English

Views: 222 Author: Astin Publish Time: 2025-03-24 Origin: Site

Content Menu

● Understanding Aluminum Profile End Caps

>> What is an Aluminum Profile End Cap?

>> Types of Aluminum Profile End Caps

>> Benefits of Using Aluminum Profile End Caps

>> Measuring the Aluminum Profile

>> Preparing the Aluminum Profile

● Step-by-Step Installation Guide

>> Installing Plastic End Caps

>> Installing Aluminum End Caps

>> Installing End Caps with Fasteners

>> Additional Tips for Installation

● Troubleshooting Common Issues

>> End Cap Cracking or Breaking

● Applications of Aluminum Profile End Caps

● FAQ

>> 1. What is the primary purpose of an aluminum profile end cap?

>> 2. What tools are needed to install an aluminum profile end cap?

>> 3. How do I measure an aluminum profile for the correct end cap size?

>> 4. What should I do if the aluminum profile end cap does not fit properly?

>> 5. How can I prevent aluminum profile end caps from coming loose?

Aluminum profile end cap installation is a critical step in ensuring the safety, durability, and aesthetic appeal of various structures. These end caps serve multiple purposes, from protecting the open ends of aluminum profiles to enhancing the overall finish of a project. Whether you are working on modular construction, machine frames, furniture, or DIY projects, understanding how to properly install an aluminum profile end cap is essential. This article provides a comprehensive guide, covering everything from selecting the right end cap to the final installation steps, ensuring a professional and long-lasting result.

An aluminum profile end cap is a component designed to seal and protect the open ends of aluminum profiles. Typically made from plastic or aluminum, these caps provide a neat, finished look while preventing dirt, dust, moisture, and mechanical damage from entering the profile. They are widely used in various applications, including construction, mechanical engineering, furniture making, and DIY projects.

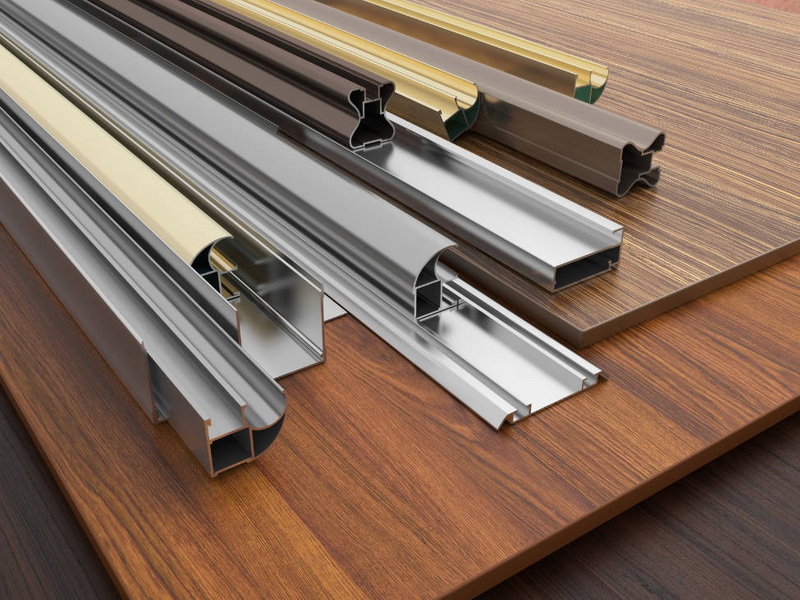

Aluminum profile end caps come in various designs and materials, each suited for specific applications. The primary types include:

- Plastic End Caps: Made from durable plastics like polyethylene, thermoplastic rubber, or ABS, these caps are versatile and offer good resistance to slippage and environmental conditions. They are easy to install and provide a clean finish.

- Aluminum End Caps: Constructed from aluminum, these caps offer enhanced durability and protection, especially in heavy-duty applications. They can withstand significant loads and provide a robust seal.

- End Caps with Fasteners: Some end caps come with built-in stems, push pins, or set screws for secure attachment. These are ideal for applications requiring a more permanent fit.

- End Caps with Openings: Certain end caps feature openings for inserting components or running cables, providing added functionality.

- Self-Locking Caps: These caps have an integrated locking pin that secures them in place, even under demanding conditions.

Incorporating aluminum profile end caps into your projects offers numerous advantages:

- Protection: End caps shield the profile ends from dirt, dust, moisture, and mechanical damage, extending the lifespan of the structure.

- Safety: They cover sharp edges and rough terminations, preventing scratches and cuts, thus ensuring a safer environment.

- Aesthetics: End caps provide a clean and professional finish, enhancing the overall appearance of the structure.

- Durability: High-quality end caps made from robust materials offer excellent resistance to heat, chemicals, and UV radiation.

- Versatility: Available in various sizes and designs, end caps can be used in a wide range of applications, from modular construction to furniture making.

Before starting the installation process, gather all the necessary tools and materials. This will ensure a smooth and efficient workflow. Here is a list of essential items:

- Aluminum Profile End Caps: Choose the appropriate type and size of end caps for your specific aluminum profiles.

- Rubber Mallet: Used for gently tapping the end caps into place without damaging them.

- Measuring Tools: A vernier caliper or ruler to accurately measure the dimensions of the aluminum profile.

- Cutting Tools: A saw suitable for cutting metal if the aluminum profile needs to be trimmed to size[1].

- Drill and Screwdriver: Depending on the type of end cap, you may need these tools for drilling holes and fastening screws[1].

- Safety Gear: Wear safety glasses and gloves to protect yourself during the installation process.

- Cleaning Supplies: A clean cloth and suitable cleaning solution to prepare the aluminum profile surface.

Accurate measurement is crucial for selecting the correct size of aluminum profile end caps. Follow these steps to measure your aluminum profile accurately:

1. Measure External Dimensions: Use a vernier caliper to measure the outside dimensions of the aluminum profile. Note the width and height.

2. Measure Wall Thickness: Determine the wall thickness of the aluminum profile. This measurement is essential for ensuring a proper fit.

3. Identify Edge Type: Check whether the aluminum profile has a square or radius edge. This will help you choose the correct type of end cap.

4. Record Measurements: Write down all measurements to ensure you purchase the correct size of aluminum profile end caps. For example, a measurement might be represented as 50x50x3 R6, where 50mm is the outside dimension, 3mm is the wall thickness, and R6 indicates a 6mm radius edge

Proper preparation of the aluminum profile is essential for a successful end cap installation. Follow these steps to prepare the profile:

1. Clean the Profile: Use a clean cloth and a suitable cleaning solution to remove any dirt, dust, or grease from the aluminum profile surface. This ensures a ভালো adhesion and a clean finish.

2. Deburr the Edges: If the aluminum profile has any sharp edges or burrs from cutting, use a deburring tool to smooth them out. This prevents damage to the end cap and ensures a snug fit.

3. Ensure Correct Length: Verify that the aluminum profile is cut to the desired length. If necessary, use a saw suitable for cutting metal to trim the profile to the correct size[1].

4. Check for Damage: Inspect the aluminum profile for any signs of damage, such as dents or bends. Address any issues before proceeding with the installation.

Plastic end caps are generally easy to install, making them a popular choice for many applications. Follow these steps for a successful installation:

1. Position the End Cap: Align the plastic end cap with the open end of the aluminum profile. Ensure that it is properly oriented and ready to be inserted.

2. Tap into Place: Use a rubber mallet to gently tap the end cap into the aluminum profile. Apply even pressure to ensure a snug fit without damaging the cap or the profile.

3. Check the Fit: Verify that the end cap is securely in place and fits tightly without any movement. A well-fitted end cap should provide a seamless finish.

4. Final Adjustments: Make any necessary adjustments to ensure the end cap is flush with the aluminum profile surface.

Aluminum end caps offer enhanced durability and require a slightly different installation process:

1. Position the End Cap: Align the aluminum end cap with the open end of the aluminum profile. Ensure correct alignment for a seamless fit.

2. Secure with Fasteners: Depending on the design, aluminum end caps may require screws or other fasteners. Use a drill to create pilot holes if necessary, and then secure the end cap with the appropriate screws[1].

3. Tighten Screws: Tighten the screws evenly to ensure the end cap is firmly attached to the aluminum profile. Avoid over-tightening, which can damage the cap or the profile.

4. Check Stability: Verify that the end cap is securely in place and does not move. The fit should be tight and stable, providing maximum protection.

Some end caps come with built-in fasteners such as stems, push pins, or set screws. Here's how to install them:

1. Stem or Push Pin End Caps: Align the end cap with the aluminum profile and insert the stem or push pin into the profile. Use a rubber mallet to gently tap the end cap until it is securely in place.

2. Set Screw End Caps: Position the end cap on the aluminum profile and tighten the set screw. The screw will expand the stem on the back of the end cap, securing it to the profile.

3. Check the Fit: Ensure that the end cap is firmly attached and does not move. The connection should be tight and secure.

- Use a Lubricant: Applying a small amount of lubricant, such as silicone spray, can make it easier to insert the end cap into the aluminum profile.

- Ensure Proper Alignment: Proper alignment is crucial for a seamless finish. Take your time to align the end cap correctly before tapping or fastening it into place.

- Avoid Excessive Force: Do not use excessive force when installing end caps, as this can damage the cap or the aluminum profile.

- Check for Compatibility: Always ensure that the end caps are compatible with the aluminum profiles you are using. Refer to the manufacturer's specifications for guidance.

- Verify Measurements: Double-check the measurements of the aluminum profile and compare them to the end cap specifications.

- Check for Obstructions: Ensure that there are no obstructions inside the aluminum profile that are preventing the end cap from fitting properly.

- Adjust the End Cap: If the end cap is slightly too large, you may be able to trim it down with a sharp knife or file.

- Use a Different End Cap: If you are unable to make the end cap fit, try using a different size or type of end cap.

If the end cap comes loose after installation, try these solutions:

- Clean the Surfaces: Ensure that the surfaces of both the end cap and the aluminum profile are clean and free of debris.

- Use Adhesive: Apply a small amount of adhesive, such as epoxy or construction adhesive, to the end cap before inserting it into the aluminum profile.

- Tighten Fasteners: If the end cap is secured with screws, make sure they are properly tightened.

- Replace the End Cap: If the end cap continues to come loose, it may be necessary to replace it with a new one.

If the end cap cracks or breaks during installation, consider the following:

- Use a Rubber Mallet: Always use a rubber mallet when installing end caps to avoid damaging them.

- Avoid Excessive Force: Do not use excessive force when installing end caps.

- Check for Defects: Inspect the end cap for any signs of defects before installation.

- Use a Higher Quality End Cap: If you are experiencing frequent issues with end caps cracking or breaking, consider using a higher quality end cap made from more durable materials.

Aluminum profile end caps are used in a wide variety of applications across numerous industries:

- Modular Construction: Providing a clean and secure finish for frames and structures.

- Mechanical Engineering: Protecting profile ends in machine frames and industrial applications.

- Furniture Making: Enhancing the aesthetic appeal of tables, shelves, and workbenches.

- DIY Projects: Offering a professional end cap solution for home improvement projects.

- LED Lighting: Installing end caps on LED aluminum profiles to protect LED strip ends and provide a clean finish[1].

- Metal Structures: Ensuring safety and providing grip or support in metallic structures.

Proper installation of aluminum profile end caps is crucial for ensuring the longevity, safety, and aesthetic appeal of various projects. By understanding the different types of end caps, preparing the aluminum profile correctly, and following the step-by-step installation guide, you can achieve a professional and durable finish. Whether you are working on modular construction, furniture making, or DIY projects, mastering the installation of aluminum profile end caps will enhance the quality and appearance of your work. Always remember to use the right tools, take accurate measurements, and follow safety precautions to ensure a successful outcome.

The primary purpose of an aluminum profile end cap is to protect the open ends of aluminum profiles from dirt, dust, moisture, and mechanical damage. It also provides a neat and finished appearance.

The essential tools include aluminum profile end caps, a rubber mallet, measuring tools, cutting tools (if needed), a drill and screwdriver (depending on the end cap type), safety gear, and cleaning supplies[1].

Measure the external dimensions (width and height) and wall thickness of the aluminum profile. Also, note whether the profile has a square or radius edge.

Double-check the measurements, ensure there are no obstructions inside the profile, and consider trimming the end cap or using a different size or type.

Ensure the surfaces are clean, use adhesive, tighten fasteners (if applicable), and consider replacing the end cap if it continues to come loose.

[1] https://www.topledprofile.com/blog/a-step-by-step-guide-on-how-to-install-led-aluminum-profiles-230810c8-04eb-4951-a464-467a158c05d8

[2] https://www.ultratradeframes.co.uk/wp-content/uploads/2019/08/ALUMINIUM-ROOF-INSTALLATION.pdf

[3] https://www.vst-lighting.com/installing-aluminium-profiles-for-led-tape/

[4] https://gtech-shop.de/Aluminum-profile-end-cap

[5] https://fortaps.com/blog/en/benefits-external-end-caps-metal-structures/

[6] https://www.modularcomponents.com.au/building-blocks/end-caps/

[7] https://novo3d.in/aluminium-profile-end-cap/

[8] https://www.nelsonscnc.com.au/pages/faq

[9] https://nelsonscnc.com/pages/how-to-install

[10] https://www.svetoch.eu/en/produkt/aluminium-end-cap-svetoch/

[11] https://www.minitecautomation.com/products/profile-system/end-caps

[12] https://nelsonscnc.com/pages/faq

[13] https://www.youtube.com/watch?v=vuldrimMcqI

[14] https://www.domtek.ca/wp-content/uploads/2024/03/verolite-base-cap-install-guide-domtek.pdf

[15] https://www.doityourself.com/stry/how-to-install-aluminum-gutter-end-caps

[16] https://www.youtube.com/watch?v=KtCw9dW3gmk

[17] http://www.valuframe.co.uk/End-Caps.html

[18] https://www.alibaba.com/showroom/end-caps-aluminium-profile.html

[19] https://www.item24.com/en-de/profile-end-cap-8-40x40-grey-similar-to-ral-7042-71483

[20] https://www.traceparts.com/en/product/kanya-ag-aluminium-profile-system-end-cap-30x30?Product=90-03052019-043214

[21] https://hultafors.com/en-gb/blogs/articles/profile-and-end-caps

[22] https://www.emicorp.com/products/83/End-Caps/

[23] https://autled.com/daten/anleitung/Recessed%20profile%20mounting%20instructions.pdf

[24] https://www.lumenalights.com/outdoor-lighting/extruded-aluminium-profile-end-caps-pack-2/

[25] https://synrise.en.made-in-china.com/product/CFbGDKMAwwpN/China-PVC-Aluminum-Profile-Accessory-End-Caps.html

[26] https://www.lumistrips.com/aluminium-profile-end-cap-open-deep-33785-html.html

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden