English

Views: 222 Author: Astin Publish Time: 2025-04-25 Origin: Site

Content Menu

● Understanding Aluminum Frame Extrusion Profiles

>> Key Properties of Aluminum Extrusion Profiles

● How Are Aluminum Frame Extrusion Profiles Made?

>> Types of Aluminum Extrusion Profiles

● Core Benefits of Aluminum Frame Extrusion Profiles

● Major Applications of Aluminum Frame Extrusion Profiles

>> 1. Construction and Architecture

>>> Building Frames and Structures

>> 2. Automotive and Transportation

>>> Vehicle Frames and Chassis

>> 3. Industrial Machinery and Automation

>>> Assembly Lines and Workstations

>>> Machine Frames and Safety Enclosures

>>> Material Handling Equipment

>> 4. Electronics and Electrical Engineering

>>> Heat Sinks

>>> Cable Management

>>> Solar Panel Mounting Systems

>> 6. Consumer Goods and Furniture

>>> Sports and Recreational Equipment

>> 7. Specialized and Emerging Applications

>>> Aerospace

● Why Aluminum Extrusion Profiles Are Preferred Across Industries

● FAQ: Aluminum Frame Extrusion Profiles

>> 1. What are the main advantages of using aluminum extrusion profiles over steel?

>> 2. How are aluminum extrusion profiles customized for specific applications?

>> 3. In which industries are aluminum extrusion profiles most commonly used?

>> 4. Are aluminum extrusion profiles suitable for outdoor or marine environments?

>> 5. What are T-slot aluminum extrusion profiles, and why are they popular in manufacturing?

Aluminum frame extrusion profiles are at the heart of modern engineering and design, serving as the backbone for countless products and structures across industries. Their unique combination of strength, lightness, corrosion resistance, and design flexibility has made them indispensable in fields ranging from construction and transportation to electronics and renewable energy. This article explores in detail what aluminum frame extrusion profiles are, how they are made, their key benefits, and—most importantly—the diverse applications that make them a cornerstone of contemporary manufacturing and architecture.

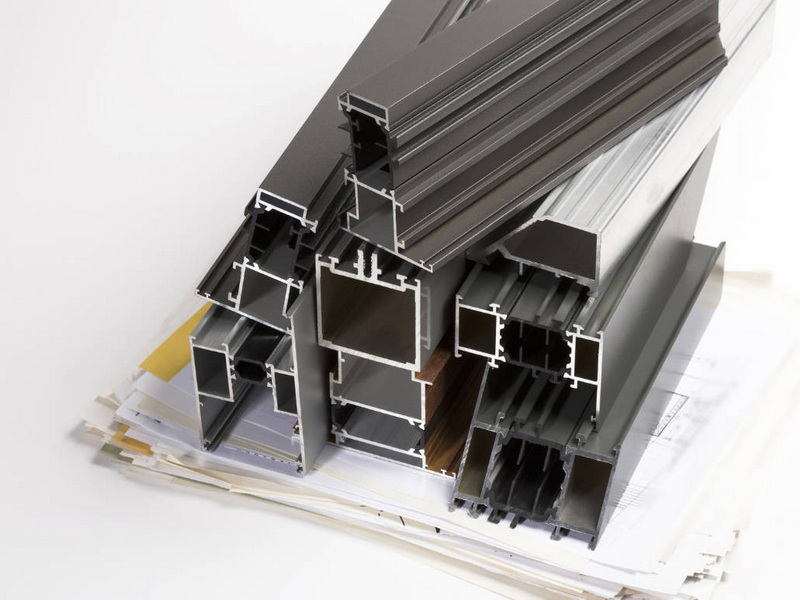

Aluminum extrusion profiles are continuous cross-sectional shapes produced by forcing heated aluminum alloy through a die. This process creates long, uniform pieces with specific shapes—ranging from simple angles and channels to intricate, custom-designed geometries. These profiles are then cut, machined, and finished according to their intended use[1][8].

- Lightweight yet strong: Aluminum's high strength-to-weight ratio makes it ideal for applications where both durability and low weight are essential[1].

- Corrosion resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and environmental degradation[1][5].

- Design flexibility: Extrusion allows for complex, custom shapes, enabling engineers and architects to realize innovative designs[1][8].

- Eco-friendly: Aluminum is 100% recyclable without loss of quality, supporting sustainable manufacturing[7].

