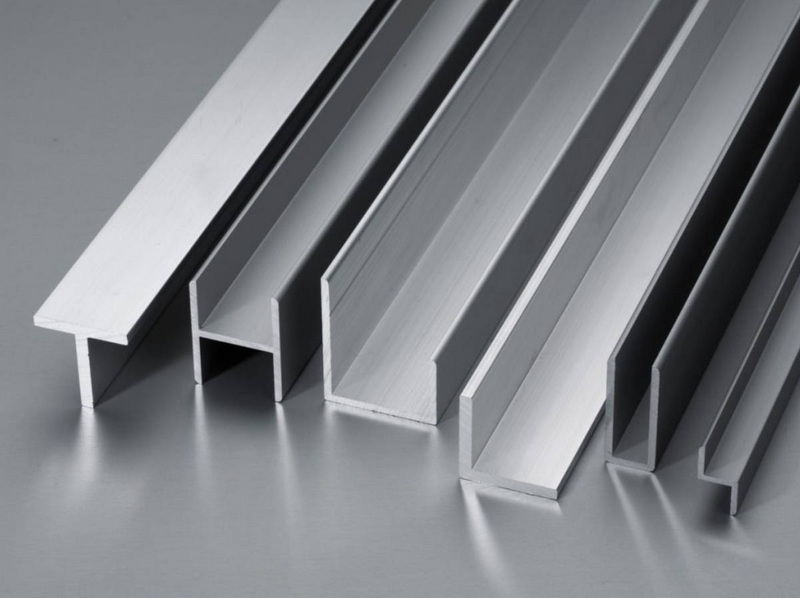

Aluminum alloy profiles are widely used in construction and manufacturing due to their lightweight nature, excellent corrosion resistance, and ease of fabrication. These profiles are formed from aluminum billets and can be processed into various shapes and specifications using methods like extrusion, rolling, and forging. Aluminum's natural oxide layer provides a protective barrier against corrosion, making it ideal for environments with high humidity or exposure to corrosive substances.

Steel profiles, on the other hand, are renowned for their high strength, durability, and ability to withstand heavy loads. Steel is denser and heavier than aluminum, which provides stability and resistance to bending or warping, making it a preferred choice for structural elements in construction projects. However, regular steel is more susceptible to rust and corrosion, requiring protective coatings to maintain its integrity in harsh environments.

Steel generally has a higher tensile strength than aluminum, ranging from 400 to over 2000 MPa, compared to aluminum's range of 70 to 700 MPa. This makes steel more suitable for applications requiring high load-bearing capacity, such as skyscrapers and bridges. Aluminum, while not as strong, offers a superior strength-to-weight ratio, making it ideal for applications where weight reduction is critical, such as in aerospace and automotive industries.

Aluminum naturally forms a protective oxide layer that provides excellent corrosion resistance, reducing the need for additional protective treatments and lowering long-term maintenance costs. Steel, unless it is stainless, is more prone to corrosion and requires regular maintenance to prevent degradation. Stainless steel, with its high chromium content, offers superior corrosion resistance but at a higher cost.

Aluminum is significantly lighter than steel, with a density of about 2.7 g/cm³ compared to steel's 7.9 to 8.0 g/cm³. This lightweight nature simplifies logistics, reduces transportation costs, and eases installation processes. Steel's heavier weight increases shipping costs and requires more robust machinery for handling.

Aluminum is generally more expensive than steel due to its production process and properties. However, aluminum's lower maintenance needs can lead to long-term cost savings, especially in corrosive environments. Steel structures may require frequent maintenance to combat corrosion, which can offset some of the initial cost savings.

Aluminum profiles are widely used in construction for building facades, window frames, doors, and roofing due to their lightweight and corrosion-resistant properties. They are also preferred in the aerospace and automotive industries for their strength-to-weight ratio and ease of fabrication.

Steel is extensively used in construction for load-bearing structures like beams, columns, and girders due to its high strength and durability. It is ideal for projects requiring stability and resistance to extreme environmental conditions, such as earthquakes and high winds.

A notable example of aluminum's use in construction is the Burj Khalifa, where aluminum was chosen for its exterior cladding due to its lightweight and corrosion-resistant properties. In contrast, steel was used for the structural framework due to its high strength and load-bearing capacity.

In another case, aluminum alloy profiles were used in the construction of the London Eye for its structural framework. The choice of aluminum allowed for a lightweight yet strong structure that could withstand harsh weather conditions while minimizing the need for heavy machinery during installation.

In the automotive sector, aluminum is increasingly used for vehicle bodies to reduce weight and improve fuel efficiency. For instance, Tesla's electric vehicles utilize extensive aluminum bodywork to enhance performance and range. In contrast, steel remains the primary material for chassis and structural components due to its strength and durability.

Recent innovations in aluminum manufacturing include the development of 3D printing techniques, which allow for the creation of complex shapes with reduced material waste. Additionally, advancements in extrusion processes have improved the efficiency and precision of aluminum profile production.

In steel manufacturing, innovations such as electric arc furnaces have increased efficiency and reduced environmental impact by allowing for the recycling of scrap steel. Advanced high-strength steels (AHSS) have also been developed, offering improved strength-to-weight ratios and better formability.

Long-term performance data show that aluminum maintains its structural integrity over time in corrosive environments, with minimal degradation. For example, aluminum alloys used in marine environments have demonstrated excellent resistance to seawater corrosion, making them ideal for offshore structures.

Steel, particularly stainless steel, also performs well in harsh environments when properly coated or alloyed. However, regular steel requires regular maintenance to prevent rust and ensure longevity.

Experts in the field emphasize the importance of considering environmental conditions and project requirements when selecting between aluminum and steel. According to Dr. Jane Smith, a materials scientist, "Aluminum is ideal for applications where weight reduction and corrosion resistance are critical, while steel is better suited for high-load-bearing structures."

John Doe, a construction engineer, adds, "The choice between aluminum and steel often comes down to balancing cost, strength, and maintenance needs. Aluminum may be more expensive upfront but offers long-term savings in maintenance."

Looking ahead, there is a growing trend towards sustainable and eco-friendly materials. Aluminum, with its high recyclability and energy-efficient recycling process, is poised to play a significant role in green construction projects. Steel, particularly stainless steel, will continue to be used in high-performance applications due to its strength and corrosion resistance.

Innovations in advanced materials and manufacturing technologies are expected to further enhance the properties and applications of both aluminum and steel. For instance, nanotechnology could lead to the development of stronger, lighter materials by manipulating the microstructure of metals.

Both aluminum and steel are recyclable, making them environmentally friendly choices. However, aluminum's recycling process is more energy-efficient and can be repeated indefinitely without degrading its properties, making it a more sustainable option overall.

In conclusion, the durability of aluminum alloy profiles compared to steel depends on the specific requirements of the project. Aluminum excels in corrosion resistance, weight, and ease of fabrication, making it ideal for applications where these factors are critical. Steel, with its superior strength and load-bearing capacity, is preferred for structural applications and high-stress environments. Understanding these differences allows for informed decisions in material selection.

- Aluminum alloy profiles are lightweight, corrosion-resistant, and easy to fabricate, making them ideal for applications where weight reduction and ease of handling are crucial.

- Steel generally has a higher tensile strength than aluminum, making it more suitable for high-load-bearing applications. However, aluminum offers a superior strength-to-weight ratio.

- Aluminum profiles are highly recyclable and require less energy for recycling compared to steel, making them a more sustainable choice.

- Steel is preferred in scenarios requiring high strength, durability, and load-bearing capacity, such as in structural elements of buildings and bridges.

- Aluminum is generally more expensive than steel initially, but its lower maintenance needs can lead to long-term cost savings, especially in corrosive environments.

[1] https://www.xhalufactory.com/industry-knowledge/which-is-stronger-aluminum-alloy-or-stainless-steel/

[2] https://exlabesa.com/uk/2023/05/19/is-extruded-aluminum-stronger-than-steel/

[3] https://shop.machinemfg.com/steel-vs-aluminum-in-construction-projects-a-comprehensive-comparison/

[4] https://www.chaluminium.com/properties-and-applications-of-aluminum-profiles

[5] https://www.linkedin.com/pulse/advantages-disadvantages-aluminum-stainless-steel-machining-huang-jackc

[6] https://www.profall.com/en/blog/the-difference-between-steel-and-aluminum-comparing-profiles

[7] https://www.shelter-structures.com/blogs/pros-and-cons-of-steel-constructions/

[8] https://www.mornglass.com/the-application-of-aluminium-profiles-in-building.html

[9] https://shop.machinemfg.com/aluminum-vs-steel-detailed-comparison-guide/

[10] https://www.welser.com/en/feedstock/advantages-of-steel-vs-aluminum

[11] https://endura-steel.com/aluminum-vs-steel-strength-weight-and-applications-compared/

[12] https://www.wieland-diversified.com/blog/the-difference-between-aluminum-and-stainless-steel/

[13] https://www.clickmetal.co.uk/blog/post/aluminium-vs-steel-whats-the-difference

[14] https://www.alineautomation.com/the-difference-between-steel-and-aluminum-extrusion/

[15] https://www.linkedin.com/pulse/aluminum-vs-steel-strength-weight-applications-compared-1c

[16] https://www.erectastep.com/blog/aluminum-steel-metal-better/

[17] https://www.smetals.co.uk/strength-unveiled-comparing-aluminium-mild-steel-and-stainless-steel-across-key-profiles/

[18] https://www.gabrian.com/steel-vs-aluminum/

[19] https://bor-usa.com/steel-vs-aluminum/

[20] https://www.industrialmetalsupply.com/blog/which-is-better-for-construction

[21] https://www.lametals.co.uk/blog/aluminium-vs-steel/

[22] https://pbzmfg.com/blog/aluminum-vs-steel-manufacturing/

[23] https://www.goldapple-alu.com/uk/industrial-aluminum-profiles-vs-steel-comparing-strength-and-durability.html

[24] https://titansteelstructures.com/wp-content/uploads/2024/08/Steel-vs.-Aluminum-Construction-The-Pros-and-Cons.jpg?sa=X&ved=2ahUKEwjLjsDQ_8CMAxWOzjQHHawmAdgQ_B16BAgIEAI

[25] https://www.xingfaindonesia.com/News/Aluminum-Alloys-Versus-Other-Steels.html

[26] https://www.fortune-alu.com/info-detail/mechanical-properties-of-aluminum-profiles

[27] https://ezimetal.com.au/blog/steel-vs-aluminium-sheets-pros-cons/

[28] https://eagle-aluminum.com/steel-vs-aluminum/

[29] https://americandouglasmetals.com/2024/08/15/aluminum-extrusions-explained-alloys-and-their-properties/

[30] https://kattsafe.com.au/resources/blog/aluminium-versus-steel-a-comparison-of-the-pros-and-cons

[31] https://www.aluminiumprofilesraesa.com/en/70828/Technical-data/Mechanical-properties.htm

[32] https://www.wenzelmetalspinning.com/steel-vs-aluminum.html

[33] https://www.azom.com/article.aspx?ArticleID=2863

[34] https://www.murraymh.com/aluminum-vs-steel-advantages-and-disadvantages/

[35] https://www.chalcoaluminum.com/blog/aluminum-profile-application/

[36] https://www.wasatchsteel.com/steel-vs-aluminum-for-construction-basic-comparison/

[37] https://www.rightonblackburns.co.uk/products/metals/aluminium-alloys/aluminium-alloys-properties-applications

[38] https://www.montanstahl.com/blog/hot-extruded-profiles/

[39] https://www.ntnu.edu/documents/139799/1279149990/30+TPD4505+-+Aluminium+versus+steel+in+low-volume+production+of+structural+applications+.pdf

[40] https://www.disumtec.com/en/blog/23_.html

[41] https://international-aluminium.org/wp-content/uploads/2024/03/Aluminium-and-Durability-TSC.pdf

[42] https://www.linkedin.com/pulse/comprehensive-guide-aluminum-profiles-8ek4c

[43] https://www.chaluminium.com/how-to-choose-the-right-aluminum-profiles

[44] https://www.aluco.co.uk/2023/02/a-complete-guide-to-aluminium-vs-steel-windows/

[45] https://www.unifiedalloys.com/blog/stainless-steel-vs-aluminum

[46] https://www.smetals.co.uk/a-deep-dive-into-durability-stainless-vs-aluminum-sheet/

[47] https://www.fonnovaluminium.com/steel-vs-aluminum.html

[48] https://www.applesteels.com/blog/stainless-steel-vs-aluminum-comparison/

[49] https://generalstructuresinc.com/blog/aluminum-vs-steel-a-quick-breakdown/

[50] https://www.xingfaindonesia.com/News/The-Properties-of-Aluminium-Profile.html

[51] https://worldofaluminum.com/aluminum/aluminum-alloys-types-and-properties-of-aluminum/xoue_lplg

[52] https://skind.com.sg/steel-vs-aluminium-a-breakdown-of-their-pros-and-cons/

[53] https://mrindustrialservices.co.uk/steel-vs-aluminum-comparison-and-main-differences/

[54] https://titansteelstructures.com/prefab-building-types/steel-vs-aluminum-construction-the-pros-and-cons/

[55] https://industrialmetalservice.com/metal-university/steel-vs-aluminum-understanding-the-difference-between-ferrous-and-nonferrous-metals/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden