English

Views: 0 Author: Site Editor Publish Time: 2022-11-21 Origin: Site

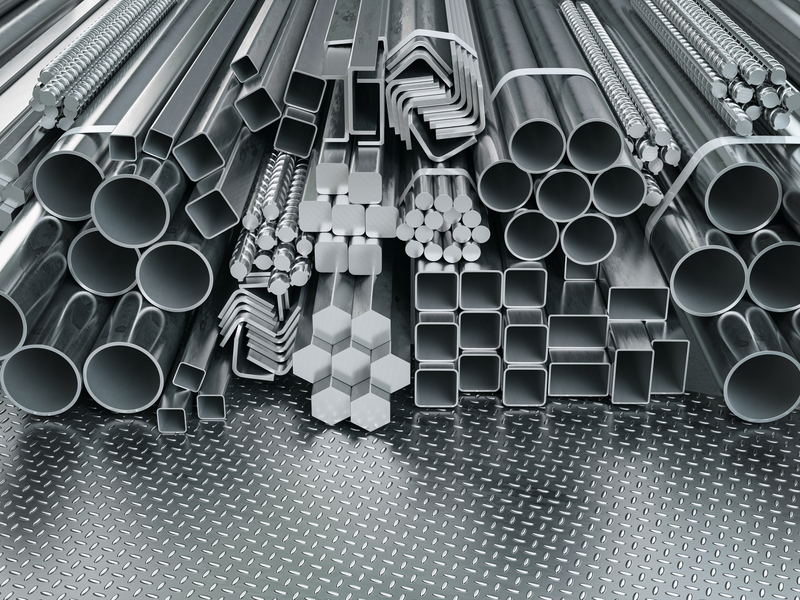

Aluminum, that metal we come across everyday, plays a vital role in various aspects of our lives. It's a material in the construction industry, a component in manufacturing appliances and even finds its way into everyday consumer goods.. You know what? There's more to aluminum than what meets the eye. Today let's embark on a journey to explore the differences between aluminum and its flamboyant counterpart. Extruded aluminum. So buckle up because we're about to go on an adventure!

Lets kick things off with some excitement as we dive into the captivating realm of aluminum. Imagine this; machines casting and shaping this metal into a wire form. Then they heat it up, giving it a transformation before it cools down and becomes a feather light sheet. These sheets can take on any shape or form surpassing what standard aluminum can only imagine. Extruded aluminum truly shines like a rock star, in the world of metals!

Now Introducing Regular Aluminum. The Suspect

On the other hand we have regular aluminum – also referred to as "pitched" or "fat" grade.

When it comes to aluminum it usually showcases itself in a "grade although there are occasions when they do overlap. So what makes these two different from each other?

Breaking it Down: Composition Clash

First, let's talk about ingredients! Regular aluminum is pure, elemental aluminum, containing nothing but its metallic essence. On the contrary, extruded aluminum is a bit of a rebel; it flaunts a 50% carbon content, with only about 5% elemental aluminum in its makeup. That's like comparing a plain cheese pizza to a deluxe with all the toppings!

Now, onto the production showdown. Regular aluminum is the product of casting, where molten metal gets poured into molds, left to solidify, and voila! Extrusion, on the other hand, is the process of squeezing molten metal through a die, the same die used for making molds. It's like turning up the heat and precision to eleven. But here's the twist - it requires scorching temperatures, so it's a "furnace-only" kind of deal.

Let's talk about muscles. Extruded products flex their strength muscles more than their cast counterparts. Why? Well, it's because they're less stressed out internally due to fewer imperfections in their design or manufacturing process. Think of it as the difference between a stress-free yoga guru and someone dealing with a hectic commute.

Regular aluminum is the cool, cylindrical type, while extruded aluminum is a bit of a shape-shifter. Depending on the manufacturer's whims, it can go fat or round. It's like comparing a classic car to a sleek sports car; they both get you there, but with different vibes!

When it comes to handling the heat, regular aluminum is a bit of a softie. It melts at a lower temperature compared to its extruded counterpart. So, if you want your items to keep their cool shape, regular aluminum is your wingman.

Here's a brain teaser: regular aluminum is the easygoing one, easy to machine. But extruded aluminum? Not so much. It's denser than regular aluminum, so machining it is like breaking a sweat at the gym instead of a leisurely stroll in the park.

Now, let's take a peek at where extruded aluminum shines the brightest.

It's a known fact - extruded aluminum loves household appliances. Refrigerators, freezers, and air conditioners adore it for its top-notch heat conductivity. It keeps things chill when the temperature rises.

Calling all foodies! Extruded aluminum is the culinary conductor in cooktops and grills. Why? Because it can handle the heat and cook up a storm. It's like having a chef's hat on your stove.

When it comes to building boats, cars, and other vehicles, extruded aluminum is the go-to material. Its high strength-to-weight ratio ensures these vehicles are not only robust but also fuel-efficient. Talk about hitting two birds with one stone!

For industries with corrosion resistance on their checklist or those entangled in chemical processes, extruded aluminum is the knight in shining armor. It withstands the harshest of environments and chemicals, making it the MVP of the industrial world.

Now, let's not forget our old buddy, regular aluminum. It may not have all the glitz and glamor, but it's got its own fan club.

If you own an older car with a steel radiator, you can give it a makeover by swapping it out for aluminum. Just a heads-up, though - it might be a tad more prone to warping in frosty weather.

Aluminum pipes and tubes are the unsung heroes in various applications. They play vital roles in food processing equipment, water systems, and hoses. When it comes to fluid transportation, they've got it covered.

Aluminum cookware - no need for heavy-lifting. It's light, virtually indestructible and easy to clean: the three top reasons kitchen utensils should be made of aluminum. Your pots and pans have never had it so good.

Light fixtures are also an ideal choice for aluminum extrusion applications. Not only is aluminum lightweight but simple to install as well - screw in place, flick on the switch and let there be light!

Ladies and gentlemen, when it comes to extruded aluminum, there's simply no replacement. These extrusions are precision-crafted, boasting ratios of strength to thickness to weight that put other materials to shame. What's more, they can waltz into various shapes - some with curves that would make steel green with envy.

To recapitulate, aluminum extrusions are not only easy on your wallet but also on a designer's head. They beat sheets and plates hands down in being economical as well as flexible. So next time you go eyeing an aluminum product, check if it has been extruded - you might just be holding a masterpiece in your hands!

Top Aluminum Furnitures Manufacturers and Suppliers in Czech Republic

Top Aluminum Furnitures Manufacturers and Suppliers in Poland

Top Aluminum Furnitures Manufacturers and Suppliers in Belgium

Top Aluminum Furnitures Manufacturers and Suppliers in Finland

Top Aluminum Furnitures Manufacturers and Suppliers in Denmark

Top Aluminum Furnitures Manufacturers and Suppliers in Greece

Top Aluminum Furnitures Manufacturers and Suppliers in Portugal

Top Aluminum Furnitures Manufacturers and Suppliers in Austria

Top Aluminum Furnitures Manufacturers and Suppliers in Norway

Top Aluminum Furnitures Manufacturers and Suppliers in Sweden