- Cost-effective: The extrusion process is efficient, and the resulting profiles often reduce the need for additional fabrication or assembly steps[1].

The aluminum extrusion process involves heating a billet of aluminum alloy to a malleable state and then forcing it through a die with the desired cross-sectional shape. As the aluminum emerges, it takes on the shape of the die. The extruded profile is then cooled, straightened, and cut to length. Additional processes such as anodizing, painting, or machining may follow to enhance appearance or functionality[8].

- Solid profiles: No enclosed voids (e.g., angles, channels, beams).

- Hollow profiles: Enclosed voids (e.g., tubes, rectangular or square profiles).

- Semi-hollow profiles: Partial voids or complex shapes.

Each type can be tailored to specific mechanical, structural, or aesthetic requirements[4].

Aluminum's strength-to-weight ratio is one of its defining characteristics. Structures built with aluminum extrusions can be robust yet significantly lighter than those made with steel or other metals, reducing transportation costs and easing installation[1][3].

The natural oxide layer that forms on aluminum surfaces protects against moisture and many chemicals, making extruded profiles ideal for outdoor, marine, or industrial environments where corrosion is a concern[1][5].

Extrusion enables the creation of complex cross-sections that would be difficult or impossible to achieve with other manufacturing methods. This flexibility supports custom solutions for unique architectural, automotive, or industrial needs[1][3].

Aluminum is infinitely recyclable, and the extrusion process itself is energy-efficient. Many manufacturers use recycled aluminum, further reducing the environmental impact of construction and manufacturing projects[7].

Aluminum profiles often feature modular designs (such as T-slots) that facilitate quick assembly, reconfiguration, and integration with other materials. This modularity is especially valuable in manufacturing and automation[2].

Aluminum extrusion profiles are found in virtually every sector of modern industry. Below, we examine their most prominent uses.

Aluminum profiles are widely used in the construction of building frameworks, curtain walls, window and door frames, and roofing systems. Their strength, lightness, and resistance to weathering make them ideal for both structural and decorative applications[3][6].

Extruded aluminum frames support glass panels in curtain wall systems, providing sleek, modern aesthetics while maintaining structural integrity. The profiles can be anodized or painted to match any design scheme[3][6].

Aluminum profiles are used for partition walls, suspended ceilings, handrails, and decorative trims, offering both functionality and contemporary style[6].

The automotive industry leverages aluminum extrusions to reduce vehicle weight, thereby improving fuel efficiency and performance. Profiles are used in chassis, roof rails, bumpers, and crash management systems[4][5][6].

Aluminum profiles are essential in railway carriages, subway cars, and buses, where weight reduction translates to energy savings and increased payloads[4][5].

Boats and ships use extruded aluminum for masts, railings, and structural components due to its corrosion resistance in harsh marine environments[4].

Extruded aluminum profiles form the backbone of modular assembly lines, workbenches, and conveyor systems. Their T-slot designs allow for rapid assembly and reconfiguration, supporting lean manufacturing and automation[2][6].

Profiles are used to build frames for industrial machines, safety guards, and operator enclosures, ensuring both structural support and worker protection[2][4].

Conveyor frames, storage racks, and lift-assist structures benefit from the rigidity and modularity of aluminum extrusions[2].

Aluminum's excellent thermal conductivity makes extruded profiles the material of choice for heat sinks in computers, audio/visual equipment, LED lighting, and power electronics[4][5].

Lightweight, non-magnetic, and corrosion-resistant, aluminum profiles are used for electronic device enclosures, server racks, and protective housings for sensitive equipment[4][5].

Extruded tubing and channels house and protect electrical wiring, especially where electromagnetic interference must be minimized[5].

Aluminum profiles provide lightweight, corrosion-resistant frameworks for mounting solar panels on rooftops or ground installations, supporting the rapid expansion of solar energy worldwide[4].

Profiles are used in the frames, supports, and housings of wind turbines, where strength and weather resistance are critical[4].

Aluminum extrusion profiles are increasingly popular in the manufacture of modular office furniture, shelving systems, and display units, offering both durability and modern aesthetics[4].

Bicycle frames, tent poles, and fitness equipment often rely on aluminum extrusions for their combination of lightness and strength.

Aircraft frames, fuselage structures, and interior components benefit from the weight savings and structural integrity of aluminum extrusions[1][4].

Extruded aluminum is used for antenna masts, satellite dishes, and protective enclosures for sensitive communications equipment[5].

The high reflectivity of aluminum makes it ideal for lighting fixtures, reflectors, and shielding against electromagnetic or infrared radiation[5].

The prevalence of aluminum extrusion profiles is no accident. Their unique combination of properties addresses the most demanding requirements of modern engineering:

- Strength and lightness enable structures that are both robust and easy to handle.

- Corrosion resistance ensures longevity even in harsh environments.

- Design flexibility supports innovation and customization.

- Ease of assembly reduces labor costs and supports modular construction.

- Sustainability aligns with global trends toward eco-friendly manufacturing.

Whether in the soaring glass facades of skyscrapers, the sleek lines of electric vehicles, or the precision frameworks of automated factories, aluminum extrusion profiles are shaping the future of design and manufacturing.

Aluminum frame extrusion profiles are a foundational technology in the modern world. Their versatility, strength, and adaptability have made them essential in construction, transportation, electronics, renewable energy, and beyond. As industries continue to demand lighter, stronger, and more sustainable solutions, the role of aluminum extrusions will only grow.

From the skeleton of a skyscraper to the chassis of an electric car, from the frame of a solar panel to the heat sink in your computer, aluminum extrusion profiles are everywhere—quietly enabling progress, innovation, and sustainability.

Aluminum extrusion profiles are significantly lighter than steel, making them easier to transport and install. They offer excellent corrosion resistance without the need for additional coatings, and their design flexibility allows for complex, custom shapes that are difficult to achieve with steel. Additionally, aluminum is fully recyclable and supports sustainable manufacturing practices[1][3][5].

Customization is achieved by designing dies with the desired cross-sectional shape and by employing various finishing processes such as anodizing, painting, or powder coating. Profiles can also be machined, drilled, or cut to precise lengths, and modular systems like T-slots allow for rapid assembly and reconfiguration[1][8].

Aluminum extrusion profiles are widely used in construction (building frames, window and door systems), automotive and transportation (vehicle frames, railway cars), industrial machinery (assembly lines, machine guards), electronics (heat sinks, enclosures), renewable energy (solar panel mounts), and consumer goods (furniture, sports equipment)[1][2][4][5][6].

Yes, aluminum's natural oxide layer provides excellent corrosion resistance, making extruded profiles ideal for outdoor structures and marine applications. They withstand exposure to moisture, salt, and UV radiation better than many other metals[1][4][5].

T-slot profiles feature a modular design with channels (T-slots) that allow for easy attachment of components using standard fasteners. This system supports quick assembly, adjustment, and expansion of workstations, machine frames, safety enclosures, and more—making it highly popular in industrial and automation settings[2][6].

[1] https://profiledecor.com/aluminum-extrusion-profiles/

[2] https://proax.ca/en/blog/post/aluminum-extrusion-manufacturing-applications

[3] https://www.aluminumcustom.com/blog-Blog-11407/Top-Ten-Benefits-of-Using-Aluminum-Profiles-for-Your-Next-Construction-Project-11883859.html

[4] https://bor-usa.com/navigating-the-world-of-aluminum-extrusion-profiles/

[5] https://www.hydro.com/us/us/aluminum/products/extruded-profiles/north-america-resources/extruded-aluminum-products/uses-of-aluminum-extrusions/

[6] https://www.tuli-shop.com/blog/aluminum-extrusion-and-applications-guide.html

[7] https://amcaluminum.ph/common-applications-of-aluminum-extrusion/

[8] https://www.zetwerk.com/aluminum-extrusions/

[9] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[10] https://www.profall.com/en/what-is-an-aluminum-profile

[11] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[12] https://nalbantal.com/en/importance-of-aluminium-extrusion-profiles/

[13] https://mpg.co.id/aluminium-extrusion-products-around-us/

[14] https://abc-aluminum.com/types-of-aluminum-extrusion-profiles-and-form-of-use/

[15] https://bor-usa.com/what-are-aluminum-extrusions-used-for/

[16] https://haluminium.com/Products/extruded-aluminium-profiles-application/

[17] https://americandouglasmetals.com/2023/08/08/the-power-of-aluminum-extrusion-profiles-unleashing-commercial-potential/

[18] https://simmal.com/10-surprising-uses-for-aluminium-extrusion-you-didnt-know/

[19] https://www.zahit.com.tr/what-is-aluminum-profile-what-are-its-usage-areas-and-features

[20] https://www.chalcoaluminum.com/blog/aluminum-profile-application/

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden