English

Views: 222 Author: Astin Publish Time: 2025-07-18 Origin: Site

Content Menu

● What are the differences between material columns?

● Mechanical Properties of Profiles

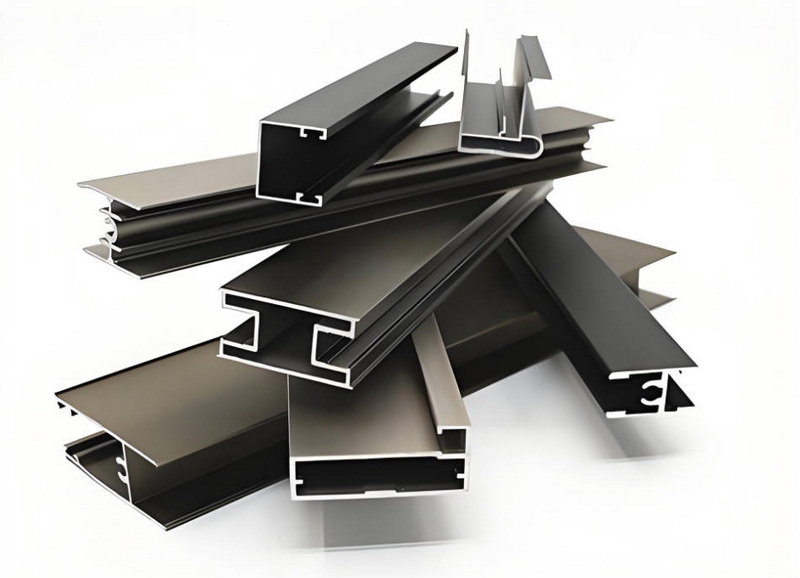

Aluminum is a very commonly specified material for extrusion and shaped profiles due to its mechanical properties, which make it highly suitable for forming and shaping metals from billet sections. Aluminum's high ductility means that the metal can be easily shaped into various cross-sections without requiring a great deal of energy during manufacturing or forming. Additionally, aluminum's melting point is typically about half that of ordinary steel. These two facts mean that the energy consumption during the extrusion of aluminum profiles is relatively low, which in turn reduces tooling and manufacturing costs. Finally, aluminum also boasts a very high strength-to-weight ratio, making it an excellent choice for industrial applications.

As a byproduct of the extrusion process, fine, almost invisible lines sometimes appear on the surface of profiles. These result from the supplementary tools used during extrusion, and additional surface treatments can be specified to remove these lines. To improve the surface finish of the profile cross-section, some secondary surface treatment operations can be performed—such as end-face milling—after the main extrusion process. These machining operations can be specified to improve the geometry of the part profile by reducing the overall surface roughness of the extrusion. Such treatments are usually specified in applications where precise part positioning is required or where fitting surfaces need to be strictly controlled.

One often sees material columns marked as 6063-T5/T6 or 6061-T4, etc. In these designations, 6063 or 6061 is the alloy grade of the aluminum profile, while T4/T5/T6 represents the temper, or condition, of the material.

For example: Simply put, aluminum profiles of the 6061 grade offer better strength and machinability, featuring high toughness, good weldability, and corrosion resistance. 6063 aluminum profiles, on the other hand, have better plasticity, which allows for higher precision in final materials. At the same time, they have higher tensile and yield strengths, exhibit better fracture toughness, and possess high strength, wear resistance, corrosion resistance, and high-temperature performance.

- T4 Temper: Solution heat treatment + natural aging, which means that after being extruded from the press and cooled, the aluminum profile is not placed in an aging furnace. Aluminum profiles in this condition have relatively low hardness and good formability, making them suitable for subsequent bending and other deformation processes.

- T5 Temper: Solution heat treatment + partial artificial aging, where the profile is air-quenched after extrusion and then held at about 200°C for 2–3 hours in an aging furnace. After cooling, the aluminum profile reaches the T5 state. This state offers higher hardness and certain deformability and is most commonly used in curtain wall applications.

- T6 Temper: Solution heat treatment + full artificial aging, which means that after extrusion and water quenching, the profile undergoes artificial aging at a higher temperature and for a longer period than T5, resulting in even higher hardness. This temper is suitable for applications that require greater material hardness.

- Yield Strength: This refers to the yield limit at which a metallic material exhibits yield phenomena, that is, the stress level at which it resists a small amount of plastic deformation. For metals with no obvious yield point, the yield limit is defined as the stress at which 0.2% residual deformation occurs, called the conditional yield strength or yield point. Any external force exceeding this limit will cause irreversible failure of the part.

- Tensile Strength: When aluminum yields to a certain degree, as the crystal grains inside rearrange, its resistance to deformation increases once again. Although the deformation develops rapidly at this point, it can only increase as the stress increases, until the maximum stress is reached. After that, the metal's ability to resist deformation drops sharply, and significant plastic deformation occurs at the weakest point, rapidly reducing the sample's cross-sectional area and causing necking until fracture occurs.

- Webster Hardness: The basic principle of Webster hardness testing uses a hardened indenter of a certain shape, which is pressed into the sample's surface by the force of a standard spring. A penetration depth of 0.01mm is defined as one Webster hardness unit. The hardness of the material is inversely proportional to the penetration depth—the shallower the indentation, the higher the hardness, and vice versa.

- Plastic Deformation: Plastic deformation is a form of deformation that is not self-recoverable. When engineering materials and parts are loaded beyond their elastic deformation range, permanent deformation occurs, meaning there will be residual deformation even after the load is removed—this is what is known as plastic deformation.

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